have recently become one of the most common pieces of furniture. This design provides convenient. Most often, they are not purchased ready-made, but made to order. But if you have the opportunity and the necessary materials, you can make a furniture set yourself. Before you begin, you need to decide on the number/location of shelves and drawers. It is also important to plan the design taking into account the dimensions of the room. In any case, all these points need to be studied before making a wardrobe with your own hands. In this case, the drawings are a kind of starting point, and our review today will help you cope with this rather difficult task with a minimum of errors.

A feature of this type of furniture designs is that they allow you to save usable space in the room. At the same time, sliding doors for a wardrobe can be glass, mirror, rattan, plastic or bamboo.

So, let's look at the main advantages of furniture sets:

- variety of designs: built-in, rectilinear, cabinet and;

- furniture sets allow you to effectively use even a small space. This is an ideal solution for small spaces. At the same time, mirror surfaces allow you to visually increase the space;

- brevity of designs;

- filling wardrobes. Such furniture sets allow you to hide everything unnecessary. They are used not only for clothing, but also for various household items and small appliances;

- models can be built-in, cabinet and with mezzanines;

- the wall of the room, as well as the floor or ceiling can be used as the walls of the cabinet;

- wardrobes are made to order;

- possibility of independent design.

It is worth noting some disadvantages:

- rapid wear of the sliding system;

- high-quality internal filling of the cabinet is required;

- the aluminum profile may be deformed;

- Careful maintenance is required: cleaning all surfaces and guides.

For your information! To prevent the door from coming off the rail, Schlegel for sliding wardrobes is used at the joints and ends. It needs to be glued, which will create shock absorption when the doors are opened suddenly.

Types of wardrobes

Let's look at the main types of wardrobes:

- built-in models that do not have a floor, back wall and ceiling. Such headsets cannot be moved or rearranged. They consist of side walls, shelves and internal partitions. Built-in models are made to order, but you can also purchase separate elements for self-assembly;

- free-standing sliding wardrobes are equipped with doors that move on a rail. This design has a floor, a back wall and a ceiling;

- corner headsets are suitable for small spaces. It is compact in size but very spacious inside. Corner design is suitable for a small rectangular room or square hallway;

- diagonal corner completely occupy the entire corner. Such designs are more spacious and look stylish. Inside you can hide not only a wardrobe, but also bed linen and blankets.

Wardrobe materials

Before you start making a corner cabinet or any other with your own hands, decide on the material.

Tree

For durable sets, you should choose solid wood. This is a prestigious material for furniture. It is worth considering that wood is not the best option for a built-in wardrobe. The humidity level is higher in the niche. For a wooden cabinet, you must carefully select wood that is free from cracks and knots. The frames of the doors are also made of wood. In this case, it is necessary to glue them together.

Wooden sets have the following advantages:

- environmental friendliness of the material. The tree does not contain toxic components;

- increased level of wear resistance;

- aesthetics of products. Wood furniture is distinguished by natural colors and unique patterns;

- naturalness of the material;

- possibility of carrying out restoration work;

- ergonomic use of space;

- variety of styles.

Drywall

One of the popular materials is, which is made from pressed wood chips. To create a dense composition, a thermoactive synthetic resin is used. This material is easy to process.

When working with plywood, it is necessary to take into account the softness of the material. Products may become deformed when twisted. It is recommended to use washers for such connections.

Laminated plywood is also popular. At the same time, plastic reduces the influence of formaldehyde in resins.

Furniture panels

The best material for homemade structures is furniture panels. This material is known for its durability, environmental friendliness and reliability.

It is worth noting the following advantages of using this material:

- does not require significant funds;

- you can bring unusual design ideas to life;

- the product can have different shapes and designs;

- For a furniture set, you can choose functional fittings.

Location of the wardrobe in the room

Before you start creating a wardrobe with your own hands in the hallway or in another room, it is worth considering its location.

If you place the set along a solid wall, then the furniture itself will be perceived as a wall. It would be better if the closet reached the ceiling. Doors can be mirrored, which allows you to visually enlarge the room.

If you place two identical cabinets along the wall and leave a distance between them, you will get an alcove. You can put or in the resulting niche. In the living room, an alcove can be used to create an area with a false fireplace.

A practical solution would be to install the headset along the edges of door and window openings. A mezzanine can be installed above the opening. The cabinet can be recessed into specially created niches. If the size of the room allows, then small sizes can be used.

Depending on the specific design style of the room, it is not necessary to make built-in wardrobes or disguise them. For retro or glam vintage style, bulky furniture will only complement the colorful design.

It is also necessary to choose the right drawer mechanism for the wardrobe. It shouldn't be noisy.

Hallway

Children's

There are many things that need to be placed in a child's room. These include seasonal clothing and shoes, children's toys, board games and sports equipment. In addition, you need to find a place for books, notebooks and bedding.

The sliding wardrobe is a spacious set in which you can place all your things and objects. The doors of this piece of furniture move apart to the sides, which does not take up much space.

Keep in mind that cabinet furniture is selected for children, so the shelves must be at the required height. It is important that there are no sharp corners at the ends of shelves and racks. Each thing must have a specific place, so the child will quickly learn order.

Note! When ordering externally, as a rule, it is not possible to control the consumption of material.

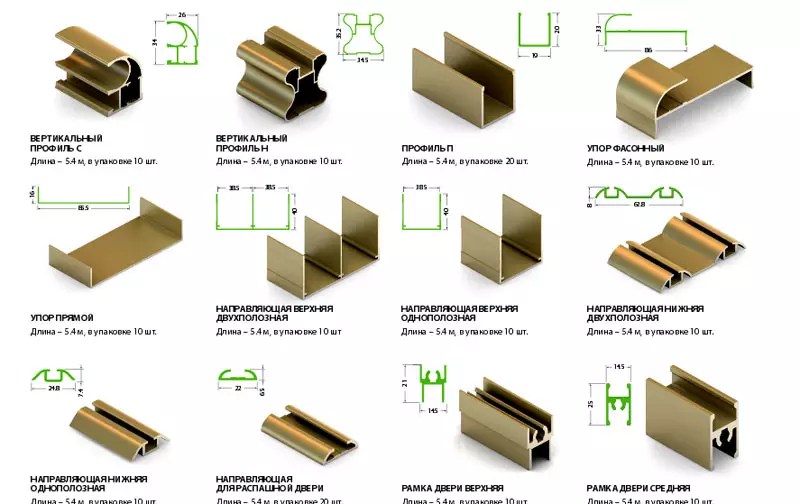

It is important to choose high-quality fittings; the correct adjustment of wardrobe doors depends on this. Doors should not jam or slide. Sliding systems consist of a profile and a sliding support. Roller mechanisms can be axial or bearing-based.

Choosing cabinet filling

The internal content helps decide what the layout will be. You should not place the section for outerwear in the center, as moisture from it can spread to the sides. It is better to place this compartment on the side. Boxes for bed linen are not recommended to be placed directly above the floor.

How to correctly arrange the elements and how to assemble a wardrobe with your own hands can be seen in the video below:

Number and sizes of doors, guides, rollers for wardrobes

When choosing guides for a sliding wardrobe, pay special attention to the material they are made of. The plastic profile has the lowest cost, but it is characterized by low reliability and short service life. The best solution would be to use combined rail guides, in which the supporting surface for the rollers is made of metal.

The steel profile for sliding doors has increased reliability. Rail supports for furniture of famous brands are made from aluminum.

The rollers are made of metal, since plastic is not durable. The roller contains a ball-bearing internal mechanism that allows the door to move freely in the horizontal direction.

Do-it-yourself wardrobe and compartment door assembly

We invite you to familiarize yourself with the process of assembling a sliding wardrobe with your own hands in the table below:

| Photo | Description of work |

| To assemble the wardrobe, you need to apply markings. It is necessary to note the dimensions of the cabinet in width and the location of the vertical rack. The heights at which the shelves will be fixed are noted. |

| Drill holes for dowels. |

| The profile is put on before installation. |

| Install a vertical stand. |

| We mark the mezzanine shelf and install it. |

| The side wall is installed. |

| The shelves are marked and installed. |

| The clothes rail is marked by size and installed. |

| False panels are installed. |

| One panel is fixed at the bottom. |

| The supporting upper part is attached. |

| The bottom guide is secured with a screw. |

| The top guide is attached in the same way. |

| Doors are being installed. |

The process is presented more clearly in this video:

Interesting solutions for sliding wardrobes: photo examples

Don’t forget about the decor of the furniture set. Pilasters can be used as decoration. These elements are made from solid wood or MDF. You can install a furniture cornice on the roof. Interior baguette is used for decoration. You can choose a baguette of different shades. Furniture with photo printing also looks stylish.

Article

It’s difficult to make a drawing of a corner cabinet yourself; our article will tell you the solution.

You can assemble a corner cabinet with your own hands if you try.

From our article you will learn about all the features of cabinets designed for corners and openings.

In contact with

Classmates

Peculiarities

A sliding wardrobe is the same wardrobe with hinged doors, but they are sliding. This saves up to 600 mm. space in front of him. By design they can be:

- Built-in.

At the same time, the structural elements of such furniture are the ceiling, floor, as well as the walls of the room. The most economical in terms of using living space.

Labor-intensive to manufacture due to poor-quality construction work. The installation of fasteners causes defects on walls and ceilings. It is no longer possible to move it.

- Hull.

They differ from built-in cabinets in their mobility and installation time. Protect the wall decoration from contact with the internal contents and doors.

Depending on where they are located inside the home, they can be straight, angular or radial. In turn, corner structures can be created:

- with a beveled corner facade with a hinged door;

- with elements located at an angle relative to each other;

- like two independent pieces of furniture installed in the corner.

- Radial.

Only a real idea of the technical advantages and functionality of the chosen design will give a tangible economic and aesthetic effect.

Creativity

The issue of coordinating and budgeting an event with stakeholders is not idle. Not only the technical and economic indicators of the designed furniture, but also the social aspects of family life directly depend on its solution.

Preparing a preliminary design is not as labor-intensive as the main process of creating cabinet or built-in furniture. But it is the accuracy of the developed drawings and diagrams that will be the fundamental stone of the entire event.

- roulette;

- plumb line, levels (not bad if laser);

- squares of various sizes;

- a flat wooden lath or metal profile for drywall.

First of all, we decide on the depth of the furniture. In practice, this size is taken to be 50 cm. Taking into account that 8-12 cm of them will be occupied by doors.

We carefully check the geometry of the location of the future furniture. We especially accurately measure:

- the size of the angle between the walls;

- curvilinearity and defects of walls;

- distance and parallelism of floor and ceiling;

- we take into account the minimum distance between them;

- horizontality, evenness, rigidity of the floor.

Note: To eliminate unnecessary material costs and increase labor intensity, even without taking into account moral damages, it is necessary to once again check the accuracy of all measurements and the performance of all accessories.

Based on the existing preliminary design and the obtained dimensions, we prepare the project itself, taking into account:

- Assembly sequences carried out on site.

- Ensuring the greatest strength and reliability of the structure.

- In terms of its internal content it must be functional.

- Ensure ease of installation and further use of built-in fittings.

- Between the shelves, a distance of no more than 40 cm will be rational.

- The height of the outerwear compartment is equal to the length of the clothing itself + 10 cm.

- The practical height for attaching the hanger rod is at shoulder level.

- The maximum height of the mezzanine shelf is 50cm.

- The layout of the racks of the lower compartment is carried out depending on the position of the doors, for ease of use.

- The same applies to drawers and baskets.

Material

Here, both decorative and technological aspects of the aspect should be taken into account. The financial side of the issue is also important. What to choose:

- Tree.

Traditional, and now even prestigious material. Its disadvantage is the possibility of warping when humidity changes. Alternatively, it may have a right to exist.

- Drywall.

It is difficult to classify it as a furniture material, but it can still be done. Can only be used in combination with a metal frame, this way you can build. The doors will be made of a different material. It is more of a building structure than furniture.

- Chipboard laminated or cached with decorative film;

- particle board of various densities and moisture resistance.

Children's furniture is made from grade E-1 boards.

- MDF (fine fraction) made of wood impregnated with a binder. It has found its greatest application in furniture making.

- Fiberboard (fibreboard), the same hardboard.

MDF boards and high-density laminated chipboard are the most suitable materials for furniture construction.

The most responsible approach should be taken when calculating the width of the sashes. Expert advice:

- The calculation is as follows: choose the largest door width. Determine the number of overlaps (1 less than the number of doors). Check the resulting width. If it doesn’t converge, we increase the number of doors. It is possible to change the internal layout.

- You can't make too many of them. It will just be inconvenient.

- You can't make it too wide - it will jam if it moves poorly. The most practical width is no more than 700 mm. The overlap of doors must be done within 50-70 millimeters.

- If there is more, it will be inconvenient to use the internal shelves. If it is less, cracks will appear and you will need to use the sashes with caution.

The narrowest shelf should be wider than the door, otherwise it will be inaccessible.

The practical implementation of the plan is the most interesting and exciting stage of all the work.

- Each of its technological transitions demonstrates real results of work. Of course, we check the availability of the required tool:

- - with drills (for confirmation - 4.5 mm);

- screwdriver;

- circular saw with ruler;

- hand saw;

- roulette;

- corner clamp;

- stapler;

- regular and soft hammer;

hex key for confirmat (furniture screw). You will also need confirmations D×L = 6.4×50 mm, self-tapping screws, furniture corners for shelves and wooden dowels.

- Technological points:

- Pre-cut and edged sheets of MDF or chipboard are marked for drilling holes for dowels and confirmats. The quality of assembly and the overall appearance of the product depend on the accuracy of the markings.

- Clamping and drilling of mutually perpendicular parts is carried out using an angle clamp.

- Drilling for confirmation is performed with a special confirmation drill. The option of drilling with two drills of different diameters followed by countersinking is possible.

The confirmations are tightened with a little force using a hex wrench. Take note:

- The choice of hangers for sashes is quite large, but the most practical among them are double-rail systems with a bottom support. The best is imported.

- At the same time, one should keep in mind the possibility of using both a two-rail system with an upper support and a monorail version.

Note from experts: With the top support, it is possible for the sashes to fall out, making their adjustment difficult. With a monorail support, the design and installation are complicated. Care is required during operation.

A cleverly designed and well-executed built-in corner cabinet will make the most inaccessible and neglected space attractive and comfortable. Made with your own hands, it will be a source of pride for a long time.

How to make a corner wardrobe with your own hands, see the following video:

In contact with

See inaccuracies, incomplete or incorrect information? Do you know how to make an article better?

Would you like to suggest photos on the topic for publication?

Please help us make the site better! Leave a message and your contacts in the comments - we will contact you and together we will make the publication better!

Corner is a structure installed between two walls.

With its help, you can benefit from free space and fill empty corners.

A distinctive feature of such furniture are sliding doors, which save space and add charm to the room.

Preparation

Shape and size

The shape of a corner wardrobe can be:

There are standard patterns and sizes for the manufacture of corner cabinets and non-standard ones. Standard patterns and sizes are:

As for non-standard products, it is advisable to install them in small, narrow and cramped spaces. When designing a drawing of a non-standard size corner wardrobe with your own hands, it is worth considering that:

- minimum depth the cabinet must be at least 35 cm. But the maximum permissible depth should not be more than 0.9 m;

- minimum width a non-standard piece of furniture should be at least 0.1 m. Then the doors will have a width of 45 cm. Narrower doors will be inconvenient to use and unstable;

- height There are no restrictions on non-standard products. Depending on the wishes and requirements of people, cabinets can be made as high as the ceiling. But the optimal comfortable height is 2.1 – 2.4 m.

Interior arrangement

When designing furniture, it is worth considering proper zoning of space. Namely, you will need:

When designing furniture, it is worth considering proper zoning of space. Namely, you will need:

- shelves for things. They are the main filling element. They can be made stationary or retractable, solid, ventilated, half or full depth;

- rails for shirts and other short items. Most often they are made of metal;

- hooks for bags and robes;

- shoe shelves. In the upper part of the mezzanine it is convenient to store shoes in boxes;

- drawers for underwear and socks;

- trousers. Their trousers will always be ironed and ready to put on;

- tie bar. It will make it convenient for you to select products. They will not wrinkle or lose shape;

- belt hooks;

- pull-out baskets for small things. All things will be visible in them. It will be convenient to store bracelets, glasses, watches in them. The inside of the basket can be divided into separate cells.

Scheme and drawing

After you have decided on the size, shape, materials and design of the cabinet, you should draw a diagram indicating all the internal compartments, drawers, and shelves.

Advice. If you own a PC, you can make a sketch using a special program. With its help, both simple furniture elements and quite complex ones are created.

When creating a project for future furniture, it is important to consider:

- product dimensions;

- dimensions of the door, base and cabinet lid;

- materials and dimensions of the rear part;

- internal space - vertical and horizontal sections, drawers, shelves;

- the presence of mezzanines;

- arrangement of accessories.

Materials and tools

An important criterion in the manufacture of furniture is the choice of consumables. For the manufacture of the frame the following is used:

- natural wood. Wooden products are the most durable and environmentally friendly. Such furniture will delight owners with its natural beauty, interesting texture and texture. But its cost will be quite high;

- MDF. This material has good performance characteristics, durability and affordable cost. Distinctive features of MDF are its ease of use, environmental friendliness and safety, excellent decorative qualities;

- laminated chipboard. It is distinguished by practicality, durability, reasonable cost, moisture resistance and aesthetics. Modern manufacturers provide a wide color palette of laminated chipboard. Thanks to this, stylish and original furniture pieces are obtained.

Doors can be made from:

- wood;

- plastic;

- MDF or chipboard;

- tempered glass.

Important. The durability of structures directly depends on the driving mechanisms. Therefore, special attention should be paid to the choice of fittings and guides. There is no need to skimp on these materials. It is recommended to purchase products only from well-established manufacturers.

To assemble a cabinet according to the finished project, you will need the following tools:

To assemble a cabinet according to the finished project, you will need the following tools:

- hammer;

- screwdriver;

- drill;

- square;

- pencil.

Also, before installation, check the availability of:

- finished drawing;

- furniture board;

- guides and fittings;

- drawers, shelves, hangers, handles;

- dowels and screws;

- upper and lower false panels.

Manufacturing

How to make elements?

Having in hand a project for a corner cabinet with all the calculations, you can go to a company where they will cut out the materials for you.

If you decide to make all the details yourself, you need to:

- Cut out all the elements of the product from sheet material: walls, doors, shelves, drawer elements. You can make the parts using a circular saw. It is also possible to cut with a hacksaw, but in this case chips may appear on the parts.

- After this, we process the edges using PVC edge tape of a matching color. Trimming the cabinet elements can be done using an iron or a hair dryer.

- We apply the trim with the adhesive surface to the part and iron it with an iron or heat it with a hairdryer.

- We run a soft cloth along the edge, pressing it tightly against the product.

- We cut off the remaining tape with a knife.

Assembly of the structure

The corner cabinet can be built-in or cabinet. The assembly process for different structures is slightly different.

The corner cabinet can be built-in or cabinet. The assembly process for different structures is slightly different.

To assemble a built-in product, there is no need to install the back wall and corner ends. The product assembly process will consist of the following steps:

- If necessary, we process and level the walls in the room. We paint them or cover them with wallpaper.

- We drill holes in the places of future fastenings.

- We connect all the parts of the body.

- We check the work done using a level.

- Next we move on to the interior arrangement. We mark the location of the internal shelves of drawers and sectional partitions.

- We install doors.

Frame of a cabinet product is assembled according to the following principle:

- We make markings at the location where the piece of furniture will be installed.

- We assemble a special device from a metal strip and two pieces of board connected at an angle. You will also need 2 quick-release clamps. Using these tools, it is convenient to connect workpieces at right angles.

- We check the parts with a square and measure 7 cm from the top edge.

- We make marks for drilling on the upper and lower parts and drill the parts.

- Using a screwdriver, tighten the confirmat.

- After fixing the sidewalls, we place the location of the shelves and make holes for them. We install the crossbar and screw all the shelves.

- Next, we assemble the lower part of the furniture piece.

- After assembling the cabinet, a sheet of fiberboard is attached to the back of the cabinet using furniture nails.

- We install the door.

Door installation

The last step in assembling a corner cabinet with your own hands is installing the doors. They should be ordered separately from a company that deals with similar systems.

The last step in assembling a corner cabinet with your own hands is installing the doors. They should be ordered separately from a company that deals with similar systems.

Sliding systems consist of the following elements:

- top guides;

- lower guides;

- the top of the door;

- bottom of the door;

- vertical stand for side parts;

- sealing rubber. It not only softens the opening and closing of the structure, but also prevents dust from entering;

- sets of upper and lower rollers;

- brackets for securing doors.

- vertical side profiles. They can be symmetrical or asymmetrical.

- door filler (mirror, wood, glass). Performs a purely decorative function, adding originality to the overall interior of the room.

Important. All door components must be covered with a protective film to prevent damage and scratches during delivery.

Door assembly instructions as follows:

Door assembly instructions as follows:

- We place the door in a horizontal position so that it can be accessed from all sides.

- In the upper part of the vertical stand we make two holes for fastening - the bottom hole will have a diameter of 6.5 mm, and the top hole will have a diameter of 10 mm.

- At the bottom we attach a roller.

- We insert a rubber seal into the upper part of the mirror and fix it with a profile. We lay the seal around the entire perimeter.

- Next, install a vertical profile with a handle.

- We join the upper profile to the cross member and tighten the screw with a hex key. The screw is not screwed in completely, since the upper rollers will be installed into it later. Only after this is the screw tightened until it stops.

- Next, install the lower profile and tighten it with a hex wrench.

- We put on the final vertical profile and tighten the screw with the upper roller.

- We prepare everything for installing the lower roller, tighten the spring and carefully insert the roller into the drilled hole. We secure everything with a screw.

- Fix the top guide. We do not screw the bottom guide.

- We insert the lock for the door and set everything to the level. Only after checking that a gap of the same width is formed on the outside when the doors are closed, do we fix the lower guide with screws.

Instead of struggling with choosing furniture for a small apartment, it’s better to learn how to make a corner wardrobe with your own hands. After all, no matter how little space there is, the corners in the hallway, kitchen, and rooms remain empty. A hand-made cabinet will not only solve the problem of placing things, it will elegantly decorate the interior.

Design

There is no exemplary standard design that a corner wardrobe must comply with. It can be built-in (when you only need to install doors) or cabinet-mounted, have different sizes, different numbers of sides (triangular, trapezoidal, L- or U-shaped).

In recent years, a radius sliding wardrobe has become popular, which is a furniture structure devoid of sharp corners. Lovers of beauty will undoubtedly appreciate the curved doors that slide along the corresponding profiles. This layout allows you to save space and elegantly solve the problem of storing a large number of things.

In Fig.2. angular are diagram No. 1 (concave), No. 2 (convex), No. 5 (convex column of a massive furniture structure or a free-standing small wardrobe). All other options for radius sliding wardrobes can be obtained by combining the 6 initial types listed above.

Radius is beautiful and functional

The movement of the radius cabinet doors is smooth and almost silent. Similar characteristics are provided by the profile included in the sliding mechanism. Manufacturers offer it in steel or aluminum. We recommend choosing the second option for the following reasons:

- increased resistance to damage;

- minimizing noise when the door slides.

The cost of an aluminum profile is higher than a steel one. However, over the course of long-term use, you will appreciate your choice.

The wall thickness must be at least 0.12 cm. A thicker profile increases the reliability of fastening. High-quality components are produced by Komandor, Absolut, Raumplus, Aristo, and others. If the height of the radius cabinet is above 3 m, we recommend taking the Raumplus profile.

The doors of a radius sliding wardrobe can be with an upper sliding system or with a lower one. In the first case, the doors hang on rollers. Movement is carried out along the upper guide. The initial impression of the suspension system is excellent. However, the large load on the upper horizon causes its gradual sagging. The hanging system wears out quickly and, without regular maintenance, can unexpectedly lock the door at the most inopportune moment.

The second sliding system looks preferable for daily household use. The sash slides along the bottom guide, the door is attached and fixed along the top. The load is distributed evenly, the assembled structure will last longer.

Door elements

Assembling corner wardrobes with your own hands without a diagram showing the exact dimensions is impossible. Particular attention must be paid to the moving part of the structure - the doors. You cannot miss anything or take the wrong size; in such a case, the doors will not be able to be used normally.

Before assembling your closet, let's take a closer look at the elements of doors with a bottom sliding system:

- Vertical side profiles can be symmetrical or asymmetrical. During operation they are used as handles. Symmetrical profiles look the same on both sides, while asymmetrical ones create a difference between the outer and outer sides.

- The asymmetrical rollers located at the top are designed to fix the sashes in the opening.

- The upper door frame is necessary for attaching wheels to it, as well as for subsequent fixation of the structure.

- The lower door frame is used to install the lower wheels and ensure proper sliding of the doors.

- The internal door filler (wood, glass, mirror) performs a decorative function and gives the entire interior a personality trait.

- The seal attached to the vertical side profiles, in addition to softening the impact of the door on the cabinet wall, protects the moving structure from dust.

- The door plug is used to secure the side vertical profiles.

- The assembly and adjustment screws allow you to change the sliding speed of the sashes.

- The stopper makes it possible to fix the door and avoid unintended opening of the doors.

Calculation of cabinet capacity

Any step-by-step instructions will give you confidence in the work you have started, but without a preliminary assessment of capacity, the result will be disappointing. Before drawing drawings and studying the assembly manual, decide what you will put on the shelves or hang. Then it will be difficult to move the functional sections; a beautiful-looking cabinet can become a source of bad mood.

- to arrange things according to the season, provide at least 2 sections for outerwear;

- when installing recessed lamps, the upper horizon of the cabinet is moved forward by 12-17 cm;

- not only convenient, but also functional when the depth of the shelves is at least 60 cm;

- shelf widths of more than 65 cm increase the risk of them sagging;

- the intershelf distance should be no more than 35 cm;

- accept a door width of 50 cm; smaller sizes may cause the guides to fall out;

- the number of functional compartments should be proportional to the number of sashes;

- When designing the dimensions of drawers, pay special attention to the location of the door frames; if they are too wide, it will be impossible to reach them;

- doors must be the same width;

- The appearance and strength of the cabinet depends on the thickness of the chipboard;

- The material for the roof, side walls, and doors will be chipboard; the back wall can be made of fiberboard 3 mm thick.

The most practical option is to make a built-in radius wardrobe. This design will easily blend with the walls, hide possible defects, and require less material consumption and time. Housewives will appreciate the absence of gaps between the wall and the cabinet, where dust constantly accumulates

Assembling the closet

To install the designed cabinet you will definitely need:

- screwdriver;

- hammer;

- square;

- drill;

- pencil.

Before you begin assembling the structure, also make sure you have:

- drawings;

- furniture board 18 mm;

- doors and guides;

- “insides” of the cabinet (drawers, hangers, handles);

- door fittings, screws, dowels;

- side, bottom and top false panels.

Step-by-step assembly order:

- Taking measurements and drawing “on the ground” where the cabinet will be installed (you will need a pencil and a level). Vertical posts are marked on the wall, profiles are marked on the floor and ceiling.

- Determining the location for the shelves, drilling holes for the dowels, hammering them in with a hammer.

- Fastening profiles for shelves to the wall, installing their lower holders.

- Marking the mezzanine shelf and fastening it with self-tapping screws.

- Adjusting the side wall to size and installing it.

- Installation of internal “filling” (shelves, drawers, etc.).

- Installation of pre-prepared false panels, attaching them with a screwdriver to the floor, ceiling, side wall.

- Cutting and bending the upper and lower profiles (don’t forget to insert 1 stopper per door), attaching them with screws to the false panel.

- Installation of the assembled door. The description of the actions is as follows:

- decorating with self-adhesive film (if necessary),

- installation of vertical profiles with screws,

- installing a door seal,

- securing the upper and lower door frames,

- attachment to the bottom and top of the rollers,

- inserting the top guide, then the bottom,

- checking the correct sliding, adjusting it (if required) with a hexagon.

The sliding wardrobe, invented in the USA, has become widely used as the main type of storage for household items and clothing. In our country, this type of furniture appeared only in the middle of the last century. This is surprising because many of us have lived in small apartments where its benefits are obvious.

Domestic craftsmen were in no hurry to make a wardrobe with their own hands. The reason is that the cabinet version, except for sliding doors instead of casement ones, has no other advantages over the usual wardrobe.

It is much easier to make a built-in wardrobe with your own hands. Its manufacture will require significantly less material, and even an inexperienced carpenter can make such a compartment on his own. With a smaller footprint, this storage option will have a larger volume than a cabinet storage option.

Sliding wardrobe design: distinctive features

The sliding doors of the first wardrobes produced by our industry did not have rollers for movement. At the bottom there was a longitudinal tenon along which the door moved, which had a groove along the lower end.

This simple design was quite reliable. Its disadvantage was that moving the doors required great effort, because the cabinet itself and the doors were made of heavy material, which was chipboard at that time.

You can make a sliding wardrobe with your own hands, built-in or in a regular mobile version. You can also make a corner cabinet yourself, either built-in or cabinet-mounted.

A corner wardrobe with your own hands must be made in relation to a specific place.

In plan, it can have the shape of a triangle, trapezoid, L or U-shape. Among other types, five-walled can be distinguished. This design has the shape of a pentagon with 3 right and 2 obtuse angles.

This diversity is the versatility of a corner wardrobe. If everything is clear with other forms, then the five-wall requires clarity. This version of the sliding wardrobe, occupying a slightly larger area, is much more spacious than, for example, a triangular analogue.

Stages of preparation for making a five-wall

When making a wardrobe with your own hands, do not try to saw the sheet material from which the side walls and doors will be made at home. It is almost impossible to manually achieve the required dimensional accuracy, especially for a corner wardrobe. Having decided on the dimensions of its sides and doors, it is advisable to use the services of a workshop where it is possible to ensure the required cutting accuracy. It is also advisable to process the ends that will be visible from the outside. The elements located inside the cabinet can be made independently.

Before making a corner compartment with your own hands, check the installation location. This is especially important for the built-in option. Any unevenness in the floor or ceiling where the doors will move must be corrected. Otherwise, there will be problems with installing guides for moving doors.

Make sure that there are no electrical outlets or other elements that could affect the installation of the wardrobe yourself. Consider the size of the baseboards and, if any, moldings on the walls under the ceiling.

It is not advisable to save on a sliding door system. More expensive Italian or German designs will pay for themselves due to reliability and long-term operation.

There is no point in showing the specific design of the carriages. There are quite a lot of them, and each of them has its own installation characteristics. First you need to figure out how to install: the dimensions of the cabinet elements will depend on this. A more reliable option is for doors with an upper running carriage. At the bottom of the door there will be a roller moving along a guide.

Before you start making a sliding wardrobe with your own hands, you should have the appropriate tools. When making a built-in version, a hammer drill is required. You will need a power tool to screw in the screws. It is advisable to have a hand-held circular saw with a guide fence. A hand saw will also work.

You will need an angle clamp, a tape measure, a stapler, a soft and hard hammer, a drill with a set of drills, and a hex key for screwing in confirmations. To drill confirmation holes to a given depth, you will need confirmation drills. For simple drills, a stopper can be used.

It is necessary to purchase dowels, supports for shelves and screws.

Drilling holes in chipboard is the main operation when assembling furniture

To fasten panels made for furniture from chipboard, confirmats are used. Typically, confirmats with dimensions D×L = 6.4×50 mm are used for furniture. This mount has d=4.4 mm. The hole diameter for it should be in the range of 4.5-5 mm. With a larger diameter, the fastening will not be reliable; with a smaller diameter, the confirmat can destroy the fiberboard material.

To drill holes, special drills are used, which drill to a depth L and provide the appropriate dimensions in the upper part of the confirmat (H and h). Then the surface of the slab is countersunk to fit the cap. Screw in the confirmation without putting much effort, using a special hex key.

3 drilling options:

- drilling through the entire thickness;

- drilling in the end;

- drilling in 2 parts at the same time.

Another, most difficult option is drilling for dowels. The general condition for all types of drilling is the perpendicular position of the drill to the surface.

Let's consider the option of drilling in 2 parts. The parts are placed next to each other and secured using an angle clamp or other device. After this, marking and drilling are performed. This option is the fastest and most accurate. To determine the mark based on the thickness of the chipboard, it is advisable to make a template from wood or aluminum corner. If the chipboard thickness is 16 mm, then the center of the hole in the template should be exactly in the middle.

If the parts are connected in such a way that the holes are drilled separately, then the strength of the fastening depends on the accuracy of the markings. This is how you have to drill when connecting parts to dowels. For example, to install a cabinet lid on dowels, holes are first made in it using a drill with a diameter of 8 mm with a limiter that does not allow drilling through it. Holes from the edge of the cover are drilled taking into account the indentation of the sidewalls, if provided. Using the same drill, holes are made in the sidewalls to a depth of 20 mm. The accuracy of the marking determines whether the dowels will fit into the holes. The ends of the dowels are placed on glue. When assembling, craftsmen do not recommend pouring glue into the holes on the lid; you may have to disassemble the cabinet.

It is especially easy to assemble a built-in wardrobe, which will have only 2 sides, fixed perpendicular to the wall. These parts are securely attached to the ceiling, floor and wall using corners. The corner is secured to the base using plastic dowels and self-tapping screws. The sidewall is secured to the corners with self-tapping screws. It is between these elements that the door movement system must be secured.

With proper preparation, there should be no problems with assembling the cabinet.