In the last article I told you about.

Dear readers, you already know that there are several. Therefore, in today’s article we will talk about open electrical wiring in wooden house.

I have already described the advantages and disadvantages of hidden and open electrical wiring earlier in my articles. You can read it here: and.

In this article, I will not force you to make a choice in one direction or another, but I just want to tell you in detail how to correctly install open electrical wiring in a wooden house.

So let's get started.

How to properly install open electrical wiring in a wooden house?

Before installing open electrical wiring in a wooden house, first of all, you need to think in advance about the places where the electrical points will be installed. Electrical points include: switches (), lamps, lighting panels, power panels and other electrical equipment.

Secondly, you need to decide on the method of laying open electrical wiring in your home.

What methods of laying open electrical wiring exist?

Methods for laying open electrical wiring in a wooden house

There are several ways to lay open electrical wiring:

- on porcelain rollers or insulators (electrical wiring in old apartments and houses, or retro-style electrical wiring)

- on staples

- in PVC corrugation

- in PVC pipes

- V metal pipes Oh

- in a metal hose

- in PVC boxes

- in cable channels

- on cable trays

I'll give you a few illustrative examples. This is what it looks like.

![]()

You can read more about each installation method in my article.

Installation of exposed electrical wiring in a wooden house

1. Route markings

Installation of open electrical wiring must begin with markings. In addition to marking the installation locations of electrical points, it is necessary to mark the route for laying cables and wires.

Do not rush when applying markings; think carefully about each step.

Otherwise, you will have to redo the already completed electrical installation.

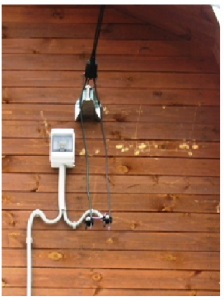

2. Installation of electrical points (sockets, switches, lamps)

At the second stage of installation of open electrical wiring it is necessary.

Attention!!! The base for mounting sockets, switches, lamps, etc. must be metal.

We cut out the metal plate (base) and attach it to the place where we planned to install the socket, switch, lamp, etc.

3. Laying wires and cables

The third stage of open installation includes laying wires and cables. We discussed ways of laying wires and cables a little higher.

I remind you that passages of wires and cables through wooden structures (ceilings, floors, walls, partitions) should ONLY be carried out THROUGH METAL CELLS (PIPES).

To install a metal sleeve in a wooden structure, you need to make a hole using. We insert a metal sleeve into this hole so that its edges on each side protrude at a distance of 1 (cm) from the wooden structure.

And after all that has been said above, we proceed to laying wires and cable lines.

For information on how to choose the cross-section of cables and wires, read the article on how to correctly and.

The laying of open electrical wiring is carried out with three-core or five-core wires, i.e. by or .

4. Connection

The fourth stage of installing open electrical wiring in a wooden house is cutting and connecting wires and cables to electrical equipment. This is done with the help of tools (I gave a link to the article about tools above in the text).

5. Completion of work

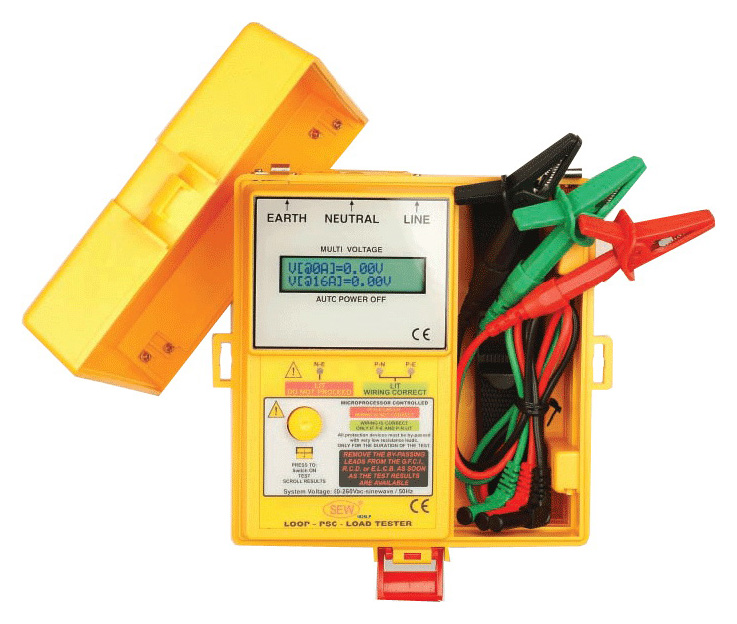

After completing the work, you need to contact electrical laboratory specialists who will carry out acceptance measurements and tests of the electrical wiring:

- RCD measurement

- etc.

After the measurements and tests have been carried out, the electrical laboratory specialists will provide you with reports in which they will write a conclusion about the condition and serviceability of your newly installed electrical wiring.

P.S. This concludes the article on the topic of exposed electrical wiring in a wooden house. Ask me your questions in the comments or in the form feedback. Subscribe to new articles.

How did you install exposed electrical wiring in a wooden house???

87 comments to the post “Exposed electrical wiring in a wooden house”

I have a hundred year old wooden house. and the wiring used to be on rollers. She is also a hundred years old, no less. Dusty and greasy. Especially in the kitchen. Now we have replaced the wiring. and all of it is in PVC cases. Just a miracle: neat, clean. easy to clean and cleaning the house is no longer scary)))

THANK YOU. I AM NOW COLLECTING INFORMATION ON THE ISSUE OF OPEN AND CLOSED ELECTRICAL WIRING IN A WOODEN HOUSE. EVERYTHING IS AVAILABLE AND EVEN CLEAR FOR ME) THE EXPLANATIONS IN THE PICTURES ARE VERY HELPING

I completely agree about VVGng-LS, many do not pay special attention to this, even they manage to lay PUNP...

I liked the antique wiring on rollers - it looks beautiful, it’s so cool)))

We were just about to change the wiring at our dacha, it’s quite old, so now we’ll do everything according to the rules.

I have two questions:

1. Is it possible to lay a VVGng-LS cable with a cross-section from 1.5mm2 to 4mm2 openly on a wooden wall (with fastening with brackets)?

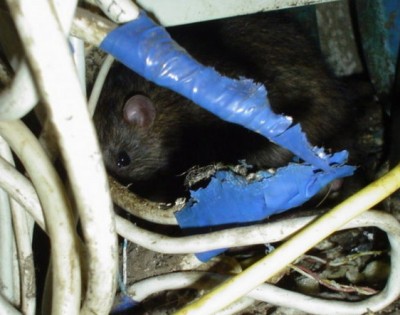

2. Is it possible to lay a VVGng-LS cable openly in a metal hose along wooden walls and ceilings in the attic (two attic options: 1) frequently visited; 2) practically none. I’m hinting about rodents).

Thanks in advance!

P.S. And in general, huge respect for your articles. Until you find the answer in books, you will forget the question...

Sergey, I’ll answer your first question. Yes you can. On the second question - I wanted to write a separate article - electrical wiring in the attic. There are special requirements for her.

Thank you for your work!

Will wait.

Hello, please tell me if there is any new way will they connect to the aluminum wires running from the pole to the house using insulators? Previously, they simply twisted the wire (aluminum) around the power supply, then they used nuts, then nuts were banned, then twisting seemed to be the same. So how to connect correctly? in the first case if we connect with copper and the second case if with aluminum. Of course, it would be nice to see the photos... These contacts are very important, there were cases, not uncommon, when the threat of fire was precisely in these contacts. The installation in the house was high-quality and competent, but due to poor contacts at the input, heating and sparking occurred. The introductory machine did not operate due to heat or EM protection.

Konstantin, currently, I recommend using SIP to introduce supply voltage into the house. Where did you get the idea that “nuts” were canceled - this type of wire connection is allowed in the PUE.

At the site, I accidentally met a theorist from Energonadzor and he told me about the nuts, that the wind makes the wire leading to the house shake, and the outside temperature causes the copper to expand and contract, and that the bot connection on the nut becomes loose and the contact is broken, and in short, everything is gone... I bet I didn’t bother with it and, just in case, I first make a twist on the power cable, and then I put a nut on the twist. I heard. that other connections appeared in place of nuts, I even saw them, black with a 10 bolt, when tightened, it clamps both the incoming wire and the one to which I connect. I wanted to ask, has anyone worked with these clamps? And SIP wire for supplying to the house (self-supporting insulated wire) in my opinion stands for this. But I need to connect from the shield inside the house through a metal tube to the wires from the insulators on the house outside. AVVG 2x10 is more suitable for me (it seems to me) and the cross-section should be enough for small house wooden…

If I find a suitable clamp to connect copper and aluminum correctly, of course I will start copper with 2x6 or 2x10, also some kind of VVGng LS

A few words about the site: of course, thank you for being there and the site is very accessible and very useful. I would like to note only one thing - in a wooden house the base of the sockets must be metal (as you write) and this is absolutely correct, and in the photo on the site - as an example of installing sockets and switches from the Etude company under wood (if I’m not mistaken with the brand) , and the study never made a metal base in sockets or switches. It’s as if someone, without reading the full description, installed the electrical wiring following the example in the photo... I’ve never seen a metal plate specially cut out for an outlet and you can’t see it in the photo.

If the manufacturer of switches and sockets does not produce them with a metal base, then it must be done independently. This is what we did at one of the objects (bathhouse) during installation. It is not visible in the photo, because... I think that aesthetics should be present in the work and making a metal plate larger than the dimensions of the socket or switch itself is impractical.

The walnut consists of three plates, so there is no direct contact between copper and aluminum; their contact occurs through a steel plate. Which is exactly what we need. So you can use nuts in your case with a clear conscience.

The clamp you are talking about is special clamps for SIP wires. I will write a detailed article about them soon.

So if I choose a SIP supply wire to the switchboard, can I connect it to aluminum from insulators with such clamps? or are they only SIP to SIP??? It’s just that when you tighten the bolt, the contacts inside the clamp come out and are quite sharp... I hope I don’t bite the aluminum from the insulators with it.

Good day!

Please tell me if there are any special connection requirements electric convectors(floor and wall) in a wooden house with new (2009) open, copper, three-wire wiring?

Tatyana, hello!!! First of all, it is necessary that the cable to the convector has the appropriate cross-section. The section is selected according to its installed capacity(according to passport). It is advisable to power it through an RCD or a differential circuit breaker of the appropriate rating. In principle, that's all. If any difficulties arise, write to me the power of your convector - I will choose electrical equipment for you.

Good health!

I would like to ask about localization ability. At closed wiring this issue is given special attention. When open, it turns out that almost nothing is spent! If with hidden wiring you need to cover the wiring on all sides with non-flammable material, then with open wiring, in my opinion, at least on the sides adjacent to flammable surfaces! Isn't it logical?

Quote: "Attention!!! The walls of corrugated PVC and plastic boxes (channels) burn out during a short circuit, which, if used in hidden electrical wiring in a wooden house, will lead to a fire.”

Question: Is there no such danger when wiring in a PVC corrugated or plastic box directly over wooden surfaces? It's kind of strange, isn't it?

PUE, PTEEP, SNiPs - these are, of course, laws for electricians; there’s no escape here.

Therefore, it seems that the most correct thing is to lay the wiring in metal pipes. However, I believe that it is almost impossible even for professionals to do it without deviating from the standards. I’m not even talking about the cost. The solution is to lay external electrical wiring.

In my opinion, there is a big myth about rodents and other animals eating wiring (maybe the electricians themselves came up with this?) And all short circuits occur from network overload, unsatisfactory network condition and other chaos.

With a correctly developed project, selection of the permissible load and, accordingly, the cross-section of wires, protection, RCD and, accordingly, high-quality installation, a plus periodic testing electrical wiring and equipment nothing will happen for 100 years.

Regarding the myth about rodents: I witnessed such ‘sabotage’. When replacing a wire (old) with a new one in the void interior partition the insulation was carefully removed from both wires. Traces of touching each other were visible on the exposed wires. The old wooden house was one step away from the fire. After this, all passages through the walls were urgently checked and metal tubes were plugged into the passage points. So this is not a myth.

Why is the boss silent?

Good afternoon.

In my wooden house on the second floor there are unheated cavities on the sides of the rooms, through which you can crawl freely. Is it possible to lay a cable in a metal conduit in them?

Igor, it is possible, if the electrical wiring is laid openly and there is access to it. But if it is an attic, then special requirements apply to electrical wiring in attics.

Igor, metal pipes are the only thing allowed. ground them and move on.

Konstantin, metal pipes with hidden wiring - I agree. But Igor did not clarify the premises and the method of laying the electrical wiring.

How to connect a switch with a socket. Show me the diagram.

Evgeniy, on given time There is no such diagram on the website.

How to mount the meter outdoors on the wall of a house and at what height? And what kind of hooks to install for the liner from the pole?

Is it mandatory to organize grounding in a wooden house when connecting to single-phase network 220v-6kW?

Nikolay, definitely.

Good afternoon! Thank you for your answer. But if you look at the essence: I have a room without increased danger, there are no water or heating pipes, no iron cabinets, etc., but if I conduct a grounding circuit and ground, for example, a microwave oven, then it appears the possibility of being hit if you accidentally touch a phase wire and a grounded device at the same time.

Nikolay, in such situations, an RCD is installed that will turn off the power if there is a current leak

Hello everyone, I live in an old wooden house, the wiring is the same old as the house, they made repairs in one room and accordingly changed the wiring to new, 2.5 sq. mm copper. (as I thought), but it turned out (after a little reading on this site) to 1.7 sq.mm., thanks to the admin for explaining such things to us mere mortals, far from electricity, for example, when I bought a wire for wiring, I knew that I need a section of 2.5 sq. mm. and bought one, but it turned out to be PUNP, so why change everything now? In the contact of copper with aluminum, heating occurs when you turn on, for example, a microwave, now I want to draw a separate line to the light, sockets and devices such as a microwave, but what about the contact with aluminum (I installed a terminal block, but it’s still some kind of nonsense), if you pull copper before the meter or before the traffic jams, then what should I do, there is aluminum there, will it heat up again or something? It's not clear! The terminal block was melting, but if you lay it to the plugs, it will start to melt in the plugs??? Thank you!

Oleg, you just need to do it quality connection copper and aluminum are all allowed. Leave the PUNP; if it has the appropriate cross-section, then use it; if the cross-section is too low, then load it a little less.

I did the electrical wiring in a wooden house at the dacha on my own. I read the article. Thanks for the valuable information. It turned out that I did the wiring correctly open method in PVC boxes. But as it turned out, he committed a number of violations. In places where they passed through wooden walls, I laid wires in PVC corrugation, which is a serious violation. In addition, sockets and switches have a plastic base that is attached to a wooden wall. I have lived with this wiring for five years during warm periods. First of all this year I will install a metal base under all sockets and switches, and in places where they pass through wooden walls I will install metal sleeves. Should the electrical panel in which the machines are located also be metal, not plastic? Or can it be plastic, but must there be a metal base for the shield? The connection point for electricity to the overhead line is not in the house, but in a separate utility unit, and from the utility unit it goes into the house with a cable that lies on a metal cable.

Hello, I have a number of questions.

1. Let’s say I’m laying new wiring with a three-wire VVG. It turns out that I have to connect my own line from the meter (panel) to each socket, since the PE conductor can only be connected to the main switch, and connected to a distribution box. no boxes?

2. Why a metal base for electrical points? Does it need to be grounded?

Stepan, good afternoon.

1. You can connect PE conductors in junction boxes

2. Do you want to attach the socket directly to a wooden surface? What about fire safety - what if you accidentally overload an outlet and it starts to heat up and melt? There is no need to ground the base.

It’s clear, but why then have a main grounding bus at all, if you can simply make branches from one PE conductor?

Hello Stepan.

It is necessary to connect the PE wire according to the standards without breaking. Because PE wire is one of the main ways to protect against electrical damage. it cannot be connected “in a loop” with current. You need to clean the core from the insulation without making a cut, screw on 2-3 threads of the same wire as the core, crimp and solder this place. All this is done in the socket box.

The second way is to use a “VAGO” clamp, in which case the core can be cut. This method is allowed by Energonadzor as an exception. But main way- this is soldering without cutting.

Good afternoon

Can you please tell me what the thickness of the metal plate installed under sockets and switches should be? For example, is regular food foil suitable or do you need something more serious? Thank you.

But this logic proposed by the PUE is really not at all clear. Those. It is strictly prohibited to use a cable duct, PVC corrugation, metal hose, etc. with a closed method of installing wiring on flammable materials (which, no matter how difficult it may be in practice, is understandable and justified) and at the same time allowing the use of the same cable duct, PVC corrugation, etc. with the open method. Does it matter: the cable will pass under wood cladding or along it, if in both cases it is in direct contact with the tree? Is this really allowed only because it is assumed that open wiring is always in sight and if something happens to it, it will be visible. Well, somehow it’s very weak for such a normative document as the PUE to rely on such assumptions in such an important matter as fire safety. Well, you really can’t expect that all the rooms in the house (of which there may be quite a few) are simultaneously under the visual control of the owner. Or what, he must constantly run around the whole house and watch, no matter where a cable channel burns out or a mouse gnaws through a PVC corrugation laid in an open way?! And if you need to leave the house, but at the same time leave some kind of load (for heating, for example)?!!! This is absolutely scary to think about!!! In general, to put it mildly, strange logic!!! I absolutely agree with Ilya (comment-question from 05/18/2013 at 21:13)

What do you think about this, Dmitry? The fact that these are the rules and you didn’t come up with them is understandable. But if you still abstract from the PUE. Just your “private opinion”?

And I would also like to know this:

Are there, in principle, ready-made sleeves available for sale for the passage of walls? Various diameters and lengths? Or you need to take simple gas pipes and make them yourself. And wouldn’t it be more correct to make the length of the pipe-sleeve such that there would be about 10 mm protruding on each side of the wall. Then cut threads at the ends and tighten this sleeve on both sides with thin nuts and washers?

Regarding metal plates for installation between switches. What should be the thickness of this plate?

In my wooden house, I simply wrapped sections of wires passing through the walls with thick metal foil (in several layers, without much tension). Installation is simplified, the wires themselves are not damaged, and there is no direct contact between the wire and wooden surfaces- same as when using metal sleeves. I also placed the same foil (2-3 layers) under switches with sockets. The most common foil is food grade.

Of course I agree, electrical wiring in a wooden house is special case(regardless of whether it is open or hidden) and fire safety should not be neglected here. On the contrary, we need to approach this issue more carefully. But the rules are the rules, and I conveyed their requirements to you. I can only speculate and guess why the requirements for open wiring are somewhat relaxed. Most likely because open wiring is always accessible for inspection, and in the event of a short circuit, the location of the short circuit will be clearly visible (traces of soot, melting), a burning smell will appear faster than a short circuit will occur in recessed places inside wooden partitions with hidden wiring.

All feed-through sleeves, bushings and adapters can be found in stores, although more often they are made to order. Well, or do it yourself - it will be much cheaper. The requirements for the thickness of the metal plate are similar to those for metal pipes for electrical wiring, i.e. with a cross-section of the supply cable up to 2.5 sq. mm, the thickness is not standardized, and with 4 sq. mm - 2.8 (mm).

Hello!

Thank you to everyone for the useful and sensible information.

Not being an expert, I'll try to guess:

- so strict requirements to hidden wiring in wooden houses is explained by the fact that houses made of logs or timber are subject to rotting over time (tens of years) and, accordingly, vertical shrinkage and horizontal displacement (leaning huts).

I myself live in such a crooked hut - the maximum displacement from the vertical (between the lower part of the wall and its upper part) is 180 mm with a wall height of 2.5 m.

It seems that hidden wiring (without steel pipes) would not have tolerated such a distortion and would have started a fire.

Apparently, PUEs are written on the basis of painful experience, just like traffic rules.

I thought: it would be nice to read the comments with pictures) to the PUE, similar to the existing commentary-clarifications to the traffic rules.

Good afternoon

Tell me, there are articles on the Internet that say that in a wooden house, each outlet requires a separate cable from the electrical panel. Do you think it is worthwhile to install electrical wiring in this way?

Sayan, these requirements are acceptable not only in a wooden house, but also in ordinary apartment. The owner decides everything here. If you want maximum reliability of power supply, while spending a decent amount on materials, then go ahead. Personally, I am in favor of this method, but it all depends on the budget and the feasibility of this decision in a particular case.

Good afternoon everyone!

Tell me if I made a mistake somewhere with mine new wiring in a wooden house.

The walls are sheathed with plasterboard (the gap from the wall is 5-10 cm. The distribution boxes are in plastic plaster, twisted, I think they can put clamps. Open wiring on the walls in cable channels, VVG ng LS cable 2.5 mm.

I want a suspended ceiling. I will run a corrugated line along the ceiling, and fill the route with fire-resistant plasterboard 12.5.

Input machine 25a.uzo 40 a, 30 mA, and two machines 16 each per room.

What mistakes did you make?

I take this issue very seriously, I don’t want to screw it up.

Good day.

They promised to tell us about the wiring in the attic - it’s certainly interesting.

But for example, I’m wondering what requirements apply to wiring in basement(especially considering that in the basement there are wooden sheds for storing various things of the residents and wooden chests for potatoes) and how to properly install the wiring there, or rather, let’s say not so much replacing all the wiring, but making a branch line to your shed and making a light and socket there ?

And at the same time, what do you think about the method of laying over combustible structures or next to them in a metal-plastic pipe (of course PVC plastic) ?, some practice.

1).Instead of a steel pipe when laying over combustible structures (SC), can you use an aluminum pipe/u with a diameter of 16 mm, a wall thickness of about 1.5 mm? (it seems that the type of metal is not indicated in the PUE or is it?)

2).As a lining on the SC under the socket/switch/junction box, you can not use steel sheet, and aluminum is about 1mm thick?

3).If there is no grounding, is it necessary to ground the metal pipe (aluminum) in which the wire runs through the electrical network if it is known that no one will touch this pipe? , and is it possible to install an RCD/diff circuit breaker if there is no ground and is it possible to turn off the RCD/diff circuit breaker if there is a phase or neutral wire short circuit to a metal pipe, but no one touches it, i.e. there will be no leakage through a person? - again, if the RCD/differential circuit breaker is not connected to the ground due to its absence.

Metal hose is prohibited for installation in wooden houses without additional fire safety measures, as it does not have localization ability. Localization ability is the ability of a CONTINUOUS STEEL pipe to withstand a short circuit flash. Read the PUE more carefully. It contains all the answers to the questions. Or hire a competent specialist if you don’t want to read.

Correction! I didn’t complete the explanation! metal hose is prohibited for hidden installation! I’ll add my own method: in the open, ensuring a distance from the combustible surface of at least 10 mm and using differential protection for such a line. The metal hose must be grounded and the resistance checked.

What if you don’t earth it, but use this sleeve as a simple thermal and mechanically protecting screen? Or earth, what will happen if double-insulated wires/cables are used?

If you do not ground, then you will lose an important component of the set of safety measures - at your own conscience. These sections of metal hose by default fall under the requirements of the PUE. All And what is so difficult about this task? Financially it’s worth it, it’s just time-consuming.

Hello! I want to replace the input in my private house myself and install an input machine. Do I need to invite electricians from the electrical network before this so that they can make sure that I haven’t broken anything in the wiring, or should I invite them after I’ve done everything so that they can seal the machine for me? and connected the wires to the meter??? Thank you!

Novel:

08/02/2015 at 09:43

You need to notify the energy sales organization, whose representatives will unseal the electric meter

Good afternoon

Please explain what you meant when you recommended placing a metal plate under an outlet or switch when wiring is open on combustible surfaces. Is this a PUE requirement? But then, in theory, the plate should simply be non-flammable - fiberglass or getinax or any other non-flammable material of appropriate thickness. And should it protrude 10 mm from the socket - as when it is required to lay a wire in flammable insulation over a combustible surface. And this requirement applies to all external sockets or only to those that are not protected by anything reverse side? And if they are hermetically sealed (IP54), is a plate also needed? The requirement for a wire distance of 10 mm from a flammable surface is fulfilled automatically, isn’t it?

Good afternoon!!! Tell me how to choose the correct cable channel size for a certain number of outgoing lines????

Good time days!

Do you think a piece of ski pole is suitable as a metal pipe to go through the wall? Or, probably, the diameter will not fit...

For your safety, or for formality?

for safety

and a lot of ski poles...

I decided to replace aluminum with copper, laid out the entire backup circuit, but I don’t know how to connect from the insulators, the indicator doesn’t show where the phase wire is - that’s the problem

Hello, I have several questions about wiring in a wooden house:

1. The article says that wiring can be done using brackets. But PUE 2.1.37 says that unprotected wires must be routed over surfaces made of combustible materials, either through something fireproof, or with a 10mm gap. The definition of a protected wire is that it is a wire that, in addition to insulation, has a electrical insulation metal or other shell to protect against mechanical damage. If you do wiring on a VVGNG, then its general external insulation is considered a fur shell. damage? Or VVGNG is not protected by definition, and then they cannot do wiring on brackets. I'm kind of confused because... half of the articles on the Internet on this topic do not consider this option at all open wiring on staples.

2. What is the correct name for sleeves for passing through walls? Cable penetrations? You need to Google it and buy it. Or do they not sell them and you have to cut the pipes yourself and provide them with plastic tips to prevent damage to the wire by the edge of the pipe? In this case, what tags should you use to search for these tips on the Internet for purchase? Or do we have to do them again ourselves?

3. Sockets, switches, etc. must be installed on the met. grounds. Do PUEs somehow regulate their thickness?

4. Is it allowed to lay cables, install switches and sockets on the external walls of the house (with inside, of course).

5. Is it possible to use the same penetration and the same boxes for power cables and weak currents?

Thanks in advance!

Gregory:

05/05/2016 at 18:20

1. Turn on the logic.. the cable (CABLE, not WIRE) must be INSULATED from the flammable surface either by a layer of air or by a blanket of plaster. This means that you need: either non-flammable insulators that will push the cable away at a distance of at least 10 mm, or a layer of plaster at least 10 mm. What other staples, really.. that will press your cable to the tree? So that it burns better?) forget.

2. Buy a 3/4 STEEL pipe from Leroy. Saw off so that the pipe protrudes in both directions above the surface by 2 cm. Buy an electrical pipe with a diameter of 25 mm. It fits neatly inside the 3/4. Cut it off a cm more than the metal pipe. Wrap the ends with electrical tape so that it doesn’t fall out of the metal pipe. That’s it, you’re done.

3. Does not regulate, IMHO. I lay the cable in a tray 0.7 mm thick. Enough for burning. Take 0.7 mm and ground it. Double control.

If you don’t understand, write me an email and I’ll send you a photo.

Grigory.

4. The question is not clear. Expand the topic.

5. The weak point can be different. It’s better not to take risks and throw the weak point separately (against mice) in a PVC metal hose.

I recently installed wiring in sheds, I also did it with staples because I’ve read a lot of different articles about staples, VVGngP/VVGng 2*1.5 2*2.5

I’ll soon be putting it into corrugation and then consulted with electricians/firemen. The general conclusion is that you can use the brackets for yourself, but if the firefighters come to check, they will screw you up and can shut down the house until it is fixed. and again, it’s your own house..

I read the PUE later. but even then, as a non-specialist, some subtleties require consultation.

Regarding the pipe in Leroy, it’s better to go to plumbing stores. The imported pipe is cheaper in Leroy, currently costs almost 800 rubles for two meters

in a plumbing store 260 rubles for two meters Russian.

Author of the site, please answer the following earlier questions asked(and it’s better to duplicate the answer in the article itself):

1. Should the electrical panel in which the machines are located also be metal, not plastic? Or can it be plastic, but must there be a metal base for the shield?

2. Are there any ready-made sleeves available for the passage of walls? Different diameters and lengths? Or you need to take simple gas pipes and make them yourself. And wouldn’t it be more correct to make the length of the pipe-sleeve such that there would be about 10 mm protruding on each side of the wall. Then cut threads at the ends and tighten this sleeve on both sides with thin nuts and washers?

And then, where can I get the bushings that are inserted into the pipe on both sides so as not to damage the cable? If I do it myself again, can you advise what to use and how to use it?

3. How to choose the correct cable channel size for a certain number of outgoing lines? (you can even make a separate article about this, since there are many combinations, at least for cables with a cross-section of 1.5 and 2.5 mm and different numbers of them in different, most popular combinations)

I wonder if anyone still sells these wiring rollers?

That's how they sell it. And not just videos. It's called retro style. And switches - like they make antique bags, sockets and other small things...

And moreover in lately retro wiring is in great demand.

Dear admin.

Heap important issues remained unanswered, such as the material of the shield in a wooden house. Will we wait for them?

For the shield better material than metal, you can’t find it. And you need to install the electrical panel on a non-flammable plate - thick metal, GVLV sheet, etc.

Please tell me, I started changing the wiring in a wooden house. IN cable channel laid the VVGngLS 3x6 flat cable. Then I saw that this cable is round and, apparently, with filler. The question arises: is it allowed to use a flat cable? Can I replace it with a round one?

Don't change anything. Their operational properties are the same. The filler just gives the round VVG a round shape.

Specifically regarding the question, there is no mistake, the PUE does not regulate whether the cable is flat or round. If it is really VVgNgLs, then everything is in order. The flat one closes more conveniently into the cable channel, the round one has a large bending radius.

The second point is, what device powers this cable and what rating is the circuit breaker selected to protect this line? This is too large a cross-section for sockets. More like an input cable for the main panel.

Thanks everyone for your help.

The cable runs from the box with the meter to the distribution board. The machine is set at 32A.

Any owner of a house or apartment wants the electrical wiring in his home to be of high quality and reliable. If experience and knowledge allow, it is quite possible to do the wiring correctly with your own hands, both in a panel and wooden house.

At first glance, if you install electrical wiring in a wooden house in accordance with the requirements of SNiP, PEU, there will be no problems. However, laying fireproof electrical wiring in a wooden house is actually doable, and you can choose which wiring to use.

Why should the VVGng cable be laid along the wall in a corrugated or cable duct? After all, VVGng is made of non-flammable insulation, and corrugated pipes and cable channels are made of ordinary plastic. Or do you need to use metal corrugated pipes and cable ducts? Something I haven’t seen at anyone’s dacha like this...

Why can’t I move in, from the photo you can see that the cable is all in the cable channel ON wooden wall, without The cable channel even comes into contact with the wall, but in my house it runs along the wall in corrugation with brackets and the wall itself is sewn in plaster and now I don’t see the difference between the wiring I have done and the one shown here as external. What should I do? change everything or leave it?

Alexey, if the cable is run along a wooden wall, and then the wall is covered with plasterboard along the profile, then this is hidden wiring, not open.

SP 256.1325800.2016 “Electrical wiring in cavities above impenetrable suspended ceilings and inside prefabricated partitions are considered as hidden.” If there is something flammable inside the partition, such as wood, this is flammability class G4, with all the consequences of laying cables in metal pipes..

But according to PUE 7, the cable can be laid in the plaster strip.

Compromise on safety - You first had to sew 9.5mm strips of plasterboard, making a non-flammable gasket between the cable and the wooden surface, cover it with a second strip of the same on top, enclosing the cable in a non-flammable sheath, and then cover the wall along the profile with plasterboard..

Something is not clear in a wooden house, is it possible that installation methods that cannot be used with hidden wiring are allowed with open wiring? What's the point in all this? At first I thought that the authors of the articles were different.

Good afternoon. Everywhere it is written that the passage through the wall must be made of a metal pipe, but when the cable is heated, everything is transferred to the combustible surface, especially if the pipe is thin. Why can't you use a plastic non-flammable pipe? What is it inferior to? The following question is also interesting: is it possible to do the wiring in the box if its dimensions allow it?

SP 31-105-2002 clause 13.5 I would very much like to hear your opinion on this system of regulatory documents in construction.

good afternoon! I have this problem: I have a short circuit on the switch, when you turn it off, the switch sparks and the meter makes a crackling sound!

And what do you turn off that sparks, an ordinary light bulb? In general, the switch cannot but short-circuit, this is its direct job - to close the contacts in the power circuit of the meter/fuse (machine)/switch/lamp/meter.

How nice it is to come home in the evening and see bright light in the windows. It’s immediately clear that you are expected and missed here. But just think about how dangerous poorly made electrical wiring in a wooden house can be. According to fire department statistics, 60% of fires occur due to a short circuit or fire in the wiring. And the reason for everything is poor-quality electrical wiring in a wooden house.

In addition to all this, poorly done electrical work in the house can even kill your family members. It is imperative to approach this problem wisely and choose only the highest quality materials.

The entire system is laid according to the PUE “Rules for the construction of electrical installations”. To figure out how to do this correctly and according to the relevant standards, you need to have at least a technical education. Let's try to understand this system more simply.

According to modern rules fire safety electrical wiring can be hidden or open. Depending on its location, it can be internal or external. By power transmission lines: single-phase and two-phase. In our article we will talk about a single-phase system. Since this is the kind of wiring that is used in everyday life for wooden houses.

![]() The cable is carried from the main power line to the house by air. This cable should only be laid by specialists, as doing it yourself is simply dangerous. The most important thing that the owner should pay attention to when carrying out external wiring is the area from the outer wall to distribution panel. This section of the wire will not be protected by anything and will pass through a fire-hazardous structure. This is where it’s worth thinking about additional security measures.

The cable is carried from the main power line to the house by air. This cable should only be laid by specialists, as doing it yourself is simply dangerous. The most important thing that the owner should pay attention to when carrying out external wiring is the area from the outer wall to distribution panel. This section of the wire will not be protected by anything and will pass through a fire-hazardous structure. This is where it’s worth thinking about additional security measures.

You can secure this area with:

- Output of the table pipe. When installing such a structure, the cable is hidden in a steel pipe. This design is easy to make if the distance from the input through the wall is not very large. According to fire safety regulations, this distance should not exceed 3 m. But if the cable runs in an area with many corners, then pulling it into a pipe with turns will be quite difficult.

- Installation of additional protection at the input. On external wall install two-pole circuit breaker. When installed, this device is placed in a special moisture- and dust-proof block. In case of overload, the machine will be triggered and the input wiring will be protected from overload. This system is quite convenient, since you can install the input shield at a large distance. This will make it possible to route the cable along the path that suits the owner of the house. But even with this design, a cable through the input is still needed.

- Installing protection directly on the pole from which the voltage comes. It is convenient to install such a system during connection. During this method, the electrical inspector can monitor the meter without entering the house. The electrical circuit breaker will be installed on the line itself on the pole. Such a system can only be done by professionals, and it is not the responsibility of electricians during installation, so you will have to pay for such work separately.

Internal wiring in a wooden house

All internal wiring starts from the panel. It is into the panel that the electrical wire comes after insertion. The switchboard must also be installed by your electrical company. Otherwise, the installation may not be of high quality, and you will not be insured against electrical loss or fire. And this is already a matter of life.

All internal wiring starts from the panel. It is into the panel that the electrical wire comes after insertion. The switchboard must also be installed by your electrical company. Otherwise, the installation may not be of high quality, and you will not be insured against electrical loss or fire. And this is already a matter of life.

The main internal wiring is already carried out from the shield. It can be open and hidden. Let's look at each of these schemes in more detail.

Open electrical wiring in a wooden house

Open electrical wiring speaks volumes about its location by its name. Such wiring is carried out directly along the walls of the house. It may differ from the method of insulating wires from walls by:

- Simple laying of wire in double or triple insulation.

- Insulation using corrugated non-flammable pipes.

- Insulation using cable ducts.

Simple gasket

For such a wiring system, a rigid single-wire cable with insulation is usually used. It is best if this insulation is double or triple. For example, these are VVG or NYM cables; these cables have non-flammable insulation, which is most suitable for. These wires are attached to the wall using special iron brackets. If the area exceeds 7 square, then the cable is pulled in pairs. When such a system uses standard insulated material, a gasket made of non-combustible materials is installed under the cable. For example, it could be asbestos or metal tape. When laying a cable on it, such protection should protrude from both sides by at least 10 mm. Previously, such wiring was mounted on ceramic rollers, but now the use of such insulation is prohibited.

For such a wiring system, a rigid single-wire cable with insulation is usually used. It is best if this insulation is double or triple. For example, these are VVG or NYM cables; these cables have non-flammable insulation, which is most suitable for. These wires are attached to the wall using special iron brackets. If the area exceeds 7 square, then the cable is pulled in pairs. When such a system uses standard insulated material, a gasket made of non-combustible materials is installed under the cable. For example, it could be asbestos or metal tape. When laying a cable on it, such protection should protrude from both sides by at least 10 mm. Previously, such wiring was mounted on ceramic rollers, but now the use of such insulation is prohibited.

This type of electrical wiring today is considered the most inexpensive, especially if you have to lay more than one cable in parallel.

Insulation using corrugated pipes

The second method of open wiring is a corrugated pipe. The cable is passed through special corrugated pipes, which are good protective device from fire and combustion. Several wires can be inserted into such a pipe at the same time. Such pipes should be secured to the walls using special clips.

The second method of open wiring is a corrugated pipe. The cable is passed through special corrugated pipes, which are good protective device from fire and combustion. Several wires can be inserted into such a pipe at the same time. Such pipes should be secured to the walls using special clips. The main advantage here is that such wires already look better on the walls, but are not aesthetically pleasing enough. This type of wiring is used in utility rooms, for example in a boiler room. The disadvantage of such wiring is that if you need to replace a piece of wire or re-tighten the system, you will have to remove all the pieces in the pipes entirely with a common structure.

Wiring using cable channels

Cable channels are special boxes that are attached to the wall using self-tapping screws. The cable channel has a cover on top that simply snaps into place.

Cable channels are special boxes that are attached to the wall using self-tapping screws. The cable channel has a cover on top that simply snaps into place.

Installing these channels throughout your home is not that difficult. But this requires some skill and a pre-thought-out system to make the cable channels consistent with the entire design of the house.

The advantage of such a system is that it is easy to dismantle such wires later and change their location, or add additional sockets.

Sold with these boxes additional materials, which we will talk about in more detail later.

In a wooden house, it is best to install such wiring after the wood has completely dried. Otherwise, there may be gaps between the cable channel and the decorative trim.

This method of wiring is not the cheapest, but it looks aesthetically pleasing.

Hidden method of electrical wiring in a wooden house

Hidden wiring, this is a system of electrical wires that are hidden in all the voids of walls, ceilings, and floors.

Let's say right away that hidden wiring for wooden houses is not recommended. This happens due to the same fire safety. But today this has already been decided. Special steel pipes are produced that bend well and the wiring is hidden in them before hiding it throughout the building. But anyway, firefighters can fine you if they see this type of wiring in your wooden house.

Of course, many companies still do this wiring because the customer wants it. But living in a wooden house that could catch fire at any moment is extremely reckless. Of course, many people want the wiring to be hidden and the appearance of the walls to be aesthetically pleasing, but if you take a good look at modern decorative items for external electrical wiring, then I assure you that you will find a very original and suitable solution for you.

One of the wiring methods can be seen in the video:

Decorative elements for exposed electrical wiring

Today you can find a very wide variety of cable channels for wooden walls. There are cable channels in colors that completely harmonize with the wood. Such channels can be easily placed on the walls, and they will not be noticeable.

Today you can find a very wide variety of cable channels for wooden walls. There are cable channels in colors that completely harmonize with the wood. Such channels can be easily placed on the walls, and they will not be noticeable.

For such wiring they sell corners and special color-matched sockets and switches. You can choose cable channels and traditional white and brown colors. Then just make them part of the interior. This needs to be thought out in advance.

The next decorative element that everyone has today hardware store, this is a plinth with a cable channel. The wires are hidden inside such a plinth and covered on top with a decorative lid with locks. Externally, this plinth will not be any different from the others.

The next decorative element that everyone has today hardware store, this is a plinth with a cable channel. The wires are hidden inside such a plinth and covered on top with a decorative lid with locks. Externally, this plinth will not be any different from the others.

Another decorative element, these are the newest wires on insulators using a special cable consisting of a stranded copper core, PVC insulation, PVC sheath and decorative braid (silk impregnated with non-flammable substances).

Such a cable must be mounted at a distance of more than 1 cm from the walls, on special decorative ceramic barrels. This modern version, for lovers retro style. Such wires look beautiful on wooden walls that do not have additional coating.

Calculate required quantity Electrical wiring is not difficult; to do this, draw a diagram of your future electrical system and measure the walls. But this is not the main thing, the main thing is to choose a cable of the required and suitable thickness and carry out the wiring in compliance with all the rules and recommendations for residential buildings.

Calculate required quantity Electrical wiring is not difficult; to do this, draw a diagram of your future electrical system and measure the walls. But this is not the main thing, the main thing is to choose a cable of the required and suitable thickness and carry out the wiring in compliance with all the rules and recommendations for residential buildings.

The electrical wiring of a residential building must have a voltage of 220 or 380. The entire internal circuit must be separated by neutral protective and neutral working conductors. When calculating electrical wiring, calculating the load, the design load of electrical receivers should be taken at least:

- 5.5 kW - for a home without electric stoves;

- 8.8 kW - for a house with electric stoves.

if the living area of your house exceeds 60 square meters, design load should be increased by 1% for each additional sq.m.

The cross-section of the wires is calculated based on the connected power. Electrical wiring must be calculated using the formula P = Rust x Ks. Where is Rust? total power included receivers, Kc – demand coefficient. The choice of wire for your electrical wiring depends on this indicator.

|

Wire thickness for electrical wiring |

Copper wire |

Aluminum wire |

||

|

Power kW |

Power, kW |

|||

After the diameter of the electrical wiring has been calculated, you need to completely draw the entire circuit throughout the house, including sockets and switches.

First, we assemble the entire internal circuit and mount the switches and already marked sockets.

Sockets on wooden walls are placed externally, on a non-combustible base. It is necessary to place a non-combustible material underneath. They are screwed directly to the wall with screws. Only after collecting the entire internal circuit and visually checking it for correctness can you connect external wiring. But do not forget that working with electricity requires additional skills, and without these, it is best to turn to specialists.

After laying the electrical wiring, you need to take measurements:

- Visual inspection of electrical wiring and electrical equipment

- Grounding calculation.

- Calculation of insulation resistance.

- Calculation of the resistance of the phase-zero circuit.

- Measurements and testing of automatic differential current controlled circuit breakers (RCDs)

- Testing (loading) of circuit breakers

- Measuring the resistance of grounding devices

In most cases, a short circuit in the electrical wiring occurs due to the stupidity and stinginess of the owner of the premises, since he categorically does not want to carry out the electrical installation in compliance with all norms and requirements. The owner does not want to conduct periodic inspections and electrical measurements of his electrical equipment and power supply, since these are additional unaccounted expenses for the operation of electrical equipment. What causes short circuits in electrical wiring? The main cause of short circuits is wear and tear of the insulation of conductors in electrical wiring. This occurs due to mechanical damage to the electrical wiring insulation or excessive load on the wires and cables. How to avoid these troubles? What should be done to prevent or minimize the risk of short circuits in electrical wiring? In this article we will try to convey to the reader how to correctly install internal hidden electrical wiring in a wooden house.

Articles of the series

- Electrical installation of input into a wooden house with VVGng cable in the ground. Continuation

Most home-grown electricians try to quickly spread hidden electrical wiring around wooden bases and cover up the traces of their crimes in the voids of combustible structures, that is, behind the false ceiling, under the cladding of walls and in combustible floors. Whether out of ignorance or intentionally, some people do not shun these violations. electrical installation organizations. The grossest violation of the rules for electrical installations is the hidden laying of cables along wooden bases (walls, floors, ceilings) in a corrugated pipe, metal hose, or plastic box. There are such “Kulibins” who carry out electrical installation of hidden electrical wiring without any protection at all, motivating their actions by the fact that his great-grandfather did this and lived to be 100 years old.

Why is it impossible to carry out electrical installation of hidden electrical wiring in wooden houses using corrugated PVC pipe, metal hose, or plastic duct? Let's look at several situations that may arise when operating electrical wiring. By laying hidden electrical wiring using corrugated PVC pipe or PVC duct in the voids of wooden walls, floors and ceilings, you will not be able to protect the cable from rodents, who love to sharpen their sharp teeth on parts of your electrical supply.

Rats and mice easily chew through PVC pipes and PVC ducts and expose wire strands, which subsequently short out, resulting in a short circuit in hidden electrical wiring. A lot of wood dust accumulates in the voids of the floors and the slightest spark leads to a fire wooden house, but the worst thing is that it is very difficult to immediately determine the location of the fire and put it out, since the entire process of the fire consuming your goods occurs behind the sheathed walls and ceilings. You can fill all the walls with water and foam, but the result will be zero, it will be impossible to put it out until the entire structure burns down.

But not only rodents pose a threat to hidden electrical wiring laid on wooden bases in the voids of combustible floors using PVC pipes and PVC plastic boxes. While laying the cable, the electrician may slightly damage the insulation of the conductors, and during electrical measurements, this damage may not be detected. But during operation, when all the necessary electrical equipment is connected, the electrical wiring operates in the maximum permissible load mode. Such operation can weaken the insulation of the cable or wire, as the conductors heat up, causing a short circuit in the electrical wiring. Since the walls plastic pipes and PVC boxes are not able to withstand a short circuit in the electrical wiring without burning out the walls, therefore, such a short circuit in the hidden electrical wiring will inevitably lead to a fire.

There is an opinion that the installation of hidden electrical wiring on wooden foundations using a metal pipe does not pose any danger and reliably ensures fire safety in a wooden house. But such misconception can be costly for those who ignore necessary standards and requirements.

A metal hose, like a corrugated pipe, protects electrical wiring from minor mechanical damage, but cannot serve as protection against fires due to short circuits in electrical wiring, since it does not have localization ability.

The question may arise: What kind of ability is this that does not allow hamster electricians to perform hidden electrical installations without special costs and effort? We answer: Localization ability is the ability of a fireproof material (metal pipe, steel box) in which a cable is laid to withstand a short circuit in a cable or wire, without burning out the walls of the fireproof material.

This means that if there is a short circuit in hidden electrical wiring, the walls of the metal pipe burn out, which inevitably leads to a fire. Further developments can be found in the daily reports of the Ministry of Emergency Situations.

Articles of the series“The whole truth about electrical installation work in a wooden house”:

- Electrical installation of input into a wooden house with VVGng cable in the ground

- Electrical installation of input into a wooden house with VVGng cable in the ground. Continuation

- Electrical installation of internal open wiring in a wooden house

- Electrical installation of internal hidden electrical wiring in a wooden house. Continuation

- How to separate a PEN conductor in an electrical installation (ASU, main switchboard). Start

- How to separate a PEN conductor in an electrical installation (ASU, main switchboard). Continuation

PUE-6

2.1.4

Electrical wiring is divided into the following types:

1. Open wiring, laid on the surface of walls, ceilings, trusses and other building elements buildings and structures, on supports, etc.

For open electrical wiring, the following methods of laying wires and cables are used: directly on the surface of walls, ceilings, etc., on strings, cables, rollers, insulators, in pipes, boxes, flexible metal sleeves, on trays, in electrical skirting boards and platbands, free suspension, etc.

Open electrical wiring can be stationary, mobile and portable.

2. — laid inside structural elements buildings and structures (in walls, floors, foundations, ceilings), as well as on floors in floor preparation, directly under a removable floor, etc.

For hidden electrical wiring, the following methods of laying wires and cables are used: in pipes, flexible metal hoses, boxes, closed channels and voids building structures, in plastered furrows, under plaster, as well as embedded in building structures during their manufacture.

2.1.32

When choosing the type of electrical wiring and the method of laying wires and cables, electrical safety and fire safety requirements must be taken into account.

2.1.37

When laying open protected wires (cables) with shells made of combustible materials and unprotected wires, the clear distance from the wire (cable) to the surface of bases, structures, parts made of combustible materials must be at least 10 mm. If it is impossible to ensure the specified distance, the wire (cable) should be separated from the surface by a layer of fireproof material protruding from each side of the wire (cable) by at least 10 mm.

2.1.38

When hidden laying of protected wires (cables) with shells made of combustible materials and unprotected wires in closed niches, in the voids of building structures (for example, between the wall and the cladding), in furrows, etc. with the presence of combustible structures, it is necessary to protect wires and cables with a continuous layer of fireproof material on all sides.

2.1.39

When laying pipes and ducts made of non-combustible materials openly on non-combustible and non-combustible bases and structures, the clear distance from the pipe (duct) to the surface of structures and parts made of combustible materials must be at least 100 mm. If it is impossible to ensure the specified distance, the pipe (box) should be separated on all sides from these surfaces by a continuous layer of fireproof material (plaster, alabaster, cement mortar, concrete, etc.) with a thickness of at least 10 mm.

2.1.40

When concealed laying of pipes and ducts made of non-combustible materials in closed niches, in the voids of building structures (for example, between a wall and the cladding), in furrows, etc., pipes and ducts should be separated on all sides from the surfaces of structures, parts made of combustible materials a layer of fireproof material with a thickness of at least 10 mm.

2.1.41

When crossing short sections of electrical wiring with elements of building structures made of combustible materials, these sections must be made in compliance with the requirements of 2.1.36 - 2.1.40.

Table 2.1.3

Selection of types of electrical wiring and methods of laying wires and cables according to fire safety conditions

Type of electrical wiring and method of laying on foundations and structures made of combustible materials

Hidden electrical wiring

1. With a lining of fireproof materials (1) and subsequent plastering or protection on all sides with a continuous layer of other fireproof materials.

Unprotected wires; protected wires and cables sheathed in combustible materials.

2. Lined with fireproof materials(1).

Protected wires and cables sheathed in flame retardant materials.

3. In pipes and ducts made of fire-resistant materials - with lining under the pipes and ducts of non-combustible materials (1) and subsequent plastering (2).

Unprotected wires and cables sheathed in combustible, non-combustible and non-combustible materials.

_____________

1 A lining made of fireproof materials must protrude from each side of the wire, cable, pipe or box by at least 10 mm.

2 Plastering of the pipe is carried out with a continuous layer of plaster, alabaster, etc. thickness of at least 10 mm above the pipe.

PUE-7

7.1.38

Electrical networks laid behind non-passable suspended ceilings and in partitions are considered as hidden electrical wiring and should be carried out; behind ceilings and in the voids of partitions made of flammable materials in metal pipes with localization ability, and in metal blind boxes; behind ceilings and in partitions made of non-combustible materials* - in pipes and ducts made of non-flammable materials, as well as flame retardant cables. In this case, it must be possible to replace wires and cables.

________________

* Suspended ceilings made of non-combustible materials mean those ceilings that are made of non-combustible materials, while other building structures located above suspended ceilings, including interfloor ceilings, are also made of non-combustible materials.

Read also:

One of the important decisions in constructing a power supply circuit in a wooden house is the choice of cable laying method and installation of electrical equipment (lamps, sockets, switches). This matter must be approached with full responsibility...

Beginning of the article “Installation of internal hidden electrical wiring in a wooden house. Start". When choosing a method for installing hidden electrical wiring in a wooden house, the first step is to take into account fire safety and electrical safety requirements. Design and cost of electrical installation...

Electricity supply country houses, garden partnerships and houses in the village, in the overwhelming majority, is carried out by air lines power transmission This means that the consumer receives electricity through the “TN-C” grounding system, which...

Beginning of the article “How to separate a PEN conductor in an electrical installation (ASU, main switchboard)“. Having removed the external insulation of the cable, lay the phase conductors to the switch or protection device with a reserve for cutting the wire cores and the possibility of re-use...

Andrey Hello! There is a wooden timber house. Electrical wiring is laid openly in PVC cable ducts. I want to cover the inside of the house with clapboard that will cover the cable channels. Will this wiring already be considered hidden? And for her to become again...

22 Comment(s) on “The whole truth about electrical installation work in a wooden house in accordance with PUE and PTEEP. Electrical installation of internal hidden electrical wiring in a wooden house. Start"

-

Hello, Nikolay!

We don't throw mud at anyone. In the article “The whole truth about electrical installation work in a wooden house in accordance with PUE and PTEEP. Electrical installation of internal hidden electrical wiring in a wooden house. Home » we described what violations electricians commit when performing work. If you think that we are misleading readers, then try to justify your method of electrical installation work on combustible bases. If you do not have such regulatory documents, and you agree with our arguments, then we advise you to correct your attitude towards work and carry out electrical installations in accordance with the rules for electrical installations.

Sincerely, the team of the ElektroAS company. -

Hello, Boris!

Thank you for your kind words addressed to us.

Hello, Alexey!

A wooden lattice covered on both sides with plasterboard is considered as a building structure made of combustible materials. Hidden electrical wiring in such structures must be carried out in accordance with the PUE, clause 7.1.38, in metal pipes with localization ability, and in metal blind boxes. It is also possible to carry out hidden electrical wiring in PVC-ng pipes (corrugated pipe) and PVC-ng boxes (non-flammable), but only with a lining on all sides and along the entire length of fireproof material (plaster, alabaster, cement mortar, concrete etc.).Hello, Vladimir!

We hasten to disappoint you, but the links we provided to regulatory documents apply to all residential and public buildings. We advise you to carefully read them and strictly comply with the current requirements.CODE OF RULES FOR DESIGN AND CONSTRUCTION (SP 31-110-2003)

DESIGN AND INSTALLATION OF ELECTRICAL INSTALLATIONS FOR RESIDENTIAL AND PUBLIC BUILDINGS

1 AREA OF APPLICATION

This Code of Rules establishes the rules for the design and installation of electrical installations of newly built and reconstructed residential and public buildings in cities and rural areas.

14.3

Internal electrical networks must be flame retardant and made with cables and wires with copper conductors in accordance with the requirements of 2.1 and 7.1 of the PUE.RULES FOR ELECTRICAL INSTALLATIONS (PUE)

1.1.1

Rules for the construction of electrical installations (PUE) apply to newly constructed and reconstructed electrical installations of permanent and AC voltage up to 750 kV, including special electrical installations, discussed in section. 7 of these Rules.

Hello, Vladimir!

Hello, Gregory!

The photographs show hidden electrical wiring behind impenetrable suspended ceilings and in the voids of building structures (between the wall and the cladding) made of flammable materials at the stage of laying group cable lines before cladding the walls and ceilings.Hello, Denis!

Your question has been redirected to . You can register on the forum and discuss "" in more detail with forum participants.

Hello. Good material about electrical installation work in wooden houses, everything is clear and understandable.

Out of curiosity, I went to the site indicated in the photo that you criticize and did not find it. But there are other photos on the page that show that the electrical wiring was not done correctly. Not only is it laid with a fire-propagating cable, but it also goes into a wooden wall into a hole without a pipe. Or am I wrong?

Hello!

How is it positioned? frame construction— a wooden lattice covered on both sides with plasterboard? How should the cable be routed in this case? Thank you.

Tell me please. There are 3 people in the apartment storey building on the 1st floor from electrical panel hidden wiring (VVG or VVGng) in PVC corrugation in brick wall goes down under the floor (wooden floor on brick posts). Further, under the floor, it comes out of the wall and in a corrugated PVC, suspended from the joists, stretched to the walls and brought out at the walls back into the rooms to the sockets and branch boxes. There is access to the underground, but the height of the “ceiling” there is about 70-80 cm. Have the norms been violated?

Hello!

I want to ask one more question regarding the photographs presented as illustrations of the violation. So, on them we see wiring laid along a wooden structure in a corrugated pipe (an open protected installation). The corrugated pipe is attached to the wall using corrugated pipe clips. Most of the clips produced have a base of 1 cm, so that the corrugation does not fit flush against the wall, but hangs at some distance from it.

At the same time, the 7th edition of the PUE teaches us:

clause 2.1.37. When laying open protected wires (cables) with shells made of combustible materials and unprotected wires, the clear distance from the wire (cable) to the surface of bases, structures, parts made of combustible materials must be at least 10 mm.

and only then in this paragraph it is indicated about laying non-combustible materials under the cable, if it is impossible to maintain these 10 mm, as rightly stated in the second part of your article.

It turns out that the use of clips with such a base allows you to maintain the normalized PUE distance of 10 mm to the combustible wall, and the installation is not so wrong?

Good afternoon, I read your article and learned a lot of new things.

I have such a case, the contractors laid the cable in the ceiling space in a corrugated PVC pipe, it seems like everything is fine, but they secured it with zip ties corrugated pipe to the traverses on which serves to suspend the ceiling. The question is where in regulatory documentation Is it stated that pipes can be attached, for example, only to walls and ceilings, and are prohibited to traverses of other systems?

Despite a number of advantages inherent in wooden houses, they also have a very serious drawback - the ability to quickly ignite and burn. Moreover, a fire can start not only due to improper operation of the stove and other heating devices, but also due to improper installation of electrical wiring, neglect when laying the rules of the Electrical Installation Code.

For the correct design, calculations and safe installation of electrical wiring, a technical document has been developed - “Rules for the construction of electrical installations” (abbreviated as PUE).

How not to install wiring

You should not rely too much on the quality of cable insulation, because many processes take place in cable channel designs that cannot be foreseen in advance:

- temperature changes;

- dust accumulation;

- humidity fluctuations;

- microdeformations of insulation.

With increased loads on the network, there is a high probability of breakdown between wires stretched in parallel and, in the absence of their fencing from flammable bases, a fire is inevitable.

According to clause 7.1.38 of the PUE, hidden electrical wiring in log house should not be laid on wooden structures; laying wires in corrugated or plastic boxes is prohibited.

From elevated temperature When hidden wiring burns, even corrugated hoses are not able to protect, since their walls do not have the proper thickness and are not designed to withstand the impact high temperatures. Home useful characteristic, inherent in the channels, is their ability to withstand a short circuit without burning out in the period of time required for the natural attenuation of the arc.

This property is fully inherent only in pipes and ducts made of steel and recommended for installing hidden wiring in wooden buildings.

Correct wiring

There are many ways to install hidden wiring in wooden houses, but only some can be considered correct and appropriate for all PUE requirements. Both in the design and installation process, first of all, you need to follow fire safety requirements.

Hidden electrical wiring in a house made of rounded logs is installed in special channels made of non-flammable materials, which localize a possible fire within themselves. At the same time, the aesthetic qualities and ideas of the designer, the cost of materials and production of work must be moved to a secondary level.

The best material for laying wires hidden in voids wooden structures ceilings and walls, steel boxes and metal pipes are considered. When using non-flammable PVC materials (installation boxes or corrugated pipes), on each side it is necessary to install fireproof and non-heat-conducting gaskets from:

- concrete;

- alabaster;

- cement plaster.

The thickness of the gasket is calculated based on the required wiring characteristics.

The most reliable method for making wiring installation that complies with the recommendations of the PUE is considered to be laying it in steel or copper pipes and ducts. Copper pipes are easily bent without the use of any special devices and tools, which is important if it is necessary to install branched electrical wiring.

Using steel pipes is a little more difficult and requires highly skilled workers, especially when replacing wiring in small sections. The sharpened edges of the boxes can deform the insulation of the wires, so cutting them must be done only with a specialized tool.

Route selection

The selection and subsequent marking of the wiring line should be carried out strictly in accordance with the requirements of the PUE. The number of turns and bends must be kept to a minimum, and at points where, due to architectural features building, laying the route is difficult; installation of junction boxes is necessary.

When installing boxes, it is forbidden to cover them under any decorative elements, making it difficult open access for maintenance during operation, inspection or measurement.

Pipes for electrical wiring are buried so as not to disturb the strength and load-bearing properties of the structural elements of the building. The cross-section of the pipes and the thickness of their walls are selected based on the characteristics of the cable. The wire placed in the pipe should occupy less than 40% of the total internal volume and stretch without problems over the entire length of the section. When laying several cables in a pipe at once, their total volume should also be less than 40% of the internal cross-section of the pipe.

Before laying the cable, it is necessary to calculate the insulation resistance in advance. This procedure is carried out in order to determine the compliance of the wire with the requirements of the technical specifications, to identify possible insulation deformations during transportation and storage, and to perform preparatory work.

Wire selection

After developing the diagram and marking of each node, you should decide on the brand of wire used directly for installation. IN wooden buildings It is recommended to use cables with the following markings:

- VVGng (A) or VVGng-P (A);

- VVGngLS, VVGng-PLS;

Solid copper wire (containing up to five cores) marked VVGng (A) or VVGng-P (A) is covered with double insulation. Internal insulation made of PVC, with each core painted different color, is insulated separately, which greatly facilitates the installation of sockets, switches, and lighting devices. Outside, the cable is covered with insulation made of flexible composite plastic, which allows it to be used in temperature range from +50 to -50 °C.

The characteristics of wires of the VVGng LS, VVGng-P LS brands are fully consistent with the previous brand, the difference is the absence of emission when heated harmful substances(chlorine-hydrogen).

The NYM cable is manufactured according to GOST 22483 and has three insulating layers. The wire strands are first insulated individually, then the bundle of strands is placed in composite material, and then assembled into a non-flammable PVC shell.

Location of sockets and switches

At the points of future installation of switches and sockets, using special equipment, sockets should be drilled into which metal boxes will subsequently be mounted. Such boxes, as well as junction boxes, are mounted using appropriate technology, which involves the production of a number of compulsory work, as a result of which a high-quality connection between the box and the pipe and reliable contacts between all elements should be ensured.

The contact is also important for providing grounding. If continuity of the circuit is ensured during the installation of electrical wiring, then grounding can only be performed in the distribution panel.

Of the several methods of attaching boxes to pipes, welding and soldering are the most reliable. These methods ensure maximum contact reliability, full protection from corrosion and resistance to mechanical loads.

If you use wires to connect the socket copper pipes, then their open edges, brought into the box, must be flared. If steel pipes are installed, then the connection to the box is made using nuts, for which threads are cut into the pipe heads. In order to ensure maximum screwing tightness, the nuts are cleaned of traces of corrosion and securely fixed.

If you use wires to connect the socket copper pipes, then their open edges, brought into the box, must be flared. If steel pipes are installed, then the connection to the box is made using nuts, for which threads are cut into the pipe heads. In order to ensure maximum screwing tightness, the nuts are cleaned of traces of corrosion and securely fixed.