To ignite gas-discharge lamps, including sodium lamps, you will need specialized ballast equipment (ballast control equipment), because direct connection of HPS lamps to the network is excluded.

Ballasts for sodium lamps (HPS) include:

- IZU (pulse ignition device), which ensures the start of a gas-discharge lamp. At the moment it is turned on, the IZU transmits powerful high-voltage pulses to the electrodes, due to which a breakdown occurs in the gas mixture of the flask and the arc is ignited. After this, the issuance of explosive pulses stops, however, as does the influence of the pulse ignition device on the operation of the lamp;

- Throttle. Although electronic ballasts are considered more productive, their cost is much more expensive than pulsed ones. Therefore, the most common and in demand for connecting a HPS lamp is an inductive choke. The electric choke is presented in the form of a small block, which must correspond to the power consumption of the lamp. It limits and stabilizes the current supply, strongly resists any changes, maintains a decreasing current and prevents its increase, thereby ensuring long-term performance properties of the lamp and high luminous efficiency.

Thus, the ballast provides standard heating and effective work sodium lamps for the entire period stated by the manufacturers.

HPS connection. Scheme

Possible different methods connections of gas-discharge lamps, in this case HPS: IZU manufacturers can offer a design with two or even three contacts, with a parallel, serial and even semi-parallel type, which significantly changes the HPS connection scheme. It is displayed on almost all devices of this type, which eliminates installation errors.

The connection diagram for the HPS lamp, which is shown in the first figure, is designed to contain a compensating capacitor connected in parallel to the power source. This is a dry type C capacitor, which is designed to compensate for the inductive component of the system - reducing power consumption reactive power, reducing overall energy consumption, as well as to extend the service life of the finished product.

For example, to connect a HPS lamp with a power of 250 W (3A), a compensating capacitor capacity (operating voltage indicators - 250V) of only 35 μF is provided. This capacitance can be formed using several capacitors connected in parallel.

Sometimes capacitance indicators may be provided by the manufacturer, but an extremely large increase can lead to resonance in the circuit, and, consequently, to ineffective operation of the finished product.

If the HPS connection occurs independently, you should take into account valid value location of the IZU. It should be located as close as possible to the base of the product, while the length of the connecting wires in this area should be minimal (the maximum permissible value is 1.5 m).

To ensure a high-quality and safe connection, high-voltage ignition wires for special purposes are used.

Reviews

Guest- 07 Feb 2014 23:58:53

In my opinion, the phase in the lamp is where you have zero.

Igor- 08 Feb 2014 14:56:03

In fact, the lamp will work well with any connection of phase and zero to its base.

But there is a safety issue.

And here you are right.

The pictures do not show the socket into which the lamp is screwed.

For clarity, I omitted it from the diagram.

Assuming that you are unscrewing a burnt-out lamp and at the same time:

1.phase is connected to the threaded part of the cartridge (as in the pictures)

2.You forgot to turn off the switch, or it opens zero, not phase

Then when you touch the base you will get a good knock.

And if the phase is connected to the central contact of the base, then the chance of electric shock is minimal.

But personally, I would unscrew the lamp while holding onto its glass bulb. When the power is off. And I wouldn’t think about the connected phase.

But anyway, thanks for the clarification.

Vitaly- 18 Feb 2014 8:57:24

And what should the phrase “...IZU manufacturers can offer a design with two or even three contacts...” mean? All normal manufacturers of sodium lamps, Philips, OSRAM, General Electric, launch their sodium lamps exclusively in series or semi-parallel circuits, with the exception of lamps with a built-in ignitor. And this means the presence of exactly three contacts. A parallel ignitor (which has two contacts) cannot be used to start such lamps, since the vast majority of ballasts do not have protection against high-voltage pulses and will fail very quickly. Therefore, parallel connection used to start sodium lamps low pressure or metal halide lamps designed to operate with mercury ballast and do not require high-voltage starting pulses. Based on this, I undertake to assert that scheme No. 2, made up of precisely these components, is not correct. The VS catalog, whose ballast is used for the example, can confirm this. The DeLux ignitor was used to start sodium lamps only in combination with a ballast specially produced for this circuit.

What am I doing wrong?

Alexey- 02 Oct 2014 23:16:14

Hello, could you please tell me the connection diagram for the Philips sox-e 131w low pressure lamp?

When using conventional scheme with a two-pin izu it starts to twitch, but does not light up

Guest- 04 Nov 2014 11:48:27

everything lights up perfectly with any ignitor connection diagram, both parallel and serial 3-pin!!!

Sergey- 29 Nov 2014 10:08:52

Good afternoon, could you please tell me the connection diagram:

1 gas-discharge sodium lamp lhp-t 100 W

2 isut 70-700DNaT/220v-02.ukhl2 (2 contacts)

3 ballast galad 1i250drl44-033uhl1 (three contacts, and they are marked 1 2 3)

thanks in advance

Photosynthesis is the cornerstone of plant nutrition. And the first half of this word “photo” clearly tells us about the participation of light in this process. When growing plants hydroponically at home, you will definitely encounter the need to create artificial lighting for your green spaces. I don’t argue that there are natural lighting conditions that are close to ideal: large windows, sunny side, lack of houses opposite the windows, southern latitudes, eternal summer... But in most cases the need for at least additional lighting artificial light still exists.

And we need to choose what type of artificial lighting to use. In addition to the household criteria for choosing the type of lamp, such as cost, efficiency, ease of use, there is another one for the grower: important criterion- emission spectrum of the lamp. There is already information about spectra on our website, but, in short, the point is that plants need light of certain wavelengths - mainly in the red and blue parts of the spectrum. But lamps differ greatly in this indicator, and most of the lamps existing on modern market, is eliminated precisely due to non-compliance with this requirement. These include incandescent lamps, ultraviolet lamps, most halogen lamps and some others.

Types of plant lamps

But there are lamps that more or less satisfy the needs of plants, and which are successfully used in home and industrial plant growing. These include:

- Some energy saving lamps.

They are ineffective, but they can be used when located close to plants and with a large number of lamps. Different “energy savers” vary in spectrum, so you need to experiment with them and choose those to which plants respond best. - Fluorescent lamps.

There are different spectrums, suitable and not so suitable. In plant growing, it is recommended to use T5 and T8 lamps. They also require close proximity to plants, and large quantity lamps Often used as an addition to the main light, or as the main lighting for growing seedlings. - Light emitting diodes, LED.

Recently appeared on the market and are very promising, but at the moment they are active use constrained by the high cost of lamps. - Mercury vapor lamps high pressure, DRL.

They can be used as the main light, but have their drawbacks: low light output and high temperature. - Metal-halogen lamps, MGL, DRI.

Actively used as main and additional lighting. They have a lot of blue light in their spectrum, which is used by plants at the vegetative stage of growth. Therefore, these lamps are good for growing plants that value the green part. - High pressure sodium lamps, HPS.

The most popular and actively used lamps at the moment. The spectrum is well suited for growing fruit-bearing plants. Like other lamps, it also has its drawbacks: a certain lack of blue component of the spectrum (solved by additional illumination with other lamps), and strong heating during operation.

Launch of DNAT

Due to its design, the HPS lamp cannot be connected directly to our home electrical network- the mains voltage is not enough to ignite a cold lamp. In addition, the lamp arc current must be limited. Therefore, HPS lamps are used in conjunction with Starting-Regulating Devices (PRA)- electromagnetic ( EmPRA) and electronic ( electronic ballast).

In Western terminology, these devices are called ballasts - Magnetic Ballast and Digital Ballast, respectively. You can read about foreign-made electronic ballasts in, and here we will look at the device and process self-assembly electromagnetic ballast.

Design and assembly of ballasts - starting and regulating apparatus for a HPS lamp

So, the ballast uses only three components:

- Inductive choke. It just limits the arc current. Price from 600 rub, depends on the manufacturer, power. The power of the choke must match the power of the lamp. Those. for a DNAT 250 lamp, we are looking for a 250 W choke in the store.

- IZU is a pulse ignition device. Immediately after switching on, it generates voltage pulses of several thousand volts, which create an arc. Price from 300 rub.. When purchasing, we also pay attention to the power. IZUs have a power range, for example 35-400 W. We make sure that the power of our lamp falls within this range.

- Phase compensating capacitor. This component may be missing, but its use provides additional benefits. Price from 150 rub.. The parameters of capacitors will be discussed below.

When purchasing a choke and IZU, check with sellers whether the products they offer are suitable for use with HPS lamps. According to some information, for HPS lamps and DRI lamps they are used different components. I would be glad to receive a competent opinion on this issue in the comments to this article..

All components can be found on sale in electrical markets. The components are of both domestic and foreign (Israel, Germany) production. On the Internet, as usual, they criticize domestic ones and praise imported ones.

The ballast circuits look like this:

Options with two- and three-pin IZUs are presented - both are available on sale. The third diagram shows an option using a phase-compensating capacitor (indicated in the diagram WITH). In a circuit with a three-pin IZU, the capacitor is connected in the same way, in parallel. On the IZU and on the inductor you will see similar diagrams, but more detailed, indicating the contact markings of your specific devices. Be sure to follow these markings! If you are careful enough, there should be no problems during assembly.

When assembling and using these circuits, you need to pay attention to which wire the phase is supplied through. Studying materials on the Internet, I came to the conclusion that this important point(if I'm wrong, correct me in the comments). Solving this issue, I marked the plug and socket, indicating the phase on them.

It is also convenient to use the colors of the wires when assembling the circuit. This speeds up installation and eliminates the need to call them. The rules are:

- Working zero (N) – blue, sometimes red.

- Phase (L)– can be white, black, brown.

- Null protective conductor(PE)– yellow-green color.

For connection three wires at one point (zero from the lamp, from the IZU and from the plug), it is convenient to use a three-pin terminal block.

All electrical connections performed thick stranded wire, soldering (if any) must be reliable. The screws in the connecting blocks must be tightened tightly, but without excessive force, so as not to break the block.

This is what my assembled ballast for DNAT 250 looks like:

Capacitor in ballast circuit

You may have noticed that I did not use a capacitor in my circuit. Unfortunately, I simply did not find it for sale. Why do you need a capacitor in the ballast circuit for HPS, since the circuits work without it? The bottom line is that using a phase-compensating capacitor can reduce the load on your home electrical wiring and on the circuit of your lighting device in particular. You will be told in more detail and very clearly about the advantages of using a phase-compensating capacitor in this video.

We select the capacitor capacity for our circuit according to the following table:

Lamp powerCapacitor 220V~50Hz 150 W20 µF250 W32 µF400 W45 µF600 W60 µF1000 W85 µF

Safety

Due to design features HPS lamp, when experimenting with it and its further use, the following precautions should be observed:

- Do not turn off the lamp immediately after turning it on. It should burn for a minute or two. After a short-term shutdown, the lamp “freezes” and does not turn on. To turn it on, you need to unplug the lamp and let it “rest”.

- Provide good ventilation for the lamp. The temperature of a working HPS lamp is much higher than 100 degrees C (according to some sources, up to 1000 degrees!). Therefore, good ventilation is not only a guarantee of the well-being of your “plants”, but also your personal safety. Do not touch the operating lamp or its reflector.

- Try not to touch the lamp at all. Before installation, wipe the lamp clean soft cloth, do not handle the lamp with bare hands. It is best to use cloth gloves. The fact is that due to the same high temperature, any foreign deposit (fats, water) on the lamp bulb can cause it to explode. They write a lot about this on the Internet, but here is a wonderful video on this topic.

- Depending on the power, Ballast can also get very hot- from 80 to 150 degrees. Therefore, you need to somehow solve the issue of protection from high ballast temperatures. For example, isolate the ballast in a reliable fire-resistant casing, prevent paper, fabric, and dry leaves from getting on it.

- Observe general safety precautions when working with electricity. Avoid the possibility of water getting into the ballast, move it away and hang it higher. The wires must have complete insulation; it is better to use special wire for harsh conditions. Remember that at the moment the lamp is ignited, the IZU produces very high voltage pulses. This is in addition to the “regular” 220 volts, which are present throughout the entire circuit.

GORSHKOFF.TV

In this article I have mentioned several times a video from a wonderful YouTube channel GORSHKOFF.TV. Perhaps this is the best popular science (I’m not afraid of this word) channel dedicated to hydroponics that I have ever come across! I highly recommend that you all watch all the videos on the channel, and I’m looking forward to the appearance of new educational materials, and I also express my deep gratitude for this activity personally

Sodium lamps, compared to other sources of artificial lighting, demonstrate the most high efficiency- close to 30%. To save money cash It is recommended to buy high pressure bulbs. The light emitted by high-pressure sodium lamps allows one to distinguish colors in almost the entire range, excluding only short-wavelengths, in which the color fades somewhat. Let's talk today about the emergence, use and connection of sodium lamps with our own hands.

Historical background

The biggest contribution to street lighting was made by sodium discharge lamps high pressure, which are the main obstacle to astronomical observations. Let's delve into history to understand what they are. Tubular lamps, which exhibit low mercury pressure, were invented in the pre-war period.

Such fluorescent lamps quickly became widespread. But it was not possible to obtain a discharge in sodium vapor for a long time, this was explained by the low partial pressure sodium at low temperature. After a complex of technological tricks, sodium lamps were created that operated at low pressure. But because complex design they are not widely used.

But the fate of sodium lamps, which operate at high pressure, was more successful. Initial attempts to create lamps encased in quartz glass ended in failure. At high temperature The chemical activity of sodium increases and, as a result, the mobility of its atoms increases. Therefore, sodium in quartz burners penetrated quickly through the quartz, destroying the shell.

The emergence of sodium lamps

The situation changed dramatically in the early sixties, when the General Electric company patented a previously unknown ceramic material that could work in sodium vapor at high temperatures. It received the name “lukalos”. In our country, this ceramics is known to the inhabitants as “polycor”.

This ceramic is produced by high-temperature sintering of aluminum oxide. For lighting purposes, only one modification of it is considered suitable. crystal lattice- the alpha form of the oxide, which has the densest packing of atoms in the crystal.

The sintering process for such ceramics is very capricious, because it must be chemically resistant to sodium vapor and must have high transparency so that most of the light is not lost in the walls of the discharge tube. Sodium vapor, which serves as a gas-discharge medium in sodium lamps, produces a bright orange light when illuminated. Because of the presence of sodium in the lamp, the abbreviation DNAT came into use, which means sodium arc lamps.

Advantages and disadvantages of sodium lamps

Sodium lamps are twice as effective as regular lamps daylight similar power - this can be explained by the small size of the emitter, the light rays from which are much more easily directed in the desired direction, and other design features.

In addition, using sodium arc lamps you will be able to recreate much greater illumination. Its ceiling for daylight fixtures reaches 50 watts per square foot, and with the help of sodium lamps you can achieve 3 times more without any problems!

From an economic point of view, sodium lamps are more profitable - they only need to be changed once every six months, and 1 DNAT-400 lamp can successfully replace 20 40 V LDS. It is also much more convenient to work with a medium ballast than with 15 small ones. Since sodium lamps use electricity twice as efficiently, when using them, a certain result is achieved at half the cost.

The efficiency of sodium light bulbs is directly dependent on temperature external environment, and this in turn slightly limits their use, because they shine worse in cold weather. It is also not entirely clear that they are more environmentally friendly than mercury lamps, since most sodium lamps use a compound of sodium and mercury as a filler - sodium amalgam.

Using sodium lamps

Typical objects where sodium lamps are used: highways, streets, squares, long-haul tunnels, airfields, traffic intersections, sports facilities, construction sites, airports, train stations, architectural structures, warehouses and production premises, pedestrian areas and roads, as well as additional lighting sources.

If you want yours personal plot somehow decorate, then you can buy sodium lamps, which were found in landscape design its application. Due to the characteristics of sodium lamps, warm and bright orange light, they are used for auxiliary purposes for a unique decorative effect, which simulates open flame or sunset.

Purchasing sodium lamps is useful if the owner grows seedlings and has winter garden, greenhouse or conservatory. Of course, sodium lamps will not replace natural light and sunlight, but your plants will not be affected by the changes. weather conditions and cloudy days will not be affected if the flowers are illuminated with such lamps.

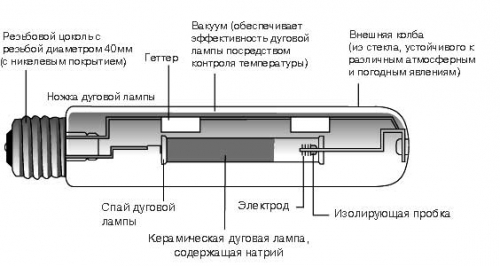

Operating principle of a sodium lamp

Inside the external cylinder of DNAT there is a “burner” - a tube that is made of aluminum ceramics and filled with rarefied gas, in which it is created between two electrodes electric arc. Sodium and mercury are introduced into the burner, and inductive ballast or electronic ballast is used to limit the current.

The mains voltage is not enough to ignite a cold sodium lamp, so the principle of operation of a sodium lamp is to use a special IZU - a pulsed ignition device. Immediately after switching on, it generates voltage pulses of several thousand volts, which are guaranteed to create an arc. The main radiation flux is generated by sodium ions, so their light has a characteristic yellow color.

The burner heats up to 1300 degrees Celsius during operation, so air has been pumped out from the external cylinder to keep it intact. For all sodium lamps without exception, when operating, the temperature of the cylinder exceeds 100 degrees Celsius. The lamp shines weakly after the arc occurs, all energy is spent on heating the burner. The brightness increases as it warms up and after ten minutes reaches normal levels.

Types of sodium lamps

If the economical operation of light over a long time is more important to you, then it is best to purchase low-pressure sodium lamps, which are characterized by high levels of operational reliability, light output over a long time and energy efficiency.

Sodium lamps are ideal for organizing street lighting because they are capable of emitting the monochrome color familiar to people. yellow, but do not have sufficient transmission of the light spectrum.

For other purposes, the use of low-pressure lamps is considered difficult because the colors of objects illuminated by such a lamp cannot be distinguished. The color perception of objects indoors is distorted (for example, green turns into dark blue or black), and the design appearance of the premises is lost.

To save money, it is recommended to buy high-pressure sodium lamps. Connecting high-pressure sodium lamps is most suitable for gyms, industrial and commercial complexes. The light emitted by high-pressure sodium lamps allows colors to be distinguished in almost the entire range, except for short wavelengths, in which colors may fade somewhat.

Installation of sodium lamps

Sodium lamps got enough today wide application in various sectors of the economy, however, due to insufficient transmission of the color spectrum, they are most often used as street lighting. Sodium bulbs, unlike metal halide bulbs, do not care in which position they operate.

However, based on many years of practice, it is believed that it is more effective horizontal position lamps, because it emits the main stream of light to the sides. To connect any HID lamp, a ballast is required. Sodium lamps are no exception in this sense; ballast is required for their “warming up” and normal operation.

Ballast

For sodium lamps, the ballast is a ballast, electronic ballast and pulse ignition device. Undoubtedly, the best ballasts are rightfully considered electronic, which have a number of advantages over inductive ballasts, losing to the latter in cost: currently their price is quite high.

The most common ballasts are ballast inductive chokes, which are necessary to limit and stabilize the current. The necessary ballast, which is connected to the lamp in the required way, is already present in them, so the connection diagram for sodium lamps comes down solely to supplying supply voltage to the terminals of the lamp.

Today, double-winding chokes are outdated, so you should give preference to single-winding ones. Regular throttle domestic production You can buy it at the company for about 10 dollars, and at the market - half the price.

It must be intended specifically for HPS and have the same power as the lamp. It is necessary to install a “original” choke, otherwise the lamp’s service life may be reduced several times, or the light output will drop catastrophically. It is also possible to “blink” when the sodium lamp goes out immediately after warming up, then cools down, and everything happens all over again.

Pulse ignition device

IZUs are required, as described above, to light the lamp. IZU manufacturers produce devices with 2 and 3 pins, so the sodium lamp switching circuit may differ slightly. But usually it is depicted on each IZU case. Of the domestic IZUs, the most convenient is the “UIZU”; it is suitable for lamps of any power and can work with all ballasts.

![]()

In this case, you can place the UIZU next to the ballast and near the light bulb, connecting it to its contacts. Polarity does not play a special role when connecting the ICU, but it is recommended that the “hot” red wire be connected to the ballast.

Noise suppression capacitor

Arc sodium lamps are consumers of reactive power, so it makes sense in some cases (in the absence of phase compensation) to include an interference suppression capacitor C in the sodium lamp circuit, which significantly reduces starting current and prevents unpleasant situations. For chokes DNaT-250 (3A) the capacitance of the capacitor should be 35 μF, for chokes DNaT-400 (4.4A) - reach 45 μF. Dry type capacitors should be used rated voltage which are 250 V.

Connections are usually made with thick stranded wire of large cross-section, network cable must also count on high current. Make solderings reliable. Tighten the screws tightly, but without excessive force, so as not to break the block.

At self-connection sodium lamps, it is worth considering this recommendation - the length of the wires that connect the ballast to the sodium lamp should not be allowed to exceed more than one meter.

Security Issues

If you assembled the lamp yourself, make sure that its connection diagram is absolutely correct. If the connection diagram is not drawn on your ballast, or the number of legs on the ballast/IZU does not match the diagram, you should consult with the seller of these parts or an experienced electrician. The consequences of such an error are catastrophic: burnout of one of the 3 elements of the circuit, knocking out the plugs, explosion of the lamp and fire.

If there is grease or dirt on the sodium lamp cylinder, it may burst due to uneven heating immediately after warming up. Therefore, do not touch the lamp with your hands and wipe it with alcohol just in case after installing it in the socket. If drops of water or other liquids come into contact with a switched-on lamp, this provokes an explosion with 100% probability!

When using a fan, it is worth checking that it blows and rotates where it should. The lamp must be hung securely to avoid falling - a sodium lamp is heavy and can break something if it falls. When repairing a lamp, some measurements should be made with the device turned on - do not do this yourself unless you have sufficient experience working with high voltage devices.

While the sodium lamp is operating, once a month, wipe off dust from the lamp and reflector and check the condition of the fan. It is recommended to change sodium lamps every 4-6 months, since towards the end of their useful life their light output drops significantly.

Sodium lamp malfunctions

As sodium lamps age, they acquire the habit of “blinking”: the lamp turns on, warms up as usual, then goes out unexpectedly, and everything repeats after a while. If you notice this behavior in your lamp, you should try changing the light bulb. If changing the lamp does not help, you need to measure the voltage in the network; maybe it is slightly lower than usual.

If the sodium lamp blinks irregularly, the reason lies in poor contact or power surges in the network. The most unpleasant situation is a short circuit in the ballast between the turns of the winding, then it needs to be changed. Sometimes new lamps may flash, but this goes away after a few hours.

You can often hear the IZU crackling after turning on the lamp (a sign of operation), but the lamp does not even try to light up. This happens most often due to breakdowns in the wire that goes to the lamp from the IZU, or indicates a burnt-out lamp. A broken wire between the lantern and the ballast or a burnt IZU may be to blame.

You can try changing the wire between the lamp and the IZU. It is also worth paying attention to the IZU contacts and their condition. If it doesn't help, change the lamp. If this does not help, turn off the IZU, because it can burn the voltmeter with its impulses, and measure the voltage on the lamp socket - it should correspond to the mains voltage at the DNAT. If there is voltage on the cartridge, change the IZU.

If the sodium lamp shows no signs of life at all: the IZU does not buzz, the lamp does not glow - most likely the contact in the power cord is broken or the fuse is blown out. Maybe the IZU burned out, or a winding break occurred in the ballast - check the ballast, if it is intact, it is worth changing the IZU.

The ballast can be checked with a regular Ohm meter. Their normal resistance is 1-2 ohms. If the indicator is significantly higher, it means that there was a break in the winding or the contact between the connecting block and the winding terminals was broken (tighten the screws).

Everything is more complicated with interturn closure - it affects the resistance DC very little, so it is difficult to detect, and more power is supplied to the lamp than necessary. When a sodium lamp is overpowered, the lamp overheats quickly and goes out, and as a result, “blinking” can also be observed.

Now you know how to connect sodium lamp! In conclusion, it is worth noting that sodium arc lamps are one of the most effective categories of visible radiation sources, because they are characterized by the highest light output of all gas-discharge lamps known to mankind and a slight decrease luminous flux with a long useful life.

(322

votes, average: 4,83

out of 5)

HPS lamps: a light source that was retired too early.

As we promised, an article about HPS lamps(Arc Sodium Tubular High Pressure). Everyone who has worked or is working in the field of lighting technology has heard about this monster. But if anyone hasn’t heard, let’s explain it in simple terms: HPS lamps are like a Kalashnikov assault rifle for lighting streets and illuminating plants - a time-tested and reliable, but not without its shortcomings, light source.

Actually, this article about HPS lamps is more for beginners; material presented competently, but accessible language: without circuit diagrams connection and complete understanding of the basics of maintaining the discharge column in the burner of a HPS lamp. But we are sure that specialists will also like the sketch.

Almost 100% of the world's roads (no one, of course, counted) until recently were illuminated by HPS lamps, until they began to be cut out from their supports in favor of LED lamps. However, even now, experienced designers prefer to stick a sodium lamp into the project out of harm’s way, because LEDs are 1. really more expensive, 2. not that much energy efficient and 3. still unpredictable, because the number is simply overwhelming. But more on that later.

HPS lamps come in different powers - from 50 to 1000 W (rarely, but they are found with a power of 2000 and 4000 W), which seems to hint at their “industrial” use rather than “household”. Basically, HPS lamps are used in lamps for illuminating streets and roads, less often - in production in combination with light sources white light(for example, with lamps on MGL to achieve more warm light and greater energy efficiency). In the most perverted cases, they are put into production in their pure form. And then - before the first injury or the call “where to go.”

But the most indispensable application is lighting greenhouses, or supplementary lighting of plants (which, in fact, is the same thing, but the second is scientific).

Terminology

This is why we don’t like Wikipedia, because what they write there is either superficial and not clear, or boring and with all the details - which is also not clear to the uninitiated. The most offensive thing is that the essence of the name of the HPS lamp is given only as a decoding of the abbreviation, but here everything is much more interesting.

HPS lamps all over the world (except Russia) are called as they should be called - HPS Lamp (High-Pressure Sodium Lamp), that is, high-pressure sodium lamps (HPS). We also call them that, but no one uses this term. In the Soviet Union, when NLVDs first appeared, various factories began to produce them. The modifications and capacities were different and they had to be distinguished somehow.

There were indeed many differences: the shape (ellipsoidal/tubular) and transparency (matte/transparent) of the bulbs, the lamp power (75/150/250/400/600/1000), the presence or absence of mirror coating in one of the hemispheres. So what are the names of NLVD? Soviet made there were a lot. The most common are HPS lamps with various power attachments (150, 250, etc.).

It was something like branding. For example, now in Russia there are DNAT-250 lamps (with a note, “of such and such production”), and in Germany (and all over the world thanks to export, marketing and quality) there is a lamp, for example, VIALOX NAV-T 250 W SUPER 4Y manufactured by Osram.

So, by and large, HPS lamps are just variations of the lamp model, not a type of light source. But the type of light source is NLVD, which includes lamps DNaT, DNaZ (with mirror coating) and even DNaS (with a light-scattering bulb, so that it is less blinding). And, except for specialists, few people know this. That's it.

By the way, if anyone is interested, you can look into the lamp museum (the site is in English, but with a lot of pictures) - there are countless different lamps collected here, incl. and sodium, throughout the history of the era of electric lighting. Very informative.

HPS lamp design

In principle, HPS lamps are no more complicated than any gas-discharge lamp. On the outside there is a flask made of heat-resistant glass and a base, on the inside there is a burner holder and the burner itself. All.

Connecting a HPS lamp

The connection is also primitive to the point of disgrace, as is the design of the lamp. So we won’t dwell on this for long and will just give one of the most standard schemes connecting the HPS lamp.

Although it is worth mentioning here that in reality there are a huge number of options for connecting a HPS lamp. A compensating capacitor is also a mandatory connection component. As a rule, connection diagrams are indicated on the IZU blocks. But the picture above shows the simplest schematic connection option.

Advantages of a HPS lamp

1. Energy efficiency of HPS lamp

This light source is still considered one of the cheapest and most energy efficient (2016). Yes, yes, you shouldn’t make eyes like that. They are quite competitive with LEDs, incl. and according to the lm/W parameter. Yes, with best representatives industry with a power of 250 W it is quite possible to shoot up to 130 lm/W (proof). And from a lamp - up to 90...110 lm/W, depending on the manufacturer, diffuser, reflector, ballast and quality of the supply network.

Interestingly, the higher the power and luminous flux of a HPS lamp, the higher their light output. For example, there are almost no 50-watt lamps above 80 lm/W. But with DNAT 1000 you can safely get 150 lm/W - that’s crazy. Once again, just two years ago such parameters for LEDs in mass production were unimaginable.

It is not entirely correct to simply talk about a lamp without a lamp, because only in it you can see all the pros and cons of the HPS lamp. The energy efficiency of lamps with sodium lamps is clearly illustrated by the characteristics declared by lamp manufacturers on their websites (they rarely lie). But we also have our own measured data obtained from the laboratory during testing of luminaires for rating:

— - 84 lm/W,

— with GE lamp - 81 lm/W,

— - 87 lm/W.

Now comes the most interesting part. If we talk about direct replacement, i.e. when the old sodium lamp was removed and a new LED was hung in its place, you must understand that a lamp with a 150 W HPS lamp can never be replaced with a 50 or 70 W LED. The same applies to 250 W sodium lamps - they cannot be replaced with a 100 or even 150 W LED (we are talking about ordinary lamps, and not about custom-assembled ones with ideal characteristics and a luminous efficiency of 150 lm/W from a lighting device).

2. Price of a HPS lamp

The cost of a HPS lamp varies from 300 to 10,000 rubles, depending on the power, manufacturer, seller and some other variables. An average 250 W light bulb costs around 1000 rubles (±700). But it’s also not entirely interesting to talk about the price of an abstract HPS lamp. It is interesting to talk about the cost of a lamp as part of a lamp with ballasts (starting and control equipment), base, protective glass, etc.

In general, the DNAZ lamp, together with its inventor, deserve a separate article. And we will definitely write it. No. Seriously. Apart from the company's own website, you will find almost no information about this lamp. So we'll fix this.

Hello, dear readers of the Electrician's Notes website.

To get to the terminal block, you need to unscrew 2 bolts with plastic heads (wings) and tilt the lamp.

The cores of the power cable are connected to the terminal block of the lamp as follows:

As you can see, . Phase (L) must be connected to a terminal with two outgoing white wires, zero (N) - with a blue outgoing wire, and the protective conductor (PE) - in the center.

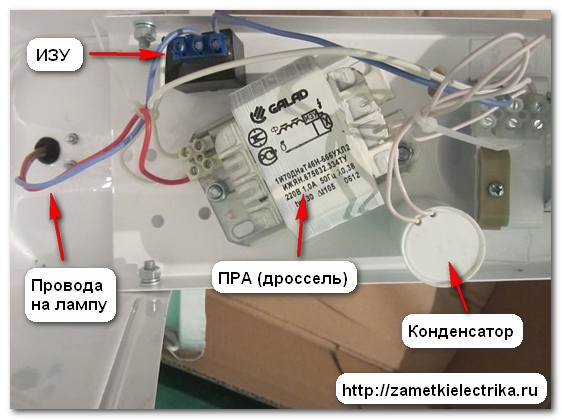

Now let’s look at the internal diagram of the housing and communal services lamp.

Connection diagram for a lamp for sodium lamps

Due to the design features and operating principle of sodium lamps, when connecting them you need:

- pulse ignition device (IZU)

- compensation capacitor

control gear (ballast), also called a throttle or ballast

There are two schemes for connecting HPS lamps:

In my case, the second scheme is used:

I specifically highlighted the wires in the diagram with the appropriate color, which you will see in the photographs below.

Schematic elements

Let's consider all the elements that are included in this diagram:

1. Ballast (choke)

In general, there are two types of ballasts (chokes):

- electromagnetic or inductive (EMPRA)

- electronic (electronic ballasts)

Each ballast has its own advantages and disadvantages. I will tell you about this in my next articles (in order not to miss new articles, subscribe to the newsletter).

The luminaire in question uses a domestic built-in electromagnetic single-winding ballast (choke) “Galad” 1I70DNaT46N-666 UHL2. It is connected in series with the lamp, thereby limiting and stabilizing its current consumption. By the way, it weighs 1.3 (kg) and its retail price is about 350-390 rubles.

My point is that you should be guided by prices, in case you have to change it, because they often fail. There may be several reasons: an interturn short circuit in the winding, or a break in it.

The throttle body shows its connection diagram and some characteristics.

- power 70 (W)

- voltage 220 (V)

- operating current of lamp 1 (A)

- starting current of the lamp is not more than 1.6 (A)

- power factor 0.38

- current consumed from the network 0.54 (A)

- maximum permissible temperature windings in operating mode 130°С

2. Pulse ignition device (IZU)

There are two types of IZU:

- with three terminals

- with two terminals

In our example, we use the domestic compact IZU-1M 35/70-3 from Remar LLC with three terminals. The retail price is about 120-150 rubles.

The IZU is necessary to “start” the HPS lamp. When the lamp is turned on, it delivers a short-term high-voltage pulse of 1.8-2.5 (kV), which ensures breakdown of the gas gap in the lamp bulb.

IZU is not required for DRL lamps.

The connection diagram and some characteristics can be seen on its body.

- voltage 220 (V)

- response voltage 170-195 (V)

- HPS lamp power 35-70 (W)

- parallel connection type

- pulse amplitude 1.8-2.5 (kV)

- pulse duration not less than 1.62 (μs)

3. Capacitor

To increase the power factor (cosine “phi”) of the lamp, a capacitor is used. In my case, this is a polypropylene film capacitor K78-99 with a capacity of 10±10% (uF) with a voltage of 250 (V), which is connected in parallel to the supply network (directly to the terminal block).

Before compensation, the cosine of the lamp was 0.38, after compensation it was 0.85.

Each type of inductor requires a certain capacitor capacity. You can calculate it using formulas yourself, or you can use special tables from manufacturers.

Maintenance of luminaires with HPS lamps

If carried out in a timely manner maintenance lamps, their service life will correspond to that stated in the passport. You just need to periodically perform the following steps:

check reliability contact connections in the terminal block, choke and IZU

clean the lamp from dust and dirt

if the HPS lamp burns out, then install a lamp of the same power in its place, and not more or less

P.S. That's probably all. If you have questions about the topic of the article, I am ready to answer them. Thank you for your attention.