Electrical cable and wire are an integral part of absolutely any power supply system and, like any electrical equipment, they require constant attention. Electrical wiring and cable lines must be subjected to insulation resistance measurement immediately after and during operation. During manufacture, during transportation to warehouses and facilities, the cable is constantly subjected to mechanical stress.

Drums and coils with cable and wire are rolled, dragged along the ground, thrown from place to place. In addition, they lie in the open air and scorch under the hot sun or freeze at 40 degrees below zero. Naturally, under the influence of precipitation, high and low temperatures insulation begins to age prematurely. Unfortunately, most electricians ignore these facts and carry out cable wiring without prior verification. In addition, installers very often violate the installation technology and lay the cable with gross violations. Therefore, only measuring the insulation resistance can guarantee the quality of the insulation of conductors walled up in walls, floors and ceilings.

During operation, cable lines and electrical wiring also have a hard time. Very often, when installing powerful modern equipment and technology that consumes a large number of electricity, I do not take into account the fact that this electrical installation is simply not designed for such power. As a result, the conductors overheat during operation, their insulation wears out and ages quickly, and circuit breakers constantly disconnect the load. Some enterprising people solve the last problem by installing a protection device with an overestimated rating, thereby rendering the conductor insulation unusable.

Since unprotected wires with worn insulation can at one point cause a fire. Periodic measurement of insulation resistance allows you to identify all these problems and eliminate them in a timely manner. Otherwise, they will, at a minimum, lead to a leakage of electricity, and, at a maximum, to a fire.

Measurement of insulation resistance begins with a visual inspection. When examining cable lines and electrical wiring, electrical laboratory specialists first of all check their outer insulation for visible damage and defects. Please note that in the places of cable bends, passages through walls, places of inputs into switchboards, it must be protected from mechanical damage. Special attention during visual inspection, be given to the melted ends of the insulation, since this indicates that the cable (wire) was very hot during operation. The reason for this may be a poor connection of the wires to the terminals, a malfunction or an overrated circuit breaker.

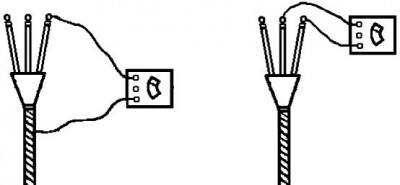

After a visual inspection, they begin to measure the insulation resistance. Tests should be carried out on a disconnected electrical installation, that is, all conductors to be tested must be in without fail de-energized, and the electrical equipment is disconnected from the network. When measuring the insulation resistance of lighting circuits, all lamps must be unscrewed from lighting fixtures and the switches are on. The measurement of insulation resistance is carried out by a device specially created for this purpose - a megohmmeter.

At the same time, it is impossible to use devices for measuring insulation resistance that have not passed annual verification. As a rule, insulation resistance is measured between phase conductors, phase and zero working conductor, phase and zero protective conductor, as well as between zero working and protective conductors. That is, the number of measurements depends on the number of wires in the line. At the same time, the least permissible value insulation resistance must be at least 0.5 MΩ.

If the measured reading is less than this value, then cable line can be divided into sections, starting from the switchboard, and the insulation resistance of each resulting section can be measured. Cable (wire) with faulty insulation is subject to immediate repair or dismantling and replacement.

Read also:

Vitaly Hello. And who can measure the insulation resistance already in the existing electrical wiring? Does the operating and maintenance personnel (electrician on duty) have the right to do this with a simple megohmmeter and will such measurements be valid? Resistance measurements...

Stanislav We built a lighting line of 23 poles. The cable between the supports is laid in the ground. Each support has a cable cut. To put the line into operation, we are forced to measure the insulation resistance ...

Elena We have a medical center in Moscow, we need to measure the insulation resistance. Eat electrical devices, which can not be turned off from the outlet, but I want to have a complete picture. How to be? Thank you. To perform a set of electrical measurements, ...

Vladimir An employee of the energy supervision ordered us to call an electrical measuring laboratory and measure the insulation resistance of the input (feeding) cable. The input cable is laid from the overhead line support to our store. To perform insulation resistance measurements, we...

The apartment wiring needs to be checked along its separate lines after the machines. But the measured insulation resistance of a separate line does not mean anything. Well, it is more than 0.5 megohm (leakage current 0.48 milliamps), so what? It is not at all clear what will happen when the wiring with cables and wires made of vinyl compound heats up to the limit operating temperature+ 70 degrees Celsius. In reality, the resistance of the lines is usually in the range of 12 - 300 megohm. For example, 2 sockets, the insulation resistance of each of them is 20 megohm, connected them in parallel to the main line, we got a resistance of 10 megohm. sockets, switches, lamps and cables to them and a line connected in series with them and it turns out total resistance in 0.5 megohm. If in this whole circuit there is a series-connected section of the cable, for example VVG, with an insulation resistance of 1 megohm at + 20 degrees Celsius, no one will notice this, and at + 70 degrees Celsius, when a nominal worker goes through this section of the cable current, and even in the summer heat, the resistance of this section will already be 500 ohms, and the leakage current will be 480 milliamps and this section will light up along with the apartment. So, it is of course necessary to measure the insulation resistance of a single line together with electrical installation products after installation is completed, but only in order to have a control value of the line insulation resistance during repeated checks, if during the control check of the line insulation resistance value it turns out that there was a decrease in the insulation resistance of the line by more than 10%, then it is necessary to carry out a complete check of all parts of the line wiring diagram separately. insulation resistance should not be less than 0.5 megohm. Therefore, when installing apartment wiring, it is necessary to check the insulation resistance of its individual sections even during the installation itself. the very time when it is still possible to redo something in the wiring, therefore it is at this time that you need to check the insulation resistance of all wires and cables. Moreover, the check should be carried out according to the standards of the manufacturer and GOST. cable and its cross section. For example, for a VVG cable at a temperature of + 20 degrees Celsius, the insulation resistance of the core per one kilometer of the length of the core with a cross section of 1.5 square millimeters is 12 megohm, and with a core cross section of 2.5 and 4 millimeters square, the core insulation resistance per kilometer of length cores -10 megohm. If the insulation resistance of the core is less than the calculated one, it is better to replace the cable immediately, that is, when known length line, it is not difficult to calculate the insulation resistance of the core, knowing its cross section. Well, after checking the insulation resistance of each section of the cable, you can solder the boxes. And after final finishing already install lamps, sockets and switches, checking their insulation resistance. And after the final installation, before installing the lamps, check the total resistance of all lines and all apartment wiring as a whole. Moreover, when checking the insulation resistance, you can simultaneously check the absorption coefficient and conduct insulation tests megohmmeter at 2500, after which check the insulation resistance again. And assemble the entire circuit apartment electrical wiring and then measuring the insulation resistance of individual lines is not correct.

Order:

Insulation resistance measurement service in Moscow

Electrolaboratory EnergoServiceGarant» provides insulation resistance measurement services. You can order a measurement of the resistance of the sheath of cables and wires from us. favorable prices, which we will hold at any residential, industrial and commercial facilities in Moscow.

Cores in electric cable separated from each other by a special insulating sheath, the resistance of which, ideally, should be infinite. But in practice, there is a leakage current between live conductors, therefore, with the deterioration of the insulating properties of the cable sheath, fires and short circuits. , carried out in a timely and regular manner, allows you to avoid the occurrence of unpleasant situations.

Insulation resistance measurement frequency

The frequency of measuring the resistance of the cable sheath, according to clause 62.2.1 of GOST 50571.16-2007, is a time interval that is determined by the consumer of the electrical installation. But in Appendix 3.1 of the PTEEP, this time interval is specified: it says here that it is necessary to measure the resistance of electrical wiring in outdoor installations and especially dangerous premises annually. At other sites - once every three years.

Carrying out measurements of insulation resistance - features

Measurement of the resistance of the cable sheath is carried out with a special device - a megaohmmeter. This device generates a given voltage and measures the resistance level.

The method for measuring resistance is quite simple. It consists of three stages:

Megohmmeter generates measuring voltage.

The device determines the leakage current that passes between the conductors.

The resistance of the insulating sheath is calculated, which is a quotient of the listed values.

It should be noted that the number of measurements may differ depending on the number of cores in the cable. For example, if the cable consists of:

out of phase and neutral wire, only one measurement is carried out;

from the phase, neutral and ground wires, three measurements are taken;

from three phases and a neutral wire - six measurements;

three phases, neutral and ground wires - ten measurements.

It is mandatory to carry out only when all equipment is disconnected from the network. If the electrical installation is connected to voltage, when it is applied, the semiconductor circuits of electrical appliances may fail. The electrical personnel of the customer must turn off the devices before conducting electrical tests. Measurement of the cable sheath resistance under voltage is not carried out!

The results of the work on measuring the insulation resistance

The resistances allow timely assessment of the condition of the insulating sheath and, if necessary, taking measures to partially replace the wiring, which, in turn, exclude equipment breakdowns and the possibility of fire in the room. Also, verification is required for oversight bodies. For example, Rostekhnadzor, in the absence of a technical report and protocols with measurement results, imposes liability on the enterprise in accordance with Article 9.11 of the Code of Administrative Offenses of the Russian Federation. In addition, the protocols of measurement results may be required by inspectors of the State Housing Inspectorate.

You should be aware that the protocols that are drawn up by an electrical measuring laboratory with its own certificate of registration with Rostekhnadzor are considered legally significant, that is, such as EnergoServiceGarant».

After the specialists of the electrical laboratory carry out resistance measurements and complete all the results in the necessary way, the employee EnergoServiceGarant» will present to the customer . It will include not only protocols with the results of testing the resistance of the insulating sheath of cables and wires, but also a defective statement with comments and recommendations for correcting defects, as well as a copy of the laboratory registration certificate.

If you still have questions about the work of the laboratory EnergoServiceGarant", write to us in a special form feedback on the website or call, or contact us via Email. It is desirable that you voice your requirements immediately when contacting our company - this will allow us to evaluate the approximate scope of work and provide you with an estimate for their implementation.

Qualified measurements of insulation resistance consist in measuring the insulation resistance of electrical wiring and electrical line connections.

Losses of electric current are directly dependent on the state of insulation of electrical wiring, they are associated with its leakage from electrical system in areas with poor insulation, human safety and the ability to operate continuously without accidents. To prevent such troubles from happening, it is necessary to specifically observe the rules aimed at the design and operational rules of electrical networks.

Measurements of insulation resistance of electrical wiring using special ways and equipment must be carried out with a certain frequency on all power lines and power networks, only in this way it makes it possible to preliminarily determine the degree of deterioration of electrical insulation and its properties. In this case, the insulation resistance of the wire is measured in relation to the remaining grounded wires. When the ongoing measurement gives a negative result, then the insulation resistance of all wires is measured separately from the ground and relative to neighboring wires.

Insulation resistance measurements, the frequency for which is provided, is as follows:

- six measurements for 3-wire networks;

- four and ten for 4-wire;

- five and fifteen for 5-wire.

In the case when the operated electrical wiring has an insulating resistance of less than 1 MΩ, then the conclusion about its suitability is made after the checks alternating current, which has an industrial frequency of 1 kV.

Acceptance measurements

Similar measurements of insulation resistance are carried out at the end of all electrical work. The technical report, which is drawn up in accordance with the tests carried out, is part of the set of documents and is necessary for commissioning the electrical installation.

Regular measurements

Regular measurements of insulation resistance, grounding devices, etc. are necessary in accordance with the requirements of regulatory authorities (energy control, fire control, sanitary and epidemic control). The period between periodic checks depends on the type of installation, operating conditions, as well as the requirements of the regulatory documents.

Preventive electrical measurements

Insulation resistance measurements for preventive purposes are carried out to identify faulty or non-compliant operating electrical installations. This is done in order to prevent injury to the worker, fire electrical wires.

Indicators of insulation resistance of electrical wires

The main indicators include the following:

- Insulation resistance direct current. The existence of internally and externally defective defects (damage, appearance of moisture, contamination on the surface) lowers the insulation resistance. This factor is achieved by measuring the leakage current that passes through an insulating material when a rectified voltage is applied to the latter.

- absorption coefficient. This indicator shows the humidity insulating material. It is the ratio of the resistance value one minute after the megger voltage (R60) is applied to the resistance of the insulating material after 15 seconds (R15). In the case when the insulating material is dry, this coefficient exceeds 1, and when the insulation is wetted, the absorption coefficient approaches 1. The number of this coefficient should differ from industrial indicators by no more than 20 percent, and its reading should correspond to 1.3 or more under conditions temperature from 10 to 30 ° C. If, according to the results of measurements, the insulating material is determined to be wet, then the device must be dried.

- Polarization coefficient. He talks about the movement of charged particles in a dielectric material under the influence of electric field, this also indicates the level of deterioration of the insulating material. Such a coefficient must necessarily be greater than 1. This indicator is presented as the ratio of the measured resistance 10 minutes after the megger voltage (R600) to the insulation resistance after 30 s. (R60).

Qualified measurements of insulation resistance

Qualified measurements are carried out using special equipment - a megohmmeter and directly by specialists who have the appropriate permit to carry out this kind of measurement work. The number of measurements depends on the number of electrical wires in the power line - usually from five to fifteen times. The result of the insulation measurement is the previously mentioned basic coefficients, and the decision made on the possibility of using the insulating material or its replacement depends on their value.

In the process of measuring the electrical system, a technical report is drawn up in a certain form (including the protocol for measuring the insulation resistance). The technical report, which is compiled based on the results of the electrical system check, is certified round seal electrical measuring institution, which carried out the corresponding measurements.

Measurement (measurement) of cable insulation resistance

All distribution group networks are tested. Tests for the measurement of insulating material are carried out exclusively in compliance with existing rules according to safety regulations, this must certainly be observed in order to avoid the occurrence of violations in the work, or at least to reduce the problems that arise to a minimum.

Approved insulation resistance measurements, the frequency of which, in accordance with regulatory documents, is provided once every 3 years, do not exclude the implementation of such checks more often, because undesirable phenomena may occur, which can then affect normal functioning the entire system or part of it.

In accordance with special normative documents, measurements of insulation resistance are carried out. Regulatory documents in force on present stage, determine technical standards to be used in the production of such works.

The current technical standards determine the following frequency of test work, which provides for measurements of insulation resistance ( regulations- PTEEP, etc.):

- annually - on a crane and an elevator;

- once every three years for electrical wiring(including the lighting line);

- annually - in premises classified as dangerous and at an outdoor installation;

- annually for electric stoves stationary type.

The Energy Control Administration, as well as the Fire Control Service, are authorized to oblige test work in accordance with the stated requirements. At the same time, they indicate the deadlines for the implementation of such tests.

Measurements of insulation resistance of lighting networks

Test work on lighting networks are carried out with a megohmmeter for a voltage of 1000 V and are as follows:

- measurements of the insulating material of backbone networks - from 0.4 kV assemblies (main switchboard, ASU) to auto switches (SC) of distribution or group (depending on the scheme) shields;

- measurements of the resistance of the insulating material from the installation site of distribution boards (on floors) to the points of local boards (in apartments);

- making measurements of the insulating material of the network from the point of installation of the fuse (automatic switch) of local, group shields (SC) to lighting devices (including lamps).

The value of the resistance of the insulating material on any segment of the line must correspond to at least 0.5 MΩ.

Conditions for performing measurement work

Measurements are taken at outdoor temperature from 15 to 35 °С and relative humidity less than 80%.

The assessment of the state of the insulating material is carried out according to the above parameters (coefficients).

Insulation resistance measurement - absolutely required action, which ensures the safety of the operation of the electrical network in any buildings and types of premises. It must be carried out regularly, in accordance with the requirements of GOST.

With today's variety of electrical appliances and electrical engineering, the load on the power grid increases many times over. At the same time, the threat of emergencies in connection with the failure of one of the circuit elements also increases. This can lead to fires and property damage.

Measurement of insulation resistance is carried out, as a rule, in the lighting network. To do this, specialists take indicators on trunk lines and common switchboards, and then on the billboards in each apartment. Also, the measurement of insulation resistance affects switches, sockets and lighting fixtures.

Many homeowners or commercial premises do not even think about the need for such a procedure. Most of them just don't know about it. Meanwhile, such neglect can turn into sad consequences. Let's explain why.

Electrical wiring, as well as many other things, wears out over time, loses its safety and reliability qualities. Wires are subjected to heavy loads every minute, so their insulation wears out. In some cases it happens quickly, in others it takes longer. No one, even a highly qualified specialist, can predict the exact time when a failure may occur.

Another important point when measuring the insulation resistance is simply necessary. This is the case when you did the wiring. It doesn't matter if you made it new apartment or replaced the wiring in the old one. In any case, you simply have to contact specialists to measure the insulation resistance, because before the complete commissioning of the entire electrical network, you need to make sure that no damage to the circuit and wires was allowed during the installation work.

In addition, a report on insulation resistance measurements is necessary for all landlords, since it is precisely this report that employees of the Ministry of Emergency Situations pay close attention to during inspections. Also, when commissioning facilities, a technical report with data on the state of insulation resistance is one of the points of permits.

To spend everything necessary procedures for measuring insulation resistance, use the so-called electrical laboratory. In fact, this is a set of tools, tools and methods used in the conduct of relevant work.

The specialists of the electrical laboratory measure the resistance both for preventive purposes and for the purpose of diagnosing the electrical network in case the customer makes any complaint about the malfunctioning of one or another element of the electrical circuit. Employees find out the causes of failures in its work, give recommendations for their elimination and further correct operation and also fix these problems.

By the way, in addition to measuring insulation resistance, it is extremely useful to periodically test the electrical network itself in order to identify weaknesses and thereby prevent serious problems in the future. For this, as a rule, measures are taken to test the RCD and ATS, grounding devices, protective equipment and ground loop.

As for measuring the insulation resistance, it must be carried out regularly. In accordance with the requirements of regulatory and technical documentation (PTEEP), insulation resistance measurements are carried out at the following intervals:

As a result of the work done, you receive a technical report in accordance with GOST R 50571, containing information on the state of the electrical installation, presented to inspectors of the state fire supervision and the federal department for environmental, technological and nuclear supervision (ROSTEKHNADZOR).

In order to measure the insulation resistance, you need to contact specialists who, in addition to licenses and permits for such work, also have great experience. In our company, all work is carried out by highly qualified specialists.

We carry out the following works:

- loading machines;

- drawing up single-line diagrams;

- insulation resistance measurement;

- ground resistance measurement;

- measurement of transient resistance;

- dimension resistivity soil;

- measurement of parameters of a short circuit loop;

- measurement of device parameters protective shutdown etc.

Experience and professional level of our employees allows us to cope with the most serious tasks. We carry out electrical measurements and equipment testing up to and above 1000 V.

We have our own electrical laboratory: certificate of registration of the electrical laboratory dated December 05, 2013 No. 553/130-13.

We offer insulation resistance measurements up to 30% more profitable than other similar companies. Departure for drawing up estimates and determining the work is free of charge.

The cost of measuring insulation resistance

The cost of measuring insulation resistance in our company starts from 3,500 rubles (including all expenses).

Scheduled inspection and repair of electrical equipment is not always effective. To identify damage and malfunctions at an early stage, to prevent emergency situations allows thermal imaging inspection of electrical equipment.

Our company conducts thermal imaging inspection of electrical equipment when performing insulation resistance measurements.

When contacting us, thermal imaging of the switchboard as a gift!