Today, it is simply impossible to imagine installing electrical wiring in an apartment or private house using wires without colored insulation. Wire color coding- this is not a pursuit of fashion or a marketing ploy by a manufacturer who wants to lure potential buyer with its colorful electrical products.

Differentiating electrical wires by color is an urgent need. Firstly, by the color scheme we can determine the purpose of each conductor located in a particular group of wires. Secondly, the likelihood of making a mistake during connection and connection is greatly reduced, and this will save the electrical wiring from a short circuit and injury to a person electric shock.

The color of the wire insulation is not chosen arbitrarily. There is a single color standard, clearly stated in the PUE (electrical installation rules). It says that all wire and cable cores must be identified by color or alphanumeric designations.

With the adoption of a unified standard for the color designation of electrical conductors, their installation has become much easier. Each core has a specific purpose and is designated by a unique color: black, white, yellow-green, blue, etc.

Most often isolation electric wire painted in color scheme along its entire length. But it is also possible to use colored heat-shrinkable tubes (cambrics) or colored electrical tape at the ends of the cores and at connection points.

Let's consider what color coding wires are used in single-phase, three-phase and direct current.

Wire colors in single-phase wiring

IN electrical networks alternating current Multicore wires with insulation of different colors are used, which makes it much easier installation work and eliminates connection errors.

Let's find out what colors the conductors have in AC electrical installations with voltages up to 1000V and with a solidly grounded neutral (most administrative buildings and all residential buildings).

Color of zero protective and zero working conductors

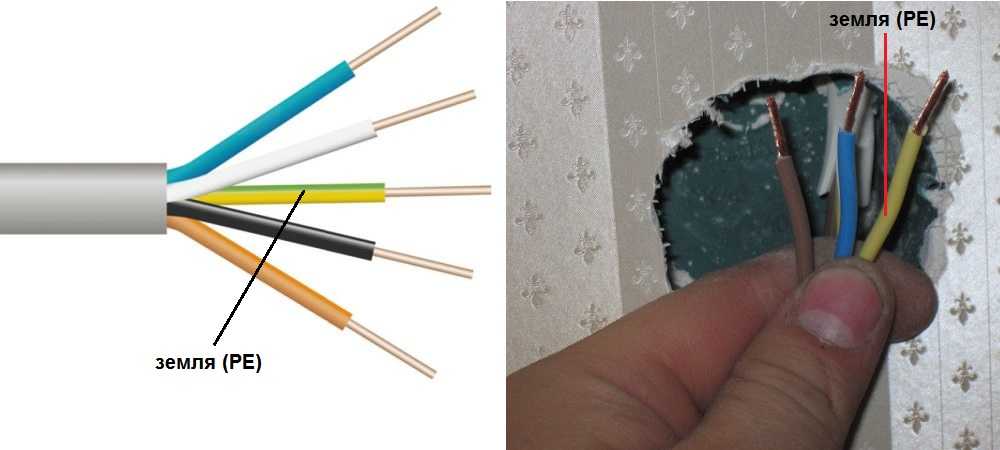

The neutral working conductor (N) should always be blue. Null protective conductor(PE) -colored in yellow-green longitudinal or transverse stripes. Wires with this color combination should only be used for their intended purpose!

The combined zero working and zero protective (PEN) wire has Blue colour along the entire length of the conductor with yellow-green stripes at the ends. GOST also allows the opposite option - yellow-green stripes along the entire length with blue at the ends.

So, neutral wires by color:

Zero worker (N) - blue color;

. zero protective (PE) - yellow- green color;

. combined (PEN) - yellow-green with blue marks at the ends (or vice versa).

Phase wire color

Phase wires in electrical wiring, according to the recommendations of the PUE, should have the following colors: black, brown, red, gray, purple, pink, white, orange and turquoise.

Phase wires in electrical wiring, according to the recommendations of the PUE, should have the following colors: black, brown, red, gray, purple, pink, white, orange and turquoise.

We know that a single-phase one is created by branching from a three-phase one. In this case, the phase conductor of a single-phase circuit must necessarily match the color of the phase conductor of a three-phase circuit with which it is connected.

In no case should the colors of the phase conductors coincide with the colors of the neutral and grounding conductors (N, PE, PEN).

Using stranded wire(cable) with single-color markings; colored marks are placed at the ends of the wires (after testing). For this purpose, color is used heat-shrink tubing(cambric) or colored electrical tape.

Conductor color in variable three-phase network

In three-phase networks, buses and high-voltage inputs of transformers at and substations must have next color: phase "A" - yellow, phase "B" - green, phase "C" - red.

Color of wires in DC network (+ and -)

As we know, a DC circuit uses only two wires. There is no phase or neutral conductor, but only positive (+) and negative (-) wires.

According to standards electrical conductors positive charge (+) conductors are colored red, and conductors of negative charge (-) are colored blue. The middle conductor (M) is indicated in blue.

Recommended articles:

Winding electrical wires

Anyone who has ever dealt with wires and electricity has noticed that conductors always have different color isolation. This was done for a reason. The colors of the wires in electrics are designed to make it easier to recognize the phase, neutral wire and ground. They all have a certain color and are easily distinguished during operation. The color of the phase, neutral, and ground wires will be discussed further.

How phase wires are painted

When working with wiring greatest danger represent phase wires. Touching the phase, under certain circumstances, can become lethal, which is probably why they were chosen for bright colors. In general, the colors of electrical wires allow you to quickly determine which of a bunch of wires are the most dangerous and work with them very carefully.

Most often, phase conductors are red or black, but other colors are also found: brown, lilac, orange, pink, purple, white, gray. Phases can be painted in all these colors. It will be easier to deal with them if you exclude the neutral wire and ground.

In the diagrams, phase wires are designated by the Latin (English) letter L. If there are several phases, a numerical designation is added to the letter: L1, L2, L3 for a three-phase 380 V network. In another version, the first phase is designated by the letter A, the second by B, and the third by C .

Ground wire color

By modern standards, the ground conductor is yellow-green in color. It usually looks like yellow insulation with one or two longitudinal bright green stripes. But there are also transverse yellow-green stripes in color.

In some cases, the cable may only have yellow or bright green conductors. In this case, the “earth” has exactly this color. It is displayed in the same colors on diagrams - most often bright green, but it can also be yellow. Signed on circuit diagrams or equipment “ground” in Latin (English) letters P.E.. The contacts to which the “ground” wire must be connected are also marked.

Sometimes professionals call the grounding wire “neutral protective”, but do not be confused. This is an earthen one, and it is protective because it reduces the risk of electric shock.

What color is the neutral wire?

Zero or neutral is blue or light blue, sometimes blue with a white stripe. Other colors are not used in electrical engineering to indicate zero. It will be like this in any cable: three-core, five-core or with big amount conductors.

“Zero” is usually drawn in blue on diagrams and signed with the Latin letter N. Experts call it a working zero, since, unlike grounding, it participates in the formation of the power supply circuit. When reading a diagram, it is often defined as "minus", while the phase is considered "plus".

How to check the correctness of marking and wiring

Wire colors in electrical engineering are designed to speed up the identification of conductors, but relying only on colors is dangerous - they could be connected incorrectly. Therefore, before starting work, you should make sure that you have correctly identified their affiliation.

Take a multimeter and/or indicator screwdriver. It’s easy to work with a screwdriver: when you touch a phase, the LED built into the housing lights up. So it will be easy to identify phase conductors. If the cable is two-wire, there are no problems - the second conductor is zero. But if the wire is three-wire, you will need a multimeter or tester - with their help we will determine which of the remaining two is phase and which is zero.

We set the switch on the device so that the selected jackal is more than 220 V. Then we take two probes and hold them plastic handles, carefully touch the metal rod of one probe to the one found phase wire, the second - to the assumed zero. The screen should display 220 V or the current voltage. In fact, it may be significantly lower - this is our reality.

If 220 V or a little more is displayed, this is zero, and the other wire is presumably “ground”. If the value is less, we continue checking. With one probe we again touch the phase, with the second - to the intended grounding. If the instrument readings are lower than in the first measurement, there is “ground” in front of you and it should be green. If the readings turn out to be higher, it means that somewhere there was a mistake with “zero” in front of you. In such a situation, there are two options: look for exactly where the wires were connected incorrectly (preferable) or simply move on, remembering or noting the existing position.

So, remember that when testing a phase-zero pair, the multimeter readings are always higher than when testing a phase-ground pair.

And, in conclusion, let me give you some advice: when laying wiring and connecting wires, always connect conductors of the same color, do not confuse them. This can lead to disastrous results - in best case scenario to equipment failure, but there may be injuries and fires.

In Russia there is no unified alphanumeric system for designating cables and wires. To do this, use the technical designation established by GOST for the materials from which the product elements are composed, as well as design features.

The brand of cable (wire) is the letter designation of the material of the current-carrying conductors, insulation, fire resistance, degree of flexibility and design of protective covers. After letter designation a digital designation is written down indicating the number of cores and their cross-section.

IN general case The cable brand is indicated according to Fig. 2.1.1.

The explanation of the abbreviations used for wires is as follows

- Hanging wires:

A - bare aluminum wire;

AC - aluminum-steel (the word “steel-aluminum” is more often used) bare wire;

SIP - self-supporting insulated wire;

ng - non-flammable.

Power, installation wires and connecting cords (GOST 26445-85), used for electrical wiring of buildings, have the following designations:

- The first letter indicates the core material:

space - copper wires;

L - tinned copper;

A - aluminum;

AM - aluminum-copper;

N - nichrome;

C - galvanized steel;

- second letter:

P - wire;

Ш - cord;

- the third letter stands for flexibility:

space - normal flexibility;

G - increased flexibility;

OG - high flexibility;

- the fourth letter indicates the insulation material:

R - rubber shell;

N - nairite rubber;

RN - rubber shell, flame retardant;

RM - frost-resistant rubber;

RT - heat-resistant rubber;

RI - insulating and protective rubber shell;

B - polyvinyl chloride;

P - polyethylene;

PL - film;

B - paper;

- the fifth letter indicates the design:

E - with screens along each core, with a common screen on top of the twisted cores, with a common screen on top of the sheath;

O - braided or wound from natural or synthetic threads;

B - in armor;

T - with a supporting cable;

- the sixth letter indicates the shape of the wire:

space - round;

P - flat;

C - spiral.

After the letters, the numbers 1, 2, 3, 4, 5, 6 can be inserted through a dash, indicating the class of the core according to GOST 22483-77. The higher the core class, the larger number wires are woven into it and, accordingly, the higher the flexibility of the core. Class 1 corresponds to a monowire core.

- Installation wires for wiring inside power cabinets are designated:

M - installation wire (placed at the beginning of the designation);

G - multi-wire conductor (the absence of a letter indicates that the conductor is single-wire);

Ш - polyamide silk insulation;

C - film insulation;

B - polyvinyl chloride insulation;

K - nylon insulation;

L - varnished;

C - fiberglass winding and braiding;

D - double braid;

O - polyamide silk braid;

E - shielded;

ME - enameled.

- Also, installation wires in accordance with GOST 17515-72 can be marked as follows:

NV - installation wire with a core made of tinned copper wires with insulation made of polyvinyl chloride plastic;

NVE - also shielded;

NVK - installation wire with a core made of tinned copper wires with insulation made of polyvinyl chloride plastic and a protective sheath made of nylon;

NVKE - also shielded;

NVM - installation wire with core copper wires with insulation made of polyvinyl chloride plastic;

NVME - also shielded;

NP - installation wire with a core made of tinned copper wires with polyethylene insulation;

NPE - also shielded;

NPK - installation wire with a core made of tinned copper wires with polyethylene insulation and a protective sheath of nylon;

NPKE - also shielded.

- In addition to the markings described above, there are the following:

PNSV - heating wire, steel core, vinyl sheath;

PVS - connecting wire in a vinyl sheath;

PUNP - universal flat wire;

PUGNP - universal flat flexible wire.

- Explanation of abbreviations used for designations power cables with PVC (vinyl) and rubber insulation (according to GOST 16442-80, TU 16.71-277-98, TU 16.K71 -335-2004):

A - (first letter) aluminum core, if absent - copper core by default;

AC - aluminum core and lead sheath;

AA - aluminum core and aluminum sheath;

B - armor of two steel strips with anti-corrosion protective coating;

Bn - the same, but with a non-flammable protective cover (does not support combustion);

b - without a pillow;

B - (first (in the absence of A) letter) PVC insulation;

B - (second (in the absence of A) letter) PVC sheath;

Г - at the beginning of the designation means that the cable is intended for mining, at the end of the designation - the absence of a protective cover over the armor or sheath (“bare”);

d - water blocking tapes for sealing the metal screen (at the end of the designation);

2g - aluminum-polymer tape over a sealed screen;

Shv - protective cover in the form of an extruded hose (shell) made of polyvinyl chloride;

Шп - protective cover in the form of an extruded hose (shell) made of polyethylene;

Shps - a protective cover made from an extruded hose made of self-extinguishing polyethylene;

K - armor made of round galvanized steel wires, on top of which a protective cover is applied; if it appears at the beginning of the designation - control cable;

C—lead sheath;

O - separate shells on top of each phase;

R - rubber insulation;

HP - rubber insulation and sheath made of flame retardant rubber;

P - insulation or shell made of thermoplastic polyethylene;

PS - insulation or shell made of self-extinguishing polyethylene (non-flammable);

PV - insulation made of vulcanized polyethylene;

BBG - armor made of profiled steel tape;

ng - non-flammable;

LS - Low Smoke - low smoke and gas emissions;

KG - flexible cable;

HF - do not emit corrosive gases

products during combustion and smoldering;

FR - fire resistant (withstands 750 °C for 180 minutes);

LTx - with low toxicity of combustion products.

- XLPE cables are marked as follows:

A - aluminum conductor (without designation - copper conductor);

VG - shell made of polyvinyl chloride plastic;

PV - insulation made of cross-linked polyethylene;

h - presence of water-blocking filling in the cable structure;

BB - armored;

Шп - polyethylene shell over armor;

Shv - a shell made of polyvinyl chloride plastic compound over the armor;

d — presence of water-blocking elements in the cable design.

- Cable with BPI - impregnated paper insulation (according to GOST 18410-73):

A - (first letter) aluminum core, if absent - copper core (by default), if in the middle of the designation after the core material symbol, then aluminum sheath;

B - armor made of flat steel strips (after the shell material symbol);

AB - aluminum armor;

SB - (first or second (after A) letter) lead armor;

C - lead shell material;

O - separately leaded conductor;

P - armor made of flat galvanized steel wires;

K - armor made of round galvanized steel wires;

B - paper insulation with depleted impregnation (placed at the end of the designation through a dash);

b - without a pillow;

l - the pillow contains an additional single lavsan ribbon;

2l - the pillow contains an additional double lavsan ribbon;

G - absence of protective cover (“naked”);

n - non-flammable outer cover (placed after the armor symbol);

Shv - outer cover in the form of an extruded hose (shell) made of polyvinyl chloride;

Шп - outer cover in the form of an extruded hose (shell) made of polyethylene;

Shvpg - outer cover made of extruded hose made of low-flammability polyvinyl chloride;

(ozh) - cables with single-wire conductors (placed at the end of the designation);

U - paper insulation with increased heating temperature (placed at the end of the designation);

C - paper insulation impregnated with a non-drip compound (placed in front of the designation).

- Control cable (according to GOST 1508-78):

A - (first letter) aluminum core, if absent - copper core by default.

B - (second (in the absence of A) letter) PVC insulation.

B - (third (in the absence of A) letter) PVC sheath.

P - polyethylene insulation.

PS - insulation made of self-extinguishing polyethylene.

G - absence of protective cover (“naked”).

R - rubber insulation.

K - (first or second (after A) letter) control cable.

KG - flexible cable.

F - fluoroplastic insulation.

E - at the beginning of the designation - a power cable for special mine conditions, in the middle or at the end of the designation - a shielded cable.

- Explanation of some special abbreviations:

KSPV - cables for transmission systems in a vinyl sheath.

KPSVV - cables fire alarm, vinyl insulated, vinyl sheathed.

KPSVEV - fire alarm cables, with vinyl insulation, with a screen, in a vinyl sheath.

In addition to cables made in accordance with Russian GOSTs, you can find cables from foreign manufacturers on sale. The most popular of them is the NYM cable, which is produced according to the German standard VDE 0250, part 204.

The NYM cable is close in purpose and parameters to the VVG cable and has improved performance characteristics: chalk-filled rubber filler between the cores and the sheath gives the cable round shape, which makes it easier to seal entry points into electrical devices and simplifies the cutting of ends (although the filler is flammable, in general the cable is self-extinguishing thanks to the PVC sheath, which does not propagate combustion). The domestic analogue of the NYM cable is the VVGz cable (“z” - with filler).

NYM is a German designation for cable, although this cable is mainly sold in Russia domestic production. Domestic analogues are often of poor quality and are often produced under the NUM brand.

- Marking of European cables (manufactured under European licenses):

har (harmonlzed) - products are standardized;

numbers 03, 05 or 07 - operating voltage, respectively 300/300, 300/500 or 450/750;

letters v or g - type of insulation, PVC or rubber, respectively;

letters U, R, K, F - type of conductor, respectively solid, stranded, flexible for fixed wiring, flexible.

When choosing cables, it is very important to consider the conditions for their installation:

— wires and cables with a flame-retardant vinyl sheath (PV, KG, PUNP, etc.) are allowed to be used only with a single hidden installation in structures made of non-combustible materials;

— PVC-insulated cables without the ng prefix (VVG, NYM, etc.) may only be laid openly one at a time;

— cables with the ng prefix for group installation in cable structures, outdoor (open) electrical installations (cable overpasses, galleries); use in cable rooms of industrial enterprises, residential and public buildings is not allowed;

— ng-LS — for group installation in cable structures and premises internal electrical installations, including residential and public buildings;

- ng-HF - for group installation in rooms equipped with computer and microprocessor equipment, for use in buildings and structures with large numbers of people;

- ng-FRLS and ng-FRHF - for single or group installation of power supply circuits for electrical receivers of fire protection systems, operating rooms and resuscitation and anesthesia equipment in hospitals and hospitals, as well as other electrical receivers that must remain operational in fire conditions;

- ng-LSLTx and ng-HFLTx - for single or group installation in preschool buildings educational institutions, specialized homes for the elderly and disabled, hospitals, dormitories of boarding educational institutions and children's institutions.

When laying armored cables in vinyl outer insulation (AVBbShV, APvBbShV, etc.) and with external insulation made of cord impregnated with bitumen (AABL, ASB, etc.), when laying indoors, it is necessary to remove the outer flammable sheath, and paint the exposed armor with Kuzbass varnish .

The number of cores and cross-section are indicated after letter marking as follows: number of cores x (multiplication sign) core cross-section.

The core cross-section for electrical cables is selected depending on the load from the following range: 0.75; 1; 1.5; 2.5; 4; 6; 10; 16; 25; 25; 35; 50; 70; 95; 120; 150; 185; 240 mm2. The choice of core cross-section is made depending on the type of cable and the installation method according to the PUE tables.

Cable marking is the use of sheaths of different colors, the application of inscriptions, the use of labels and tags, as well as electronic markers. The marker speaks about the properties of the cable and allows you to distinguish it from other similar products.

What are wire insignia?

The marking of power cables consists of letters indicating the material from which the sheaths, insulation, conductors are made, as well as the type of protection. High voltage cable designations include design features.

Copper conductors are not marked with a special letter in the inscription. Usually the aluminum core is the letter “A”, which is at the beginning of the marking. Then comes the letter that identifies the insulation material. Polyethylene insulation is designated by the letter “P”, polyvinyl chloride is designated by the letter “B”, and rubber insulation is designated by the letter “P”. Next comes a letter indicating the type of protective sheath, namely: the letter “A” is aluminum, the letter “C” is lead, the letter “P” is a polyethylene hose, the letter “B” is a polyvinyl chloride sheath, the rubber sheath is the letter “P” . The last letters indicate the type of cover.

For example, the "SG" brand has a copper core, paper insulation, a lead sheath, and no protective covers. The marking of an oil-filled cable contains the letter "M" (for gas-filled cables - the letter "G") and a letter indicating the oil pressure characteristics and related features. For example, the "MNS" cable is an oil-filled cable, low pressure, in a lead sheath, which has a protective cover.

And cables are carried out according to numbers and letters, according to GOST and TU: GOST 16442-80 and TU16.71-277-98.

Marking of power cables with rubber and PVC insulation

- “A” means core materials, aluminum. If there is no letter, then copper is the material.

- “AC” is an aluminum conductor with a cable sheath made of lead.

- “AA” is an aluminum core with a cable sheath made of aluminum.

- “B” - indicates that the cable has armor; it is made of two layers of tape with a special

- “Bn” - there is a special protective shell that does not support combustion.

- “B” is either first or second and means “polyvinyl chloride shell”.

- "G" - naked, without protective coating cable if “G” is at the end. If "G" is at the beginning, then it is used in the mining industry.

- “2g” - there is an additional aluminum-polymer tape.

- “Shv” - there is a protective sheath for the cable, which looks like a polyvinyl chloride hose (pressed out).

- “Shp” - the hose consists of polyethylene.

- "Shps" is self-extinguishing polyethylene.

- “K” - if the letter is at the beginning of the marking, then the cable is a control cable. If at the end, then the armor is made from which the cover is put on.

- "KG" - flexible cable.

- "C" - denotes the lead sheath of the cable.

- “O” - the sheath is made over all phases of the cable.

- “PV” - consists of vulcanized polyethylene.

- “P” - the cable insulation is made of rubber.

- “NR” - the cable insulation does not burn.

- “ng” usually comes at the end and means that the cable is not lit.

Inscription on the product BPI

BPI cable marking according to GOST 18410-73 (paper cable impregnated with insulation):

- “A” - aluminum core.

- “B” - the armor is represented by thin steel strips.

- "AB" - aluminum armor.

- "SB" - lead armor.

- “C” - lead - shell material.

- “O” - a separate lead vein.

- “P” - armor is made of galvanized steel flat wires.

- “K” - armor is made of galvanized steel round wires.

- “B” is paper insulation that has depleted impregnation.

- “b” - no pillow.

- “l” - there is a pillow, and it includes a Mylar ribbon.

- “2l” - double tape included.

- “G” - there is no protective cover.

- “n” - the outer cover is non-flammable. Placed after the reservation.

- “Shv” - the cover is represented by a pressed hose consisting of polyvinyl chloride.

- “Shp” - the cover is represented by a pressed hose consisting of polyethylene.

- "Shvpg" - polyvinyl chloride has reduced flammability.

- “ozh” - single-wire conductors. Placed at the end.

- "U" - paper insulation, which elevated temperature heating

- “C” is paper insulation that is impregnated with a non-draining compound.

Control cable

Control cable marking:

- “A” - aluminum or copper conductor, if there is no aluminum conductor.

- “B” - (second) PVC insulation.

- “B” - (third) PVC sheath.

- “P” - polyethylene insulation.

- "Ps" - self-extinguishing polyethylene insulation.

- “G” - there is no protective cover.

- "R" - rubber insulation.

- “K” - (second or first letter) control cable.

- "KG" - flexible cable.

- “F” - fluoroplastic insulation.

- "E" - if at the beginning, then this electrical cable, the marking of which says that it is suitable for standard conditions, and if at the end or in the middle, then it is a shielded cable that is used to protect against electromagnetic radiation.

Using letters in combination with numbers

There is also an alphanumeric cable marking. Explanation:

- AVVGng 3x4 - three-core cable, aluminum. With a cross section of 4 squares. The shell and insulation consists of polyvinyl chloride, there is no protective cover and does not support combustion.

- PVG 3x2.5 - three-core copper cable. With a cross section of 2.5 square. There is polyethylene insulation. The protective shell consists of polyvinyl chloride, there is no protective cover.

- ASB 7x2.5 - seven-core cable, aluminum. With a cross section - 2.5 square. The shell is made of lead and has armor.

That is, such marking shows the cross-section of the cores and their number.

Decoding a special abbreviation

Marking of wires and cables that have a specialized abbreviation:

- KSPV cables are designed for special sheathed transmission systems.

- KPSVV - cables are intended for fire alarms.

- KPSVEV - cables are designed for fire alarms, only they include a screen.

- PNSV - heating wire with a steel core.

- PV-1, PV-3 - vinyl insulated wire. Core flexibility - 1.3 class.

- PVA is a wire with a vinyl sheath (connecting).

- SHVVP - vinyl insulated cord (flat).

- PUNP - flat universal wire.

- PUGNP - flexible flat universal wire.

Distinguishing products from each other using different colors

For correct use cables, it is necessary to distinguish them from each other. To make this easier, the cable is color coded.

To identify cables use brown, black, red, yellow, orange, green, purple colors. And also blue, white, gray, turquoise and pink. This list is established according to GOST.

The blue wire is for the middle or neutral working conductor.

Various color combinations can be used. Green and yellow cannot be used in combinations other than the yellow-green combination, and it is used to indicate the protective neutral conductor.

If the neutral protective conductor is combined with the neutral working conductor, it is designated either along the entire length by a yellow-green combination, and at the ends with light blue, or light blue along the entire length, and at the ends with a combination of yellow and green.

Examples of core identification:

1. Color identification of cores that are insulated with polyvinyl chloride plastic:

Three-core cable: black, blue, brown or a combination of yellow and green, black, blue;

Four-core cable: combination of yellow and green (neutral protective conductor), black, blue, brown.

2. Color identification also exists for three single-core cables, painted black:

One cable with a blue mark;

One cable without a mark or with a black mark;

One cable marked brown.

3. Color identification according to the functional meaning of the circuits:

For conductors having power circuits, this is black;

For conductors having control circuits, signaling and measuring current that is alternating, it is red;

For conductors having control, signaling and DC current measurement circuits, it is blue;

For protective neutral conductors- combination of yellow and green;

For conductors that are connected to the neutral working conductor and are not intended for grounding - this is blue.

Tags used for inscriptions

Cable marking tags are used for marking control and power wires. They are made from polypropylene.

In case there are hidden wiring cables in walls or pipes, marking tags are fixed at the cable outlet and inlet, in wells and chambers of block sewerage and in the case of cable laying, marking tags are installed at each box or at the end. To install the cable in damp areas, tags are made of plastic.

Tags are:

Marking cable U-134;

Marking cable U-153;

Marking cable U-135;

Marking cable U-136.

So, as can be seen from the article, the marking of wires and cables (GOST, by the way, is what the consumer should first pay attention to when purchasing) is very diverse. AND to an ordinary person It won't be easy to deal with this. Therefore, we will give advice: to work with cables and wires, seek the help of specialists. It will be good if the services of this master include not only necessary work, but also purchase the required material, so that you don't get confused. If you decide to self-execution any work related to cables and wires, then we should wish you good luck in this difficult task!

When working with electricity, you may notice that the wire strands are colored different colors. Interestingly, the colors are never repeated regardless of the number of conductors in one shell. Why is this done and how not to get confused color variety– this is what our article is about today.

The essence of color coding of wires

Working with electricity is a serious matter as there is a risk of electric shock. It is not so easy for an ordinary person to cope with connecting wires, because when you cut the cable, you can see that all the wires have different colors. This approach is not an invention of manufacturers in order to distinguish their products from competitors, but is very important when installing electrical wiring. To avoid confusion with the color of cable cores, all the variety of colors has been reduced to one standard - PUE. Electrical installation rules state that wire cores must be differentiated by color or alphanumeric designation.

Color coding allows you to determine the purpose of each wire, which is extremely important when switching. Correct connection lived among themselves, as well as when installing electrical installation products, helps to avoid serious consequences, such as short circuit, electric shock or even fire. Properly connected wires help subsequently carry out repairs and maintenance without problems.

According to the rules, the color of the wires is present along the entire length. However, in reality you can find electrical wires painted in one color. Most often this occurs in old housing stock, where aluminum wiring. To solve problems with the color designation of each individual core, heat-shrinkable tubing or electrical tape of different colors is used: black, blue, yellow, brown, red, etc. Multi-colored markings are made at the connection points of the wires and at the ends of the wires.

Before talking about color differences, it is worth mentioning the designation of wires with letters and numbers. Phase conductor in single-phase network alternating current is designated by the Latin letter "L" (Line). IN three-phase circuit phases 1, 2 and 3 will be designated "L1", "L2", "L3" respectively. The grounding phase conductor is designated by the abbreviation “LE” in a single-phase network and “LE1”, “LE2”, “LE3” in a three-phase network. Neutral wire assigned the letter "N" (Neutral). The neutral or protective conductor is designated "PE" (Protect Earth).

Ground wire color code

According to the standards for the use of electrical equipment, all of it must be connected to a network that has a ground wire. It is in this situation that the manufacturer’s warranty will apply to the equipment. According to PUE protection consists of a yellow-green shell, and the color stripes must be strictly vertical. With a different arrangement, such products are considered non-standard. You can often find wires in a cable with a bright yellow or green sheath. In this case, they are used as grounding.

Interesting! Hard solid wire grounding is painted green with a thin yellow stripe, but in soft stranded, on the contrary, yellow is used as the main one, and green acts as an additional one.