Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru/

Are commonprinciples of conductingelectro installation work

Electrical installation work is part of a complex of construction works and is carried out within the framework of a construction contract (contract), according to which the contractor undertakes to complete the work within the period established by the contract, and the customer undertakes to create for the contractor the necessary conditions to complete the work, accept the result and pay for the work performed.

The customers are legal entities(enterprises, organizations) with financial resources (investors). Financing of electrical installation work is carried out through the section of capital investments provided for new construction, expansion, reconstruction and technical re-equipment of electric power facilities.

Contractors when carrying out electrical installation work are, as a rule, electrical installation organizations, regardless of their form of ownership, registered in the prescribed manner with the tax authorities and having a license and other documents confirming the legality of the organization and quality guarantees for performing electrical installation work. In case of large volumes of electrical installation work and several applicants for their implementation, the customer organizes competitive tenders.

Licensing of the activities of electrical installation organizations is carried out with the aim of protecting the rights and interests of consumers of construction and installation products. Guarantees within the time frame for the customer to file claims against the contractor are determined in the contract and for electrical installation work are usually 1...2 years.

The work contract is the main legal document regulating the relationship between the customer and the contractor. Such an agreement is sometimes concluded for the execution of turnkey work. This implies the implementation of a full investment cycle, including design, construction, electrical installation, commissioning and commissioning of the facility.

To perform a complex or individual types of work, for example, commissioning adjustment work, the contractor may involve other organizations - subcontractors. In this case, the contractor already acts as a general contractor.

Preparation for electrical installation work, in particular, acceptance of the construction part of the facility for installation of equipment, responsibility to the customer for the completion of all types of work within the terms stipulated by the contract of proper quality rests with the general contractor

Organization of electrical installation work

electrical installation work labor protection

The organization of electrical installation work is the responsibility of the contractor and consists of three main stages.

At the first engineering and technical stage, acceptance, verification and study of design and estimate documentation are carried out; V project documentation a construction organization project (CAP) must be provided, on the basis of which the electrical installation organization develops a project for the production of electrical installation work. (PPER).

At the second organizational stage, acceptance from builders for installation of equipment of buildings, structures, foundations, openings and niches in the structures of buildings and structures is carried out; the installation of embedded parts is monitored, the presence of stationary crane beams, installation trolleys and hoists provided for by the project is checked.

At the third material and technical stage, electrical installation work is provided and completed with equipment, materials, products, and installation blanks; At the same stage, installation work is equipped with mechanisms, tools, equipment and safety equipment.

An important point organization of electrical installation work at complex facilities that require a certain order of execution of construction and electrical installation work is the preparation of PPER. This project 1 is necessarily developed for electrical installation work, accompanied by complex rigging work using mechanisms (truck cranes, aerial platforms), steeplejack work, as well as for work performed in existing electrical installations, for example, during the reconstruction of existing substations.

PPER is developed by special pre-production groups of installation organizations and approved by technical manager(chief engineer). PPER must be agreed upon with the customer or the technical manager of the operating organization.

The initial data for the development of PPER are:

working drawings and estimates of project documentation for the facility:

data on the supply of equipment and materials, the availability of machinery and mechanisms;

current regulatory documents, installation instructions, industry rules on labor protection;

timing of possible shutdown of existing electrical installations during reconstruction and technical re-equipment objects.

The second section of the PPER provides the most effective methods organization and technology of electrical installation work. It indicates technological methods for performing labor-intensive operations, their mechanization, proposals for combining installation and commissioning work, instructions on labor protection, and work schedules are provided.

The third section of G1PER includes tasks directly for electrical installation personnel indicating the responsible engineering and technical workers for the stages of work, lists of assemblies, blocks and structures to be assembled, necessary drawings or links to standard albums, lists of embedded parts, their sketches and installation locations, specifications for equipment and materials for the work.

Electrical installation planning

Planning is one of the main functions of managing the process of construction work, including electrical installation work. One of the planning tasks is to find options, a rational relationship between the stages of electrical installation work. An important point in planning is the mutual coordination of work over time, subject to the continuity of their implementation, especially when carrying out work in existing electrical installations.

The simplest form of work planning is the preparation of a work schedule, which is a document regulating the timely delivery of equipment and components, the need for mechanisms, machinery, labor and energy resources, the distribution of capital investments and the volume of electrical installation work.

Linear work schedules are conservative in their execution and reflect only one possible situation in the progress of work. If deviations arise in time and in the relationship between production factors, this model must be adjusted or rebuilt.

When planning electrical installation work, network models are used, the main elements of which are network diagrams. The development of a network schedule begins with establishing a list of works that need to be performed, determining their duration, rational technological sequence and the relationships between them.

The main components of a network schedule are events and activities. Each work reflected in the schedule has its own duration: deterministic, established by time standards, or probabilistic, established, for example, on the basis of statistical data. The work may be fictitious, not requiring time, but indicating the possibility of starting this work only after the completion of another (installation of a transformer is possible only after the reinforced concrete foundation has hardened).

An event represents the completion of one or more activities, creating the opportunity for other activities to begin. In the network diagram (Fig. 1.1), events are depicted as a circle divided into sectors. The upper sector indicates the event number, the left indicates the earliest possible timing of the event, in the right - the latest of the permissible dates for the event.

On the network diagram work i-j is depicted by an arrow connecting two events - the previous / and the subsequent / (solid arrow - real work; dotted - fictitious work). The direction of the arrow shows the order in which the work is performed; The operating duration t is indicated by the number next to the arrow.

Rice. 1. Network schedule for installation of a 10/0.4 kV substation: 1-2 - installation of substation lighting, t = 3 days; 2-3 - installation of switchboard panels (distribution, control, metering), 8 days; 2-4 - inspection, installation and adjustment power transformers, 6 days; 2-5 - installation of 10 kV switchgear, 8 days; 3-5 - fictitious work.

Laying control cables and power cables 0.4 kV, 10 days; 4-8 - input of 10 kV cables to transformers, 4 days; 5-7 - input and cutting of cables in 10 kV switchgear chambers, 6 days; 6-7 - cutting and connecting cables to 0.4 kV switchboards, 3 days; 6-11 - checking the circuit, adjusting equipment, adjusting 0.4 kV switchboard panels, 7 days; 7-8

Fictitious work; 7-11 - adjustment of 10 kV switchgear circuits. 6 days; 8-9 - phasing of 10 kV cables in transformer chambers, 1 day; 9-10 - cutting and connecting 10 kV cables to transformers, 2 days; 9-11 - binding of external cable routes, making inscriptions on the walls and doors of the substation, 1 day; 10-11 high-voltage tests of cables and transformers, 1 day.

The chain of sequential activities connecting the initial (1) and final (11) events is called the complete path of the network diagram. The complete path with the longest duration is called the critical path. In accordance with Fig. 1 critical path is 30 days. In relation to the critical path, all other paths in the network diagram have a reserve of time.

Typically, the development and analysis of network models is carried out in two stages. At the first stage, a network diagram is built and all its parameters are calculated, at the second stage, the network diagram is analyzed, adjusted and optimized.

The process of optimizing a network schedule in time consists, first of all, in reducing the duration of the critical path. There are three optimization methods here. The first method is to adjust the network schedule in such a way that it is possible to reduce the duration of activities on the critical path due to resources (labor and material) allocated for activities that are not on the critical path. These works may be postponed for some time, since their completion dates do not affect the final deadline.

The second time optimization method is to change the topology of the graph network. This is done by introducing multivariate technology for performing work into the network model, establishing new paths and interconnections of work, and ultimately reducing the critical path.

The third method of time optimization is associated with the division of long-term work into separate parallel work.

In general, the network planning system allows you to visualize and evaluate the organization of electrical installation work, and carry out more informed planning and operational management of these works.

Prepareforging for electrical installation work

Before starting electrical installation work at the site, the following activities must be completed:

1 the contractor received design and technical documentation approved by the customer’s stamp “for work”;

2 the equipment delivery schedule has been agreed upon between the contractor and the supplier companies, taking into account the technological sequence of the work. A list of complex electrical equipment installed with the assistance of the chief installation personnel of supplier companies, conditions for transportation to the installation site of heavy and large electrical equipment;

3 premises have been prepared to accommodate teams of workers, engineering and technical workers, a production base, as well as for storing materials and tools;

4, according to the act, the construction part of the facility was accepted for installation of electrical equipment and the measures provided for by the norms and rules for labor protection, fire safety, and environmental protection were carried out.

When accepting equipment for installation, it is inspected, completeness is checked (without disassembly), and the availability and validity period of manufacturer’s warranties are checked. The results of the inspection are documented in a corresponding document.

During installation, electrical equipment is not subject to opening or inspection, except in cases where this is provided for by state and industry standards or technical specifications, and also in cases long-term storage equipment in violation of factory instructions. Disassembly of equipment received sealed from the manufacturer is prohibited.

Deformed and damaged electrical equipment must be installed only after damage and defects have been eliminated.

Electrical equipment that has expired regulatory period storage specified in state standards or technical conditions, is accepted for installation only after a pre-installation inspection, correction of defects and testing. The results of the work performed must be entered into forms, passports and other accompanying documentation for the equipment, and an act on the implementation of the specified work must be drawn up. Premises closed distribution devices, foundations for electrical equipment are handed over for installation with fully completed construction and finishing works. The delivery and acceptance of premises and foundations for the installation of complex and expensive electrical equipment, the installation of which will be carried out with the assistance of installation supervisors, is carried out jointly with representatives of the company carrying out installation supervision.

Before starting electrical installation work, for example, on open switchgears, the general contractor must complete the planning of the territory, the construction of access roads, cable channels, install busbars and linear portals, build foundations for electrical equipment, and fences around the switchgear.

In the structures of portals and foundations for switchgear equipment, the embedded parts and fasteners provided for by the design, necessary for fastening strings of insulators and equipment, must be installed. Cable ducts and tunnels must have embedded parts for fastening cable structures. The construction of the water supply system and those provided for in the project must also be completed. automatic devices fire extinguishing

In buildings and structures handed over for the installation of electrical equipment, the general contractor or direct construction contractor must make the permanent openings, niches, openings in walls and ceilings required for moving electrical equipment and installing low-voltage electrical networks and control cables provided for in architectural and construction drawings. After performing electrical installation work, the general contractor is obliged to seal temporary holes, grooves, niches and sockets.

Labor protection when performing electrical installation work

An important point in organizing electrical installation work is the preparation and provision safe conditions labor. All preparatory activities in this regard, must be completed before the start of work and accepted according to the act of fulfilling labor protection requirements.

Responsibilities for ensuring safe working conditions are assigned to the contractor, who develops organizational and technological documentation for the execution of work (PPED), containing specific design solutions that define the technical means and methods of work that ensure execution regulatory requirements labor protection.

The initial data for developing such solutions are:

requirements regulatory documents and labor safety standards;

standard solutions for ensuring labor safety requirements, reference manuals and catalogs of protective equipment for workers;

instructions from manufacturers of machines, mechanisms, equipment, materials and structures to ensure labor safety during their use.

During development design solutions in organizing installation sites, it is necessary to identify hazardous production factors associated with the technology and conditions of work, determine and indicate in the organizational and technical documentation the zones of their action.

Electrical installation work can be associated both with the construction of new facilities (new substations, power lines) and with the reconstruction of existing ones. In the second case, electrical installation work refers to work performed in existing electrical installations. Here, areas with hazardous production factors include all work near live parts of an operating electrical installation. To carry out such work, a work permit must be issued; when performing work, technical and organizational measures without danger must be observed. These measures must also be carried out when working in compressor rooms, with air collectors, and using gas cylinders during gas welding work.

Electrical installation work in existing electrical installations, as a rule, should be carried out after removing the voltage from all current-carrying parts located in the work area, disconnecting them from the active part of the electrical installation and ensuring visible breaks electrical circuit and grounding of disconnected live parts. The work area must be separated from the active part of the electrical installation by a solid or mesh fence that prevents installation personnel from entering this part, and safety posters must be posted.

The allocation of a work area for the installation organization, the adoption of measures to prevent the erroneous supply of voltage to it, the fencing from the operating part, indicating the places of passage of personnel and the passage of machinery, must be documented in an approval certificate.

The admission of electricians to work in existing electrical installations must be carried out by the personnel of the operating organization and is documented in in writing indicating the composition of the team and the electrical safety group for each team member. The work permit is issued to the work manager (foreman, foreman, manager) for the period necessary to complete the specified amount of work. Before being allowed to work in existing electrical installations, personnel of electrical installation organizations must be instructed on issues of electrical safety in the workplace by the person allowing them to work, who is obliged to monitor the implementation of the measures provided for in the permit to ensure the safety of work.

Operating personnel are responsible for maintaining temporary workplace fencing, warning posters and preventing the supply of operating voltage to disconnected live parts, and maintaining safe distances for members of the installation team to live parts that remain energized.

The work of the electrical installation team must be supervised by a competent and experienced engineer and technical worker. contractor, which must correctly arrange people and mechanisms, ensure that the requirements of the operating personnel are met.

Important elements of high quality and safety of work are appropriate qualifications and high discipline of electrical installation and operational personnel; in the absence of these qualities, even the most carefully developed PPERs do not guarantee against industrial injuries, defects during the installation of expensive equipment, supplying voltage to the work area.

Electrical installation work is accompanied by the widespread use of various construction machines and mechanisms (transport, lifting, earth-moving and others). All machines and mechanisms must comply with the requirements of state labor safety standards (have a certificate of compliance with safety requirements). Engineering and technical workers responsible for the execution of work and workers performing rigging or rafter work must be certified by state supervisory authorities.

When placing machines on the installation site, the work manager must determine the working area of the machine and the boundaries of the dangerous zone it creates. At the same time, visibility must be ensured working area from the driver's workplace.

Vehicles and equipment used for loading and unloading operations must be appropriate to the nature of the cargo being processed. Areas for loading and unloading operations must be planned and have a slope of no more than 5°, and their dimensions and coatings must comply with the PPER.

For cramped and dangerous work conditions, the reach and angle of rotation of the lifting vehicle's boom must be regulated, and when working in a security zone, power lines of machines (except for crawler machines) must be grounded using an inventory of portable grounding.

Carrying out work in the security zone of the line is permitted provided that the air distance from the machine (mechanism) or from its retractable or lifting part to the nearest live wire is not less than:

1.0 m - with line voltage up to 35 kV;

1.5 m - with a line voltage of 110 kV.

2.5 m - with a line voltage of 220 kV.

Technical condition of all Vehicle must comply with the Traffic Rules and the Labor Safety Rules in road transport.

Carrying out certain types of work at the installation site, for example welding, gas-flame, electrothermal, must be carried out in accordance with inter-industry rules on labor protection when performing these works. These works include, in particular, installation soft roof on the roof of a closed switchgear using gas burners, warming up power transformers before testing them after installation and other work.

In these cases, fire prevention measures must be taken, and in some cases, the contractor or customer, at the request of the electrical installation organization, must notify the local fire department to supervise fire-hazardous work.

Industrialization and mechanization of electrical installation work

In order to reduce the time it takes to put objects into operation and improve the quality of electrical installation work, we strive for maximum industrialization and mechanization of these works, as well as to attract highly qualified personnel from manufacturing enterprises for the installation of electrical equipment.

Industrialization refers to the pre-packaging and assembly of electrical equipment in order to increase its installation readiness. This is achieved by transferring the maximum possible number of operations for the installation of electrical installation elements from the installation area to assembly plants and workshops equipped with highly productive mechanisms.

The level of industrialization is determined by the ratio of the volume of electrical installation work performed outside the installation area to the total volume of electrical installation work.

To increase the level of industrialization of work. Large installation organizations, as a rule, have divisions engaged in the manufacture of products, structures and mechanisms that are not mass-produced by industry.

Industrial installation consists of two stages:

the first stage includes the preliminary configuration of electrical equipment, assembly at factories and installation workshops of the supplied isolated equipment into complete units and enlarged units, bringing them to full installation readiness;

at the second stage, complete units and enlarged equipment units are installed, power and lighting networks and grounding networks are laid, installation is checked for correctness, commissioning and acceptance tests of electrical equipment are carried out.

Most high level industrialization includes work on the installation of switchgears, the manufacture of which in the form of complete cells and blocks is carried out at domestic industrial plants: KRU-6/10, KRUB-35, KRUB-110, KRUE-110 kV and higher.

The development of industrial methods of electrical installation work is closely related to an increase in the level of their mechanization. Mechanization of electrical installation work has two main directions:

the use of universal mechanisms and lifting and transport machines to mechanize labor-intensive processes; these are, in particular, drilling and crane machines, telescopic towers, hydraulic lifts;

the use of general construction tools, the development and use of various devices when performing individual installation operations; these are, in particular, various power tools, construction and assembly guns, portable presses for terminating and connecting wires and cable cores.

Meeting the deadlines for putting objects into operation significantly depends on the logistics of electrical installation work. In the structure of large installation organizations, the functions of material and technical support are assigned to special units - departments (sections) of production and technical equipment (UGGGC).

These structural units delivered to the installation area using their own resources and means. necessary equipment, materials and mechanisms. The successful operation of departments requires the mechanization of warehousing facilities, which makes it possible to mechanize the assembly of materials and products into special containers for their subsequent delivery to the installation area.

Installation of complex and expensive equipment (powerful transformers, new circuit breakers at PO kV and higher, electrical equipment from Siemens, ABB and others) is usually carried out with the assistance of installation supervisors from the equipment supplier. These personnel, in accordance with the equipment supply agreement, supervise the installation and testing of equipment.

Commissioning works

Commissioning work accompanying electrical installation work is a set of works that includes checking, adjusting and testing electrical equipment in order to ensure its design parameters and modes.

Commissioning work is carried out in four stages.

N and in the first (preparatory) stage the contractor:

develops (based on design and operational documentation manufacturers) work program commissioning works, including labor protection measures;

transmits to the customer comments on the project identified during the development of the work program;

prepares a fleet of measuring equipment, testing equipment and devices.

At this stage of work the customer:

issues to the contractor installations of relay protection, interlocks and automation, coordinated with the power system;

supplies voltage to the workstations of commissioning personnel from temporary or permanent networks electricity supply;

appoints representatives for acceptance of commissioning works and agrees with the contractor on the deadlines for completing the work, taken into account in general schedule construction.

At the second stage, adjustment work is carried out separately standing panels control, protection and automation, as well as adjustment work combined with electrical installation work. The start of commissioning work is determined by the degree of readiness of construction and installation work: in electrical rooms All construction work must be completed, including finishing, all openings, wells and cable channels must be closed, lighting, heating and ventilation must be completed, the installation of electrical equipment must be completed and its grounding must be completed.

At this stage, the general contractor provides temporary power supply and temporary communications in the work area.

The customer provides:

agreement with design organization questions regarding comments identified during the study of the project;

replacement of rejected electrical equipment and supply of missing electrical equipment, elimination of electrical equipment and installation defects identified during the commissioning process:

electrical testing and repair measuring instruments.

At the end of the second stage of commissioning and before the start of individual tests, the contractor makes changes to the electrical circuit diagrams of power supply facilities that are switched on.

At the third stage of commissioning, individual testing of electrical equipment is carried out, in particular, checking and testing cooling systems and RIN of transformers, protection devices, automation and equipment control. Especially with new relays from Siemens and ABB.

The beginning this stage introduction is considered operating mode at this electrical installation, after which commissioning work must relate to work in existing electrical installations and be carried out with the issuance of a work permit and compliance with technical and organizational measures security.

At this stage, individual tests of the equipment are carried out, setting parameters, protection settings and equipment characteristics, testing control, protection and alarm circuits, as well as testing electrical equipment on Idling.

Maintenance of electrical equipment at this stage is carried out by the customer, who ensures the placement of operating personnel, assembly and disassembly of electrical circuits, and also carries out technical supervision of the condition of electrical equipment.

After completion of individual tests, the electrical equipment is considered accepted for operation. In this case, the contractor transfers electrical equipment test reports to the customer. increased voltage, testing of grounding and grounding devices, as well as executive and circuit diagrams necessary for the operation of electrical equipment. All other protocols for setting up electrical equipment are transferred to the customer within four months after the facility is accepted into operation

The completion of commissioning work at the third stage is formalized by a certificate of technical readiness of electrical equipment for comprehensive testing.

At the fourth stage of commissioning work, a comprehensive testing of electrical equipment is carried out according to approved programs. At this stage, commissioning work is carried out to set up the interaction of electrical equipment systems in various modes.

The scope of these works includes:

security mutual relations, adjusting and customizing the characteristics and parameters of individual devices and functional groups electrical installations in order to ensure specified operating modes;

electrical installation testing full scheme at idle and under load in all operating modes to prepare for comprehensive testing technological equipment.

Commissioning work at the fourth stage is considered completed after the electrical equipment has received the parameters and modes provided for by the design, ensuring a stable technological process. For power transformers this is 72 hours of operation under load, for air and cable lines power transmission - 24 hours of operation under load.

Acceptance of the facility into operation

During the construction of a facility (power lines, substations), technical supervision is carried out over the construction, installation and commissioning work. This supervision is provided by future operating personnel (customer), design organization (author's supervision), state supervision bodies, in particular, Gosgortekhnadzor.

The latter is a federal executive body that carries out regulatory regulation, permitting, control and supervisory functions in the field of industrial safety, use and protection of subsoil.

The task of the operational personnel at this stage is to assist the installation organization in terms of timely identification of defects, omissions and deviations from the project.

Upon completion of all work, the contractor notifies the customer of the need to accept the facility into operation.

The facility presented for acceptance into operation must comply with legal requirements Russian Federation, design documentation, construction agreement (contract), sanitary, environmental and other standards. The assessment of the facility’s compliance with the project and the requirements of regulatory documents is carried out by an acceptance committee, which includes representatives of the customer, the design contractor, territorial administrations, state supervisory authorities and labor safety inspectorates.

The customer presents to the acceptance committee all the necessary design and technical documentation for the facility.

To assist the acceptance committee, a working commission is created, the members of which carry out a detailed inspection of the object and draw up reports listing the detected defects and deficiencies in individual sections of the project or in the entire object.

After the contractor has eliminated all the shortcomings and inconsistencies with the project indicated by the working commission, an acceptance certificate for the completed construction of the facility is drawn up (Form N KS-11). In practice, this act is called the “act of the working commission”. This document is the basis for final payment for all work performed by the contractor in accordance with the work agreement (contract).

Based on the act of the working commission, familiarization with technical documentation positive results Carrying out individual and complex tests, the acceptance committee determines the readiness of the facility for commissioning.

The final document for the acceptance and commissioning of a completed construction facility is the acceptance certificate of the completed construction facility by the acceptance committee (Form N KS-14). This act is signed by all members of the acceptance committee, each of whom is responsible for the decisions made by the commission within the limits of their competence.

The acceptance committee resigns its powers after approval of the acceptance committee act by the customer. From this moment, the object passes into the jurisdiction of the operating organization (customer), which accepts its balance and registers the ownership of the new object in the prescribed manner with local executive authorities.

Posted on Allbest.ru

...Similar documents

Determination of the physical volumes of electrical installation work, selection of installation machines, mechanisms, apparatus, tools and devices. Characteristics of complete installation transformer substation, distribution devices and switching devices.

course work, added 12/26/2011

Initial data and specifications machine; development electrical diagram. Calculation of power of electric motors of drives. Justification for the choice of electrical control devices and starting protection equipment. Installation and adjustment of electrical equipment of the machine.

course work, added 08/23/2013

Schematic diagram and the principle of operation of the car dumper device. Technical regulations for the safe performance of work on unloading coal on a car dumper. General rules and ensuring electrical safety when performing work. Occupational Safety and Health.

course work, added 09/11/2010

Characteristics and parameters of the mounted object. Requirements for organizing the installation site. Preparation for installation work. Test standards for polyethylene gas pipelines. Selection of construction machines for work. Calculation of labor costs.

course work, added 04/24/2015

Preparation rocks for excavation at the Zhegolevsky quarry: organization of the production process, mechanization of excavation and loading operations, movement of rock mass, dumping. Calculation and selection of technological equipment, maintenance and repair.

thesis, added 11/22/2010

Basic automation solutions. Determination of the scope of work and calculation of volumes. Determination of the labor intensity of work and the need for material and technical resources. Calculation of the industrialization coefficient of installation work. Network planning of installation work.

course work, added 02/10/2015

Mechanization of loading and unloading operations at an explosives warehouse. Mechanization of loading wells in open-pit mining. Mechanization of loading holes (wells) during tunneling. Safety precautions when mechanizing blasting operations.

abstract, added 08/26/2011

Preparatory work for repairs. Methods for cleaning tanks. Repair of bases and foundations. Removal of defective areas without welding. Quality control repair work and tank testing. Acceptance of tanks after repair.

test, added 12/12/2010

Calculation of the volume of preparatory and cutting work. Number of workers, tunneling equipment and production standards. Network schedule of mining preparatory work and block development. Parameters of well breaking and organization of labor in the production face.

course work, added 07/18/2011

Cleaning the surface from dirt, oil and grease. Removal of corrosion products and scale, dust and abrasive residues. Carrying out painting works. Performing welding and repair work. Quality control paint coating and acceptance of work.

(4293.8 kb.)

Available files (14):

| .DS_Store | |||

| For lecture No. 3 Thermal imaging inspection.pptx | |||

| Lecture No. 1 Organization of operation (4 hours).doc | 668kb. | 06.03.2007 17:59 | |

| Lecture No. 2 Switching order in electrical installations (2 hours).odt | |||

| Lecture No. 3 Thermal imaging examination (2 hours).docx | 294kb. | 18.11.2008 18:33 | |

| Lecture No. 4 Procedure for carrying out work with increased danger (2 hours).doc | 86kb. | 14.04.2009 01:23 | |

| 280kb. | 23.03.2010 01:57 | ||

| Lecture No. 6 Electrical safety (2 hours).doc | 141kb. | 17.05.2010 07:51 | |

| Lecture No. 7 Neutral modes up to 1000V, RCD (2 hours).docx | 55kb. | 06.04.2010 02:58 | |

| Part II Lecture No. 1 (Operation of Generators).docx | 282kb. | 08.09.2010 00:32 | |

| Part II Lecture No. 2 (Operation of EO RP).doc | 106kb. | 29.09.2010 08:55 | |

| Part II Lecture No. 3 (Operation of overhead power lines).doc | 94kb. | 26.10.2010 21:31 | |

| Part II Lecture No. 4 (Operation of cable power lines).doc | 146kb. | 03.11.2010 07:10 | |

| Part II Lecture No. 5 (Operation of power transformers, Part 1).doc | 473kb. | 09.11.2010 21:06 |

Lecture No. 5 Organization of electrical installation production (2 hours).doc

ORGANIZATION OF ELECTRICAL INSTALLATION PRODUCTION1 Types of electrical installation work and structure of electrical installation organizations

Electrical installation is distinguished by a wide variety of types of work performed. This can be judged by the volume of current standards and prices that exist for all types of work. The unified standards and prices for settlements with workers (ENIR) for electrical installation contain more than 600 items, and the unified price list for the installation of electrical equipment and electrical networks contains more than 4,000 consolidated prices.

Electrical installation work applies to the following types of installations: overhead power lines (OHL); external cable networks; switchgears and substations; internal electrical wiring; Power equipment; lighting electrical equipment; automatic and control instruments. Besides, special types works extend to batteries, capacitor banks, heavy tires, large electrical machines.

Workers are divided into specialties according to the types of electrical installation work, namely: electricians for power equipment, lighting networks, switchgears and substations, air lines power transmission (linemen), etc.

Commissioning work is usually carried out by a specialized commissioning department. The assembly trusts have independent (on their own balance sheet) mechanization and road transport, as well as management of production and technological equipment (UPTK). The task of the UPTK is to centrally supply all the necessary material and technical resources for the installed objects, with their delivery by containers to the installation area.

The installation department includes a production preparation area (PPP) and an electrical installation workshop (EPW). The tasks of the UPP and MEZ are to perform the maximum possible amount of preparatory and installation work outside the installation area, sometimes long before the completion of construction work and the start of installation.

^

2 Design and installation documentation and estimates

Design is carried out in one and two stages. For objects whose construction is carried out according to standard and reused designs, as well as for technically simple objects, design is carried out in one stage - a detailed design with a consolidated cost estimate. For other objects, design is carried out in two stages:

1) a project with a summary cost estimate;

2) working drawings and estimates.

In addition to design documentation, installation work may require documentation from supplier factories - passports, instructions, etc.

The estimated cost of electrical installation work is divided into two main parts:

direct costs: main wage workers, the cost of materials, structures, including the costs of their transportation to the on-site warehouse of the installation organization, and costs associated with operation mounting mechanisms and equipment;

overhead costs: administrative and economic costs, expenses for servicing workers (additional wages, deductions but social insurance, expenses for sanitary services, labor protection, contributions to trade unions for cultural work, etc.), for the maintenance of fire and security guards, improvement and maintenance of installation sites, for industrial trips. Overhead costs are a certain percentage of the basic wages of workers or the amount of direct costs.

An electrical installation project (EPW) is being developed by the site engineering training production (UIPP) on the basis of working drawings and estimates issued by the electrical installation organization. It includes the following sections: general scope of work on the facility, broken down into installation zones and stages; labor intensity of work and wage fund separately for linear installation sites and oil extraction plants; work schedules (including network ones), agreed upon with related organizations (plumbing, mechanical installation, etc.) and linked to the deadline for putting the facility into operation; number of workers by qualifications and traffic schedule; the need for workshops, warehouses, storerooms, sheds and their placement; list of orders to be carried out in workshops for electrical installation workpieces, indicating cost and labor intensity; transportation and rigging of enlarged assembly units and equipment; technological standards for special and complex types installation work; safety measures.

Economic evaluation may be necessary when developing PPERs. various options method and sequence of work.

The automated control system (ACS) for enterprises and construction and installation works is an advanced scientific organization of construction management, which is increasingly being introduced into production. The main element of the automated control system is a network schedule that establishes the relationship and sequence of all technological operations for the creation of a new facility, including the receipt of design documentation, the supply of materials and equipment, and the delivery of the necessary mechanisms. The duration of work in a network schedule is determined by labor cost standards and represents labor-intensive calculations performed using electronic computers.

Network diagrams can be complex (for all types of work during the construction of a facility) and local (for certain types of work, including electrical installations). In Fig. 1.1 shows an example of a local network schedule with a total duration of work of 100 days.

ABOUT

The main components of the network schedule are events and activities. Events are represented by circles and represent the completion of one or more activities, while simultaneously creating the opportunity for the start of other activities. The work is represented by an arrow connecting two events - the preceding and the subsequent. The direction of the arrow shows the order of work; The numbers above the arrow indicate the duration of operation (usually in days). The numbers in the circles mean: in the numerator - the code number of the event, in the denominator - the duration of work from the beginning to the completion of this event. The work may be valid(solid arrow), i.e. requiring a certain amount of time to complete, and fictitious(dashed arrow), which does not require time, but indicates the possibility of starting this work only after completing another (for example, laying a cable can begin only after completing digging a trench).

The network diagram is characterized in a critical way which is understood as a continuous sequence of works and events from the initial to the final event. To overcome the critical path it is required longest time. In other words, this is the path that has the longest duration. Events and activities lying on the critical path are called critical. The main task of calculations using a network diagram is to determine the critical path, i.e. the total duration of the planned set of works, allowing in each specific case to identify those works on which the duration of the entire construction depends. On the graph (Fig. 1.1) the critical path is marked with thick arrows.

During construction, it can be carried out network diagram optimization but time. This is a reduction in the duration of work on the critical path due to resources (labor and material) allocated for work not on the critical path, which can be postponed for some time, since the timing of their completion does not affect the final construction period.

^

3 Industrialization, mechanization and logistics support for electrical installation work

Industrialization and mechanization. Industrialization is the main direction of technical progress, helping to reduce the time of work, reduce their cost and accelerate the commissioning of facilities. Industrialization electrical installation production is the maximum transfer of electrical installation work outside the installation site (to factories and electrical installation workshops), where the labor of workers is more productive, inherent in organized industrial production.

^ Level of industrialization is determined by the ratio of the volume of electrical installation work performed outside the installation area to the total volume of electrical installation work. The increase in the level of industrialization is facilitated by: the development of production by electrical industry factories that produce complete and large-block elements of electrical installations; organizing the work of the oil extraction plant for the procurement of materials and equipment; production and assembly of enlarged electrical installation assemblies, as well as expansion by factories of the production of mounting products and mechanisms that reduce the labor intensity of work in the installation area.

The highest level of industrialization is associated with the installation of switchgears and substations, the production of which in the form of complete devices is carried out at electrical industry factories and installation organizations.

Busbars are produced: main - alternating current up to 4 kA and direct current up to 6.3 kA; distribution - up to 0.63 kL for lighting mains and trolley lines.

The use of busbar trunking creates universal electrical networks that allow quickly and efficiently minimal costs connect shop equipment to them when the production process changes and the associated rearrangement and replacement of machines and machines, and also eliminates the need to lay bulky and expensive cable and pipe electrical networks.

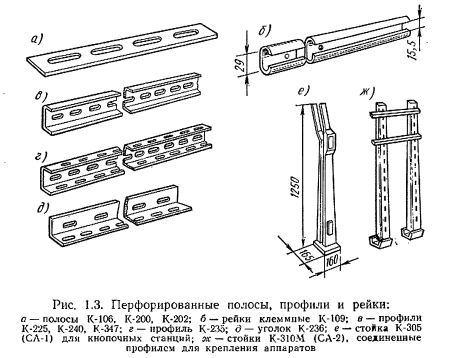

In Fig. Figure 1.2 shows the placement inside the workshop of a complete transformer substation with main and distribution busbars connected to it. Perforated strips, profiles and racks (Fig. 1.3), produced by factories of installation organizations, free installers from labor-intensive work on the manufacture of fastening structures. Different kinds dowels allow you to fasten electrical wiring and electrical structures with minimal labor costs. The production of assembly products from polymer materials.

To increase the industrialization of electrical installation work, it is important to properly organize and equip central workshops for electrical installation workpieces. The main direction in this area is the maximum transfer of assembly and procurement operations to production production lines. Currently, workshops for electrical installation workpieces widely use production lines of machines for processing and assembling pipes into enlarged blocks, for assembling magnetic stations and other equipment elements into enlarged blocks, for processing heavy copper and aluminum busbars, and for preliminary preparation of finished units internal electrical wiring, cable lines, installation of overhead crane cabins and preparation of enlarged trolley units, etc.

Most of the special mechanisms and devices for completing the production lines of the MEZ are manufactured at the plants of the installation organizations.

The development of industrial installation methods is closely related to the increasing level of mechanization. The introduction of mechanization of electrical installation work has two main directions:

the use of universal mechanisms and lifting and transport machines (pit drills, pillar drills, aerial platforms and hydraulic lifts, machines and mechanisms for processing sheet and profile rolled steel, as well as spikes made of copper and aluminum, etc.) for the mechanization of labor-intensive processes;

the use of tools and various devices (power tools, pyrotechnic tools, lifting and loading winches, devices for connecting and terminating wires and cables, etc.) that increase labor productivity in individual installation operations, i.e., the introduction of so-called small-scale mechanization.

The main part of the equipment, cable products, and installation products is delivered to the workshops of electrical installation parts for processing, packaging and assembly of enlarged installation units. Some of the equipment and materials are supplied directly to the installation area and do not require pre-processing in workshops or assembly.

In the structure of installation trusts, to ensure material and technical supply, there is a UPTK in installation departments - kitting groups as part of the UPP.

For successful work assembly areas, which, with their own resources and resources, deliver to the installation area all the necessary equipment, containers with materials and workshop products for electrical installation workpieces, well-established production preparation is required, as well as mechanization of warehouse facilities.

The modern mechanized warehouse of the assembly department is equipped with stacks and cranes that allow the mechanized assembly of materials and products into containers for delivery to the installation area.

^

4 Planning electrical work

In construction and installation production, the following stages of planning are distinguished: drawing up long-term plans for five, ten years; approval of annual plans broken down by quarter; Adoption operational plans on short periods time (month, week); drawing up calendar plans for the entire period of work on the facility, taking into account the work of all construction, installation and supply organizations involved in the construction of the facility.

The organization's activities are assessed according to three indicators: 1) implementation of the plan for putting facilities into operation; 2) implementation of the plan for the volume of construction and installation work at facilities completed in the planned year; 3) obtaining balance sheet profit.

An important economic factor of the enterprise is the observance of faster growth rates of labor productivity in relation to the growth rate of average wages of all personnel employed in production (workers, engineers and employees), including the payment of bonuses from the material incentive fund.

Planning of the installation organization is carried out in cost and physical terms. When planning electrical installation work, only cost indicators are used; when planning implementation new technology(chambers of switchgears, complete substations, etc.) - natural indicators.

The scope of electrical installation work includes wages with overhead costs and the cost of materials and structures according to established lists (the cost of equipment is not included, but it is included in the volume of general capital investments).

Estimates for construction and installation work are compiled based on prices of materials and tariffs, guided by norms and prices, taking into account the increase in tariff rates for workers. Preparation of estimates is time-consuming work; The main direction in this area is the creation of aggregated indicators of estimated costs by type of work.

All installation departments with an annual volume of work exceeding a certain amount are required to develop building financial plan(Stroyfinplan), representing an expanded program.

Operational planning includes drawing up and monitoring monthly work plans for sites, departments and trusts.

All installation organizations have constantly replenished means of production (machines, machine tools, mechanisms, industrial buildings, materials, structures, etc.), i.e. production assets - fixed and working capital.

^ Basic production assets ‒ these are means of production that do not change their natural form (machines, mechanisms, buildings, etc.) and transfer their value to the final product gradually, as they wear out (depreciation). They are created and replenished through capital investments and special enterprise funds.

^ Working production assets ‒ these are materials (metal, cables, wires, etc.) that do not retain their natural shape and the full cost is transferred to the cost of completed work. They are made up of the cost of inventories of materials that are constantly in motion (expenditure and replenishment), as well as Money available on settlement and current accounts of banks and at the cash desk of the enterprise.

With time-based bonus payment, the worker receives an additional payment - a bonus for high-quality and timely completion of tasks in the absence of accidents and downtime of the equipment being serviced, and also provided that the site of the foreman or foreman served by him has met the monthly plan indicators.

Everywhere, a new advanced form of brigade economic calculation (according to the method of N. A. Zlobin) is being introduced into the practice of electrical installation work. At the same time, the team becomes an independent production and operational-economic unit, has contractual obligations and, in addition to the lump-sum payment received, receives additional bonuses: for reducing the standard time for a lump-sum task (at the expense of the salary fund); for commissioning of the construction project on time and ahead of schedule (at the expense of the customer); for the savings achieved by the team, obtained from reducing the cost of work performed (due to the savings achieved).

Labor productivity (output) is determined by the volume of installation work performed in rubles per worker (workers, office workers and engineers) for a certain period of time (year, month, day).

Electrical installation work various levels complexity is the main direction of the specialists of the company “INZh Service”. We have licenses and certificates to carry out this or that type of work. Many years of experience And modern equipment allow you to perform electrical installations efficiently and in the shortest possible time. Electrical installation work in Moscow is carried out using practical and affordable materials.

Electrical installation work includes installation of sockets, switches, ventilation and heating systems, lightning rods, replacement of electrical wiring, connection of security systems, television, telephone and Internet lines, laying power lines, installation and assembly of electrical panels and others. We will carry out electrical installation work for organizations and individuals. In addition, our competence includes commissioning of the electrical installation and its further maintenance.

We undertake both large-scale electrical installation work and minor repairs, for example - electrical wiring. Electrical installation often requires an individual approach. Before starting to solve the problem, our specialists will study the features of the room and do everything possible so as not to spoil the appearance of the room. For example, organizing electrical work in a house or apartment with interior decoration, in most cases, involves the use decorative electrical wiring. In this case, the cost of electrical installation work is completely justified, and the result exceeds all expectations.

Electrical installation from "INZh Service"

When ordering private electrical installation services, be prepared for unpleasant consequences: unsafe power supply, failures, short circuits, damage to electrical equipment, and so on. Often such electricians do not comply with GOST and SNiP standards at all, as a result of which, best case scenario, is a repeated request for electrical installation services, at worst - a danger to life and health, damage to property. It is worth understanding that when it comes to electricians, you should only contact a professional company that has permission to carry out the work.

ING Service specialists carry out turnkey electrical installation work, offering step-by-step planning with project development. As soon as the project is developed, we transfer it to the supervisory authorities for approval and adjustments. Next, we prepare necessary materials and equipment for the work and only after that we carry out electrical installation.

To understand the stages of electrical installation work, it is necessary to clearly understand the organizational process. After all, now it is difficult to imagine the fact that somewhere there is no electricity; this source of energy is simply necessary for humanity. During the construction of a facility, it is important to pay attention to electrical installation work.

Stages of work

The entire complex of actions is divided into four main stages. First of all, specialists prepare everything necessary for electrical installation work. If we consider this point in more detail, we highlight the following activities:

1. Drawing up technical documentation.

2. Coordination of work deadlines, schedule and delivery of devices. This section also discusses materials, products and manufacturing process. A list of electrical equipment and possible conditions transportation technical means to the place of work.

3. Providing separate premises for workers, engineers, managers. Under additional accessories warehouses must be allocated.

4. The project contains the following data: estimates, technical certificates and engineering developments.

5. Before electrical installation work, an act of the part of the building that is in the system is accepted. The document specifies existing safety standards and regulations, security conditions and much more.

The second stage of work includes two stages that must be completed efficiently and reliably. The first stage involves working inside the facility and installing support elements intended for installation of equipment. The cable is also laid, grounding is done and other network wires are created.

It is worth noting that the above actions must be performed simultaneously with construction work. At the second stage, engineers install the devices. To correctly install electrical equipment, specialists adjust the components and act strictly according to the rules.

Commissioning work is done at the third stage: the equipment mode is set, the system is checked, the control panel is configured, and tests are carried out. In general, workers perform four important activities:

1. First of all, it is necessary to develop technical documents for commissioning work. During the process, remarks or comments may be discovered, these need to be conveyed to the customer. It is necessary to prepare measuring instruments and other equipment for electrical installation work.

2. Then the created circuits are tested and the functions of the electrical equipment are checked. These actions can be carried out simultaneously with electrical installation work. In the second stage, construction work in technical areas, including grounding, ventilation and lighting, should also be completed.

3. The third stage indicates that the time has come individual checks electrical equipment. As a rule, the commissioning organization sets up the alarm system.

4. On the most last stage The device is checked using software. In other words, commissioning work is carried out in different modes to make a final conclusion on electric motors.

If the commissioning organization has positive recommendations, then the acceptance certificate is accepted.

After this, the complex of works will be checked again, submitted for testing and put into operation. Before the project is commissioned, a special commission is assembled, which includes experts, experienced managers and engineers. Typically, this commission is headed by a highly qualified specialist with the necessary skills.

The technical team checks the electrical installation work, fills out documentation and prepares a report. If defects or malfunctions are found during the inspection, the system is sent for revision. Only after inspection by the acceptance committee is the system put into operation.

Electrical installation organization will carry out the work you need in the field of electrification and commissioning of equipment in Moscow. The Yudu website will help you find the best company with the most reasonable prices. After reviewing the profiles posted on the platform, you will find many offers for the power supply of apartments, houses and cottages. Both companies and private electricians offer their services here, ready to come to your home in Moscow.

What services do electrical installation companies provide?

On the Yudu website you can quickly find a contractor for any type of work. Usually professional organizations provide the following types of services:

- construction of transformer substations

- construction and reconstruction of electrical substations and equipment

- laying power lines

- laying cables and wires in houses and apartments

- equipment grounding

- installation of various types of automation

All types of services are usually performed on a turnkey basis. Often companies also sell equipment and materials. All types of work are aimed at ensuring uninterrupted power supply to your apartment, cottage or house. In turn, this will protect your electrical devices from breakdowns.

What are the stages of electrical installation work?

The electrical installation company provides services not only for the electrification of buildings and structures, but also for ensuring their safety, including fire safety. All work is carried out in stages:

- an electrical installation organization prepares a work project, be it a simple repair or installation of new electrical equipment

- the project is checked for compliance with safety requirements

- craftsmen begin work

Major repairs in a cottage cannot be carried out without ordering the services of an electronics specialist and calling him to your home. New electrics, wires, sockets and switches cannot be installed by a person without the appropriate permission to work with electricity.

What does the project include?

You should agree on the design of the work with the craftsmen. It can be done both on paper and in in electronic format using modern programs 3D modeling. Please pay attention to the following nuances:

- the layout must reflect all the rooms of your apartment or house (hallways, bathrooms, balconies, storage rooms)

- Wires must be laid in such a way that the least amount of materials is spent

- sockets and switches should be located as conveniently and safely as possible - for example, if there are small children in the house, it is better to install these elements at a higher height

Having agreed on the project of work with the craftsmen, you can be sure that the rest will be done by professionals at the highest level.

On the Yudu website you can find average prices for the work indicated in the price lists, which will allow you to ask the price and choose the most profitable terms to conclude an agreement. You can also find out how much it costs to call a specialist to your home, what is the average price for services in the Moscow region, what it depends on, and how to get the discount that an electrical installation organization is ready to provide you with.