Electrician is one of the most dangerous professions. In order to protect personnel as much as possible, the company provides them with special clothing and footwear with electric arc protection. In addition to this, (PPE) and professional power tool. Special attention is given to work under voltage and at height. For this purpose, workers are provided with additional equipment with protective properties. These include safety harnesses, stepladders, and mats. One of the interesting devices that can be classified as both personal protective equipment and tools is an insulating rod.

What does she do? This type of equipment allows you to work with electrical installations that are energized, but not more than 550 kV. Depending on the functionality, these tools are divided into two main types. There is an operational and measuring rod. We will consider their features further in our article.

Design features

The tool is a handle that can be divided into three segments. This is a handle, an insulating part, and also a working part. Such a tool for an electrician can be assembled or telescopic. The main thing is to provide the insulating element with strong link adhesion. For this purpose special metal fastenings, but their total length should not exceed five percent of the length of the insulating part.

The working tip is made of metal or some dielectric material and, depending on its purpose, may have different shape and functionality.

The insulating part is made of materials that do not conduct current. For example, it can be ebonite, bakelite, wood and others. According to the technology, they are thoroughly boiled in linseed or hemp oil and dried. After this, the material is coated with an insulating varnish on top to protect it from moisture penetration inside.

The handle is most often made of the same material as the insulating part. A restrictive ring must be installed between these areas, which will prevent contact between the hand and the insulating area during operation. The limiter must protrude at least ten millimeters and have a height of at least three millimeters.

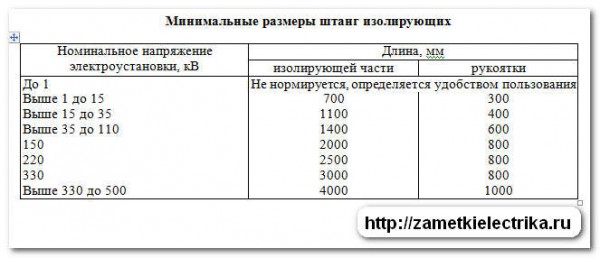

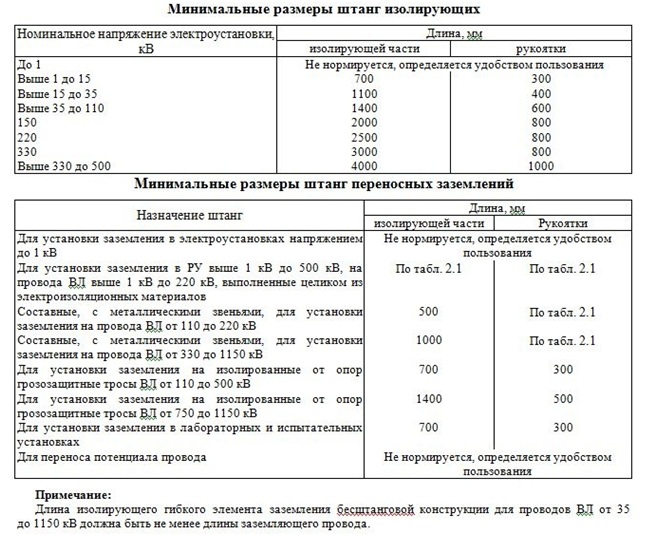

The total length of the rod according to state standard number 20494-2001 (“Rods isolating operational and elements portable grounding - technical specifications") depends on the voltage of the electrical installation on which the work is carried out.

In installations with voltages greater than 350 kV, tools are used for the work of two electricians, using a supporting device.

Basic parameters

The weight of the equipment for one person to operate should not exceed eight kilograms. The force per hand for measuring rods should not exceed 80N, for other types up to 160N. The length of the insulating part and the handle depends on the voltage, according to GOST 20494-2001.

Scope of elements

Work under voltage using a rod can be carried out in closed electrical installations, or outside, but in dry weather. Under no circumstances should you use this device in rainy, snowy weather or during fog and drizzle.  With such weather conditions there is a high risk of getting electric shock, which in some cases can lead to fatal consequences.

With such weather conditions there is a high risk of getting electric shock, which in some cases can lead to fatal consequences.

Using this tool, they perform operations with disconnectors, change fuses, install arrester parts, check insulation on power lines and substations, apply portable groundings, use them as a means of freeing an injured person from electric current, and carry out measuring work.

The modifications and capabilities of each type should be considered in more detail.

Operating rod

There are four types based on their main functionality:

- SHO (operative isolation). Used for large quantity work due to the replaceable head. Used on electrical installations with voltage up to 220 kV with direct or alternating current.

- SCO (rescue). With its help, you can rescue a person from the zone affected by electric current with voltages of up to 110 kV. Urgent release measures increase the chances of resuscitating the victim.

- SHOW (universal insulating rod). Used on electrical installations similar to SHO. At the same time, the maximum number of replaceable working parts increases functionality.

- ShZP (grounding connections). Also used in electrical installations with voltages up to 220 kV with direct or alternating current. This device allows you to approach areas with residual voltage or partial shutdown of the installation. By working with ShZP, the number of electrical injuries is significantly reduced.

The operating rod allows you to perform necessary work under voltage. This eliminates the risk of getting hit electric shock. The main thing is to follow the rules of operation, inspection and testing of PPE.

"Ticks"

A separate item worth highlighting is insulating pliers. The element allows you to replace fuses in electrical installations up to 1 kV and higher. They are also used for removing heads and fences in installations up to 350 kV inclusive.  It is allowed to replace this type of equipment with a universal operational rod with a corresponding working head.

It is allowed to replace this type of equipment with a universal operational rod with a corresponding working head.

Size and weight of this equipment should provide comfortable work for one person. The insulating part and the handle must be made of materials with dielectric and antistatic properties.

The clamps themselves can be made of electrically insulating materials or metal. Oil and petrol resistant tubes must be placed on the metal jaws so as not to damage the surface of the cartridges during operation.

The length of the insulating clamps also depends on the voltage:

- At voltages from 1-10 kV, the length of the insulating section is 450 mm, the length of the handle is 150 mm.

- At voltages from 10-35 kV, the length of the insulating section is 750 mm, the handle is 200 mm.

Measuring

Using this professional power tool, it became possible to identify surges in areas of an electrical installation that are in normal operating mode. There are two methods: by measuring the temperature of the contacts or by directly measuring voltage surges.

The measuring head is a spark gap adjusted in laboratory conditions. Displayed minimally valid value. Working head through parallel connection to the area being tested, using indicators, shows the presence or absence of voltage. It is important that the electrical installation is in normal operating mode at the time of inspection.

There are three main types:

- SHIU. This device provides the ability to change the distance between the electrodes, which allows you to most accurately obtain measurement data.

- SHI. Such devices are equipped with a dial microammeter with an additional resistance of up to 160 megaohms. Depending on the measurement method, a set of probes with conductors that are connected to the clamps changes at the working area. The probes are placed on the controlled insulator, and a parallel connection occurs. The microammeter needle shows the measurement result.

The SHI device is also used for the second method. Probes are installed to measure temperature on the contacts.

- It is a current transformer with a detachable magnetic core. For the primary winding, a conductor with the measured current is used, and the secondary winding is connected to either a switch or a digital one.

Operating conditions

The insulating rod must be used in external environment With temperature conditions from minus 45°С to plus 40°С at relative humidity 98% at 25°C.

The use of devices is not allowed:

- They do not have the appropriate certificates and have not passed the test, and therefore do not meet safety standards.

- Faulty. Such devices must be repaired. After which tests were carried out. And only based on the data received, a decision is made on further use or disposal of the device.

- At high humidity. In wet weather.

- Using supports (stepladders) during measuring work.

Workers with appropriate permits are allowed to work on electrical installations. Every employee must be equipped complete set PPE, including dielectric gloves, dielectric boots, workwear with electric arc protection, safety glasses and a respirator. All this will help to protect the worker as much as possible from electrical injuries.

Before work, the insulating rod must be subjected to visual inspection.  If a malfunction is detected, it must be replaced with another copy.

If a malfunction is detected, it must be replaced with another copy.

During operation, mechanical tests are not carried out. Scheduled and unscheduled repairs can be carried out if the device falls or defects are detected. The device is first repaired.

Carrying out tests

Since work on an electrical installation is classified as dangerous, electrician tools are subject to careful inspection and control. Moreover, depending on the equipment, tests are carried out at the manufacturing plant. According to GOST 20494-2001 they can be:

- Acceptance. Carry out for each product.

- Periodic. Each rod must be tested.

- Typical. Three samples of the same type are tested selectively. All types of testing will need to be carried out.

All testing activities are carried out by the manufacturer with the help of specially trained people who have a certain level of clearance and have undergone training and certification.  These operations must be carried out in a timely manner; the life and health safety of the electrician depends on it.

These operations must be carried out in a timely manner; the life and health safety of the electrician depends on it.

List of tests:

- Visual control. Checking completeness, labeling, packaging. The availability of the required documentation and compliance with the required safety regulations is checked.

- Checking compliance with factory drawings. Produced using there must be a complete match of parameters.

- Examination electrical insulation for strength. Produced by voltage AC industrial frequency with a single application for no more than five minutes. In this case, increasing the voltage to 1/3 of the value can be arbitrary. Further increase should be smooth. The working and insulating parts of the rod are checked. If it is not possible to conduct a test with a full measuring section, then this part of the rod is checked in sections. If no breakdowns, local heating from dielectric losses, or surface discharges are detected, then the product is considered to have successfully passed the test.

- Tensile test. One end of the rod is secured, the other is subjected to a load or winch. permissible load. The test passed successfully with no visible damage.

- Bending test. The product is fixed horizontally at two points at the restrictive ring and the end of the handles. The rod sample passed the test if there were no visible damages.

- Checking the greatest force on the hand. The horizontally fixed rod is secured using two points - the front (50 mm from the limit ring) and the rear (50 mm from the end of the handle) supports. The measurement is taken at the front support and the indicator should not exceed 160N. An insulating rod up to 1000V is not subjected to this type of test.

If the result is negative, the procedure should be repeated with a larger number of samples. If the data is repeated, the entire type of product is confiscated and the release of a new batch is prohibited until the reasons for the negative indicators are clarified and eliminated. In such situations, the test stamp is crossed out with a red line.

All tests are carried out in accordance with current standards.  For operational instruments, tests are carried out once every two years, for measuring instruments - once a year.

For operational instruments, tests are carried out once every two years, for measuring instruments - once a year.

Equipment selection

In order for an employee to be provided with correctly selected PPE and tools, the relevant state standards and regulations should be studied. This will help you choose the right kit for each type of work.

The price set for insulating rods will play an important role for the consumer when choosing a device. On average it is 500 rubles. But you shouldn’t chase cheap devices. You should carefully study the manufacturer and the package of documents provided by them. All products must pass pre-sale tests and have the appropriate stamp.

Bottom line

In conclusion, I would like to note that modern world cannot imagine himself without electricity. This means that it is impossible to do without measuring rods.  It's hard to imagine what would happen if the world's power went out. There will probably be chaos and panic. Therefore, people servicing electrical installations should be treated with great respect and respect, and the relevant authorities should provide them with all the necessary necessary means personal protection.

It's hard to imagine what would happen if the world's power went out. There will probably be chaos and panic. Therefore, people servicing electrical installations should be treated with great respect and respect, and the relevant authorities should provide them with all the necessary necessary means personal protection.

So, we found out what such a technical tool as an insulating rod is.

Page 6 of 16

Insulating rods are divided into operational and measuring according to their purpose. Operating rods are divided into simply operational, universal and with removable heads (working parts).

Operating rods, including universal ones and with removable heads, are intended for turning on and off single-pole disconnectors, for determining the presence of voltage (by a spark or using the working part of the voltage indicator screwed onto the rod), for replacing fuses above 1000V, for setting the spark gap, removing and installation of tubular arresters, for cleaning equipment insulation from live dust and for other work.

Measuring rods are intended for measuring the potential distribution along a garland of pendant insulators or along a column of pin insulators, quality control contact connections live parts by measuring voltage drop or contact temperature, etc.

An insulating rod, regardless of its purpose, has three main parts: a working part, an insulating rod and a handle. The design of the working part is determined by its purpose. The working part of the measuring rod is the measuring device. The insulating part of the rod is the section from the outermost part (towards the insulating part) metal element working part to the handle. The insulating part of the rod is made of durable, lightweight and non-hygroscopic or treated moisture-resistant coatings insulating material. Typically, bakelite or glass epoxy tubes, as well as DSPBE laminated plastic, are used for rods. rectangular section.

The handle can be integral with the barbell or be a separate link. The handle is usually made of the same material as the insulating part. The insulating part of the rod on the handle side is limited by a ring or stop made of insulating material. The diameter of the restrictive ring should be 5-20 mm larger diameter handles. The stop does not allow the operator to touch the rod by its insulating part and thereby reduce its length, i.e. approach its working part. Therefore, it is prohibited to mark the boundary between the insulating part and the handle only with a belt of paint.

The dimensions of the insulating rods are determined by the voltage of the electrical installation for which the rod is intended, and should not be less than the values specified in the table. 8.

Table 8

Minimum dimensions insulating rods (according to GOST 20494-75)

In rods for voltages up to 15 kV with porcelain insulators and extensions made of insulating material, the minimum length of the insulating part includes the length of the insulator and the part of the extension from the insulator to the handle. The dimensions of the working part of the rod are not standardized, but they should not lead to a phase-to-phase short circuit or a short circuit to grounded parts.

The total length of the insulating rods is determined by the working conditions and should allow them to be freely used from the floor, from the ground, and on overhead lines - from supports.

For greater convenience during transportation, the rods can be made of several links (with a link length from 0.8 to 2.0 m), to connect which it is allowed to use metal parts. Connecting metal parts, the total length of which should not exceed 5% total length insulating part are not excluded when determining the length of the latter according to table. 8. The rigidity of the rod is regulated by the deflection tolerance, which, when horizontal position of the rod and the double weight of the working part (for universal operating rods with a removable head, as well as measuring ones) or under the influence of the rod’s own weight (for operational rods) should not exceed 10% of the length of the insulating rod. The weight of the rod, if one person works with it, must be such that the maximum force on one hand (supporting the rod at the restrictive ring) does not exceed 78 N (8 kgf) for the measuring rods, and 157 N (16 kgf) for the remaining rods. . With greater force, the participation of a second person and the use of a support device are necessary.

Operating rods have a working part in the form of a tip with a finger with a thickening at the end to prevent slipping during operations with disconnectors (Fig. 19), or in the form of a special head with a grip (for operations with tubular arresters).

The Troitsk Electromechanical Plant produces operating rods of types ШО-10, ШО-35, which are designed to control single-pole disconnectors and be used in conjunction with a voltage indicator to check the presence or absence of voltage on live parts. The working part of these rods, made of AL-2 aluminum alloy, has a pin for operations with disconnectors and a threaded bushing for attaching a voltage indicator of the UVN-10 type. The insulating part and the handle are made of wood-laminated plastic DSPBE. For rods of the SHO-YUTCH, SHO-35TCH brands, made in tropical design, the insulating part and the handle are made of STEF fiberglass, and the finger is made of stainless steel. The ShR-110 type rod produced by the same plant is designed to regulate the spark gap and remove tubular arresters in switchgear and on 110 kV overhead lines. The working part of the rod

is a head with grips that clamp the discharge pipe. The design of the working part allows operations with fuses at any angle of inclination of the head. The compression of the head grips is carried out under the action of a threaded cone. The dimensions of the operating rods manufactured by the Troitsk Electromechanical Plant are given in Table. 9.

Operative universal rods have special heads that allow you to perform several operations, i.e. they combine the functions of rod types

Table 9

Dimensions of operating rods type ШО иШР

Length, mm |

|||

Rod type |

insulating part |

handles |

Weight, kg |

Notes: I. Permissible force when working in tension and compression is 294 N (30 kgf).

2. Barbells operational type ShO are manufactured according to TU 16-638.231-74, and "tropical version (type SHOT according to TU 16-538.230-74.

ШО and ШР and insulating pliers for operations with fuses. Operational universal rods of the SHOU type are designed to control disconnectors, use in conjunction with a voltage indicator to check the presence or absence of voltage on live parts, to replace tubular fuses, remove surges and other work. The working part of these rods is a head with sliding grips (Fig. 20).

Rice. 20. Working and insulating parts of the universal operating rod of the SHOU type.

A finger is welded to one of the jaws for operations with disconnectors. The dimensions of SHOU type rods are given in table. 10.

Measuring rods are intended for monitoring suspension and post-pin insulators of lines

Table 10

Dimensions of operational universal rods type SHOW

Rod type |

Length, mm |

Weight, kg |

|

insulating part |

handles |

||

Note. The dimensions of rods manufactured by the Moscow Mechanical Plant (TU 34-1635-75) are indicated without brackets, and those manufactured by the RETO Mosenergo plant (TU 34-3817-74) are indicated in brackets.

power transmission and electrical substations 35-500 kV, monitoring the condition of wire and bus contacts, as well as for measuring the temperature of live parts.

Rods for monitoring insulators.

Based on the design of the working part, the rods for monitoring insulators are divided into two main subgroups - control and measuring. The first subgroup (control rods) includes devices with which you can only estimate the voltage on the insulator, establishing whether its voltage exceeds or does not exceed a predetermined value.

Measuring rods can directly measure the voltage drop across an insulator or an individual insulating element when the entire insulating structure is under the operating voltage of the electrical installation.

The main element of the measuring head of the control rod is the spark gap, which is adjusted in the laboratory before measuring the discharge at a certain voltage, usually the lowest permissible for the insulators that are to be controlled. Using an insulating rod and special probes, the spark gap is connected in parallel to the controlled insulator (element) under operating voltage, and the presence or absence of the required voltage on the insulator is determined by the spark effect. Typically, such rods are manufactured by operating organizations. They are simple in design and have a relatively small mass.

The disadvantages of test rods include the inability to measure the voltage drop across the insulator and the large error in determining the test results.

More advanced are measuring rods, the heads of which are recent years significantly simplified, lightweight and differ little in weight from the control rods.

The main advantage of measuring rods over control rods is the ability to measure the voltage drop on each insulator of a garland or each element of an insulating support structure that is under operating voltage.

Rice. 21. Universal measuring rod with a head for monitoring insulators.

1 - handle; 2-5 - insulating links; b - scale; 7 - suspended block with nylon halyard; 8 - grounding conductor with a clamp (only for 500 kV overhead lines); 9 - rocker arm; 10 - probes; 11 - fixed electrode; 12-movable electrode.

Universal measuring rods type ШИУ

Universal measuring rods of the ShIU type designed by SKTB VKT with a variable spark gap. Measuring rods of the ShIU type differ from others by the presence of a device for changing the distance between the electrodes of the spark gap, with the help of which the voltage drop across the controlled insulator is measured.

The spark gap of the measuring head of such a rod is pre-calibrated and equipped with a scale in kilovolts. Therefore, by changing the distance between the electrodes until the spark gap breaks down, it is possible to determine for each controlled insulator the value of the voltage present on it.

Changing the distance between the electrodes of the measuring head of the rod is carried out by rotating the insulating part of the rod and the movable electrode associated with it relative to the longitudinal axis.

Using SHIU type rods you can control without removing the voltage: suspended insulators on 35-500 kV overhead lines; post-pin insulators in RU 35-220 kV, rod-support and suspension insulators, condition of connecting clamps of wires and buses.

These rods can also be used to remove casts, measure dimensions, etc.

Included universal rod includes the insulating part (the rod itself), sets of measuring heads and auxiliary devices. General view The SHIU rod assembly with the head is shown in Fig. 21.

There are two groups of rods: ШИУ-220 - for work on overhead lines and in switchgear 35-220 kV (TU 34.28-3824-76), ШИУ-500 - for work on overhead lines 330-500 kV (TU 34.28-3833-76).

The SHIU-220 rod includes an insulating part made of four lightweight bakelite links 1 m long and a 1 m long handle with a thrust ring. If necessary, the rod can be extended with extensions made of wood or other material, attached to the handle, where a threaded sleeve is provided for this purpose. Such extensions can be manufactured locally. The set of measuring instruments of this rod includes a head for measuring the voltage drop on insulators of overhead lines and switchgear 110-220 kV, a head with a capacitor for measuring the voltage drop on insulators of overhead lines and switchgear up to 35 kV, a head for monitoring connecting terminals with a millivoltmeter for 5-25- 125 mV.

The head for measuring the voltage drop on insulators of VL and RU 35 kV differs from a similar head for 110-220 kV by the presence of a separating capacitance that prevents a phase from being shorted to ground when the spark gap of the measuring head is bypassed by an undamaged element in a two-element design when the second element is damaged. A capacitor with a capacity of about 25 pF is built into the rocker arm of the head and is designed for a test voltage of 35 kV. The scale in this head is calibrated up to 20 kV.

The head for monitoring contacts consists of a rocker arm on which special probes are located, connected by conductors to a 5-25-125 mV millivoltmeter mounted on the rod itself. Contact monitoring is carried out by measuring the voltage drop across the contact being tested and comparing the result obtained with the voltage drop over a section of equal length of the whole wire at the same current load.

The SHIU-220 rod must have at least two insulating links and a handle for voltages of 35, 110 and 154 kV, and at least three insulating links and a handle for 220 kV.

If necessary (due to dimensions or for the convenience of measurements), the rod can be assembled from more links than indicated above. When using four or more insulating links (not counting the handle), the rod should be supported during measurements with the insulating nylon rope included in the kit. To measure voltage, the head is placed on the insulator so that the stationary electrode is on the side of the current-carrying part, after which the rod is rotated clockwise relative to the longitudinal axis. The voltage is recorded on a scale at the moment of breakdown of the spark gap. The weight of the rod with the head is about 4 kg.

The ShiU-500 boom differs from the ShiU-220 boom in the following:

1. The insulating part is equipped with another 1 m long link (a total of five insulating links except the handle). This insulating link has a thrust ring in the middle and is used when monitoring the insulators of tension garlands, and also, if necessary, as a rod extension.

2. The handle is equipped protective grounding, used in the control of insulators of supporting garlands (in release rods before 1976).

The voltage measurement limits on the head scale have been expanded to 30 kV (instead of 25 kV).

To control double and triple tension garlands, a special sliding head (slider), manufactured to special order, is used.

The ShiU-500 boom must have:

for voltage 330 kV - at least three insulating links and a handle;

for voltages of 400 and 500 kV - at least four insulating links and a handle.

Manipulation of a rod with four or more insulating links is carried out by two operators with the obligatory use of an insulating rope.

When measuring the voltage drop on the insulators of tension garlands of VL 330-500 kV, the insulating part of the rod is equipped with another special insulating link, installed second from the head, with a restrictive ring in the middle, which determines the smallest permissible length insulating part when the head is located directly at the traverse. Instead of a regular head, a sliding slider head is used. The slider head (Fig. 22) is a lightweight frame made of insulating material (for example, fiberglass) with a measuring head and probes attached to it.

The design of the frame allows you to install and move the slider along the insulators of two adjacent garlands of the same phase.

The voltage on the insulators is measured, as usual, by turning the insulating part of the rod clockwise.

As the slider moves along the insulators and moves away from the traverse, the insulating part is extended with new links or moves in the hands if it has been completely pre-assembled. When the slider reaches the last insulators from the traverse, the insulating part of the rod (except for the handle) must consist of at least four links for 400 and 500 kV overhead lines (three for 330 kV overhead lines).

To measure the voltage drop on the insulators of the lower garland with a triangular arrangement of garlands of one phase, probes are installed longer. SHIU rods are stored and transported in cases, and measuring heads - in special suitcases.

Measuring rods type SHI.

The Troitsk Electromechanical Plant has developed and produced universal measuring rods of the types SHI-35, SHI-110 and SHI-220 (TU 16-538.232-74), which use a pointer microammeter with an additional resistance of 150-160 MOhm as a measuring device.

In addition to monitoring suspension and support insulators, rods can be used to check contacts of overhead lines and outdoor switchgear and remove surges (Fig. 23). The working part of the rod is a removable head with two pairs of replaceable probes and a measuring device PSh-61 or

PSH-67. Inside the bakelite tube of the measuring head's rocker arm there is an additional resistance that is switched on when measuring the voltage on the insulators in series with the device - a microammeter. The rocker arm has a swivel connection with the device holder, allowing measurements to be taken when the head is tilted relative to the rod axis up to 45°.

Rice. 23. Measuring rod type SHI.

a - rod assembled with a head for monitoring insulators; b - head for monitoring contacts; c - head for removing burrs; I - insulating part of the rod; 2 - meter; 3-rod head for monitoring insulators; 4 - contact probes.

Depending on the object of measurement (insulator or contact), special conductors from the probes are connected to one or another clamp located on the back of the device. When applying the head probes to the controlled insulator, the microammeter is connected to it in parallel through an additional resistance. The measurement result is read by the indication of the arrow on the instrument scale, which has five large divisions of 5 kV.

To monitor contacts, the conductor from one of the probes is connected to the corresponding (depending on the measurement limit) clamp on the device, the other probe is connected to the common terminal of the device. The rod makes two measurements of controlled contact. During the first and second measurements, notched grips are symmetrically applied to the contact connection being tested. Then a third measurement is made, for which the grips are placed on the entire wire or bus. The condition of the connecting terminal is assessed by comparing the voltage drop across the terminal under test with the voltage drop over a section of the same length of a whole wire at the same current load.

The removable head for deburring is a conical three-pin plug with dimensions 70X230 mm. The insulating part of the rod can consist of three varnished bakelite tubes connected by steel couplings and selected in such a way that during storage and transportation the tubes fit into one another like telescopic systems.

Another type of insulating part of the SHI rod is links made of laminated plastic DSPBE of rectangular cross-section, connected using metal couplings with screws. The dimensions of the SHI rods are given in table. 11.

Rods for measuring the temperature of live parts.

Measuring rods with an electric thermometer are intended for measuring the temperature of contact connections of live parts under voltage.

Table 11

Dimensions of measuring rods type Shi of the Troitsk Electromechanical Plant

Note. Values in parentheses are for rods made of wood plastic.

Known are rods with electric thermometers of types ET-1 and ET-2, developed by SKTB VKT Mosenergo.

The rod with the ET-1 electric thermometer is designed for use in electrical installations up to 10 kV inclusive. A sensor with a thermal resistance is mounted at the end of the rod, and a measuring device calibrated in degrees Celsius is installed on the insulating part.

The measuring head with an EG-2 type electric thermometer is designed to be mounted on a rod designed for use in electrical installations with voltages of 35 kV and above.

The sensor of these electric thermometers is equipped with a contact that closes only when the sensor is pressed on the surface whose temperature needs to be measured. The contact includes a battery circuit that powers a bridge circuit to measure resistance, the value of which is proportional to the temperature of the contact. The resistances of the bridge arms are mounted in the device body. Microammeters with a measurement limit of 0-100 μA are used as meters in electric thermometers.

Order:

Testing of operationally insulating dielectric rods

Tel. manager: 495 195 03 88

Email for order: zakaz@site

Operative insulating rods are designed to solve operational problems during installation and repair of electrical installations. They are used for testing line connectors, measuring insulation, installing arresters and other parts in substations, power lines and various electrical installations. The rods consist of three elements - a handle, an insulating part and a working part.

To make the insulating part of portable grounding rods, special electrical insulating materials that are resistant to electric current are used. To check quality characteristics instrument laboratory of high-voltage electrical measurements LLC "EnergoServiceGarant"» conducts operational tests of insulating rods with the provision of protocols drawn up in accordance with all rules.

Frequency of testing insulating rods

Operating portable grounding rods can be composite and contain several metal current-carrying links. It is allowed to use rods when working in electrical installations with voltages over 110 kV. The rods must have a design that provides a reliable detachable or permanent connection of portable grounding and current-carrying links with its subsequent fastening.

After receiving insulating rods from the warehouse or from the manufacturer, testing must be carried out before their use, as well as during operation. increased voltage. The testing periods for insulating rods are established by regulatory documents and require their inspection 1-2 times a year.

Testing of insulating rods

We test operational insulating rods designed for operation on electrical installations with voltages from 1 kV to 110 kV line voltage not less than 40 kV, and rods intended for operation on electrical installations with voltages of more than 110 kV - with a voltage equal to three times the phase operating voltage, but not less than 40 kV. During the tests, the test voltage is applied to a temporary electrode installed at the restrictive ring of the insulated part and to the working part of the tool. Testing time for operating rods is 5 minutes.

Stationary laboratory "EnergoServiceGarant"» carries out testing of operational insulating rods for operation on electrical installations up to 1000 V and more. Tests are carried out in as soon as possible, based on the test results you receive a signed responsible persons verification protocol.

We carry out high-quality testing of personal protective equipment and tools for working with high-voltage equipment. The check meets all the requirements of regulatory documents, current standards and rules. Before testing, the dielectric rod is carefully inspected. If there are defects, they are considered unusable and removed from testing. If external inspection gives positive result, the electrical and mechanical characteristics of the products presented to us are checked. We carry out testing in a laboratory equipped with the latest technology.

Good afternoon, dear guests Electrician's Notes website.

We continue to study the issues. And today our article is devoted to something called an insulating rod.

The use of insulating rods is very diverse. I won’t list everything. I will only say the most common.

Insulating rods are used for:

work of duty personnel - (removal and installation of fuses, actions with disconnectors, switches, etc.)

Depending on their application, insulating rods are divided into:

operational

for portable grounding

measuring

All requirements for insulating rods for various purposes are given in GOST.

Structurally, the insulating rod consists of 3 parts:

working part

insulating part

lever

Insulating rods can be either solid or composite. The latter usually consist of several links, which are interconnected by parts made of insulating materials or metal.

There are insulating rods with a telescopic design. A special requirement is placed on them for fixing the links of the connections.

Operating rods have a replaceable working part, namely replaceable heads, to perform various kinds operations and actions.

The weight of insulating rods for voltages up to 330 (kV) should be such that one person can work with them. Already above 500 (kW), the weight of the rod can be greater, and accordingly, these rods must be operated by 2 people using supporting devices.

Below I will provide two tables with the main dimensions of insulating rods for different purposes.

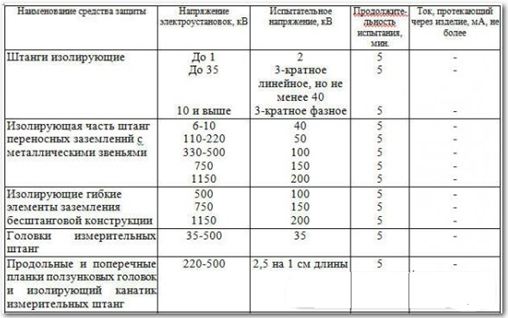

Testing of insulating rods

Insulating rods are carried out only. The scope of testing includes high voltage testing of the insulating parts of the measuring and operating rods.

The test voltage is applied between the working part and a temporary electrode (ring), which is pre-installed at the boundary of the working and insulating parts.

Because There is a wide variety of insulating rods, as well as the voltage class where they are used, then you can use the following table to carry out tests. The table shows all types of insulating rods different classes voltage, duration and frequency of their tests.

Insulating rods for installing (removing) portable grounding connections with metal links for air lines experience similarly. The remaining rods for portable grounding are not subject to electrical testing.

Rules for using insulating rods

Before carrying out work using an insulating rod, you must ensure its integrity and the presence of a test stamp.

Integrity is determined by visual inspection. The rod must not have mechanical damage.

It is also necessary to check the joints of the composite rod.

When working with measuring rod it does not need to be grounded.

When performing work from a height, you must climb to the height mark and descend without an insulating rod.

And one more important point. It is only necessary to use an insulating rod in electrical installations above 1000 (V).

P.S. This concludes the article on the topic of insulating rod. Remember and follow all measures.

Electric shock can cause disability and even death. Therefore, to protect workers during work, many protective devices and tools are used. One of them is considered to be an insulating rod - these are special rods that are made of non-conducting materials. They can touch electrical installations that are energized. They also serve as a rescue element (freeing the victim from the effects of electricity).

Types of insulating rods

Depending on the purpose, this protective agent is divided into the following types:

- Operational rod. It is used to connect/disconnect single-pole disconnectors, to check the presence or absence of current, to clean the insulation of live equipment from dust, to remove/install tubular arresters and other similar work.

- Universal. Purpose of this device diverse. Basically, it can be used to perform the same operations as with an operational device.

- Measuring. Used for measurements in electrical installations that are in operation.

- Repair. Used for installation and repair work near parts or installations that are under load. It is also used to clean insulators from dust and check for voltage in the cable.

The photo below shows several types of insulating rods:

This protective agent consists of the following parts:

- working part (this is the main part that determines the purpose of the device);

- insulating (ensures human safety from electric shock);

- handle (needed to hold the device, as a rule, this is an extension of the separating part, which is separated by a ring).

Also, devices are divided into solid and composite. The latter are a structure of several links that are connected using a special separating part.

They can also be operational. This design is a device with a replaceable working part. Thanks to this, the working head can change depending on the type of work and action.

As for weight, such an insulating protective equipment should not be heavy for a person. After all, he will have to work with him for some time. But there are structures that have significant weight. Then two workers work with it using supporting structures.

Size tables depending on purpose:

Test technology

There is one test method for this protective equipment - the separating elements of operational or measuring devices are tested with increased voltage.

There are a lot of varieties of insulating rods, and accordingly there are also many voltage classes where they are used. Therefore, when carrying out checks, they use a special table where all the names of structures are indicated depending on the voltage class. The frequency is also indicated there. test work and their duration.

This is what the table looks like:

The test method for testing an insulating rod with increased voltage is demonstrated in the video:

Terms of use

Before starting work, the protective agent used should be checked to ensure its suitability. To do this, check the integrity of the structure and the presence of the test stamp. The insulating rod must not contain mechanical damage; the absence of defects at the connection points is mandatory. The stamp must contain the voltage value (in kV) up to which use is permitted and the date of the next test. For example:

If work is performed at height, then you should climb to a certain height and descend from it with your hands free.

Important! Protective agent that is used in electrical installations over 1000 V is used only using