And cable lines, you often have to solve the problem of how to pass a wire or cable through the outer walls of buildings and internal partitions. There are many requirements for the passage of electrical conductors through obstacles, and it is very important to comply with each of them, because this affects not only the ease of repair and replacement of wiring, but also the safety of its use. In this article we will tell you how to lay cables through a wall made of wood, brick and concrete in accordance with the requirements of regulatory documents.

Gasket requirements

The requirements for this type of work are regulated by two main regulatory documents. The first source is the PUE, which should always be consulted when it comes to installing electrical installations. The second document is SNiP 3.05.06-85, which describes the standards for the construction and installation of electrical devices. Information on this issue is also contained in Federal Law 123, formulating fire safety requirements.

For the production of construction and installation work a corresponding project is required. If it is intended to lay a cable or wire through walls, the project must contain an architectural and construction part. The openings that a wall or partition must have through which wires and cables are supposed to be laid must be indicated on the project drawings.

Openings (openings) made in accordance with the design in walls, partitions, ceilings and foundations should not be framed by weakened areas that may collapse during operation. In general, installations through walls must meet the following requirements:

- the laying must provide the ability to replace wires and cables during operation.

- When installing wiring, it must be ensured that fire, smoke and moisture cannot spread through the installation openings from one room to another.

Compliance with these conditions is ensured by observing the following rules:

- Laying of cables and electrical wiring through fireproof walls and ceilings is carried out in pipes, ducts or directly in openings. At the same time, only protected (armored) cable can be laid in openings, without the use of additional protection. We talked about this in a separate article.

- If the wall, partition or ceiling is made of combustible material, conductor products are laid in steel pipes.

- The space between the wires and pipes or boxes, as well as all backup openings and boxes, are sealed. We also talked about that.

The material used to seal openings must be easily removable if necessary. The fire resistance of the sealant cannot be inferior to the fire resistance of the wall, partition and ceilings. Sealing with a sealing material is carried out on both sides of pipes, ducts, and openings.

If the cable passes through the wall in a section of pipe, its bending radius, if any, should not exceed the permissible bending radius of the conductor grade used (this parameter is indicated in the technical specifications).

Installation technology

First, let's look at how to run a power cable or wire through a wall. wooden house or log buildings.

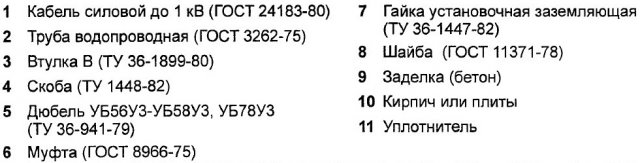

The first step is to determine the entry point where the wall is drilled. The hole diameter is determined based on the thickness steel pipe, into which the conductor will be placed. Before stretching the cable, its edges should be carefully processed with a file to remove sharp burrs that could damage the insulation. For additional protection of the cable line, it is better to lay it in corrugation.

After installation, the pipe filling requirements must be met. In this case, you can use an asbestos cord, wrapping it around the cable and driving it tightly into the pipe on both sides. The photo shows wooden wall and laying the power cable through it:

How to conduct electrical wiring through the wall and perform wiring is shown in the photo below:

- Steel pipe.

- Distribution box.

- Asbestos cement lining.

- Cable channel.

- Corrugation.

- Asbestos cement lining.

- Double socket.

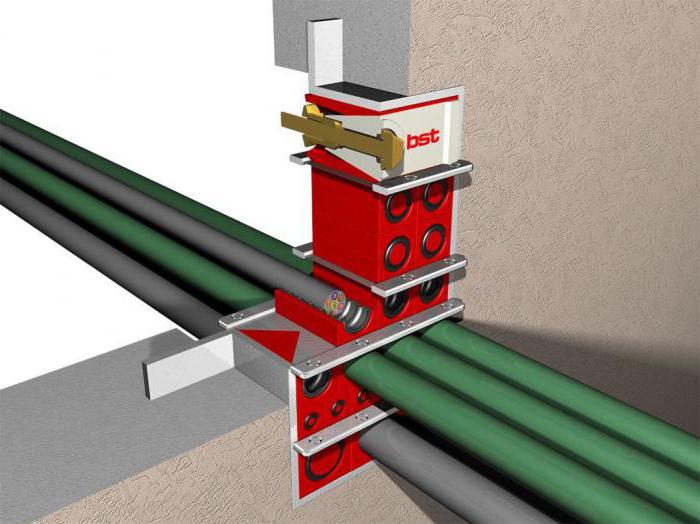

For example, the options for how to route a cable through a brick wall are shown:

The sequence of work is as follows:

- IN brick wall an opening of the required dimensions is made.

- A piece of corrugation (sleeve) is inserted into the prepared opening.

- A heat-shrinkable seal is installed on the pipe.

- The space between the sleeve and the opening is filled with mortar.

- A cable or wire, previously placed in a corrugated pipe, is passed through the sleeve.

- The space between the corrugation and the sleeve is sealed with one of the materials that meets the requirements of the rules.

- By thermal exposure (for example, using a hair dryer), the seal shrinks until the entry point is completely sealed electrical conductor into the sleeve.

If the wall is made of concrete, the technology is the same as for a brick one. The photo below shows an example of laying a cable through a concrete wall.

|

|

Characteristics

|

||||||||||||||||

|

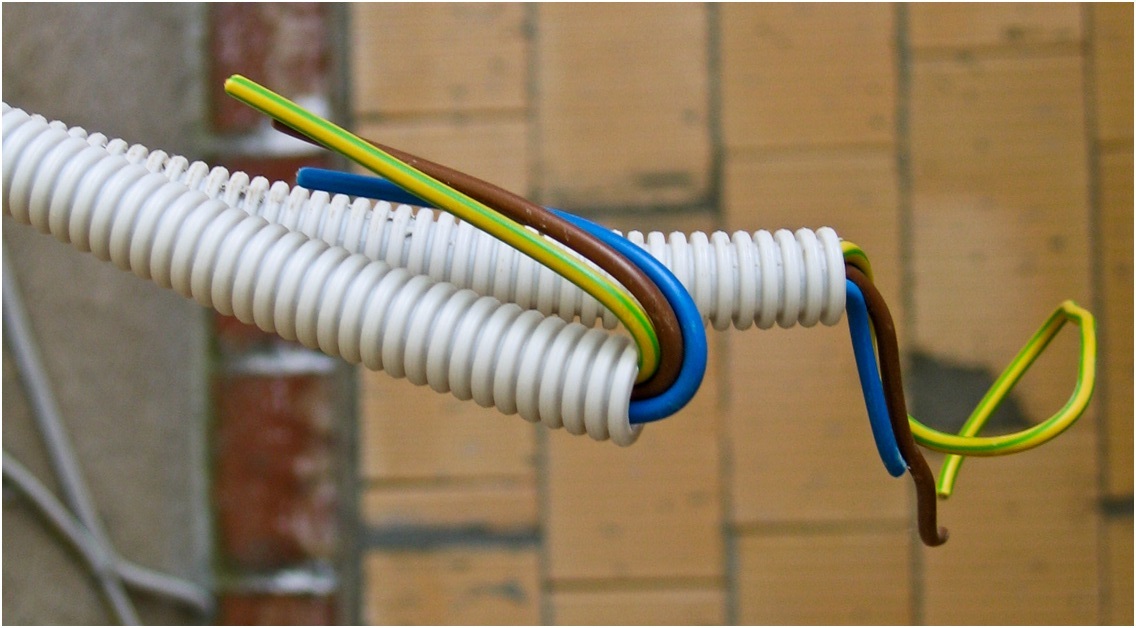

PRODUCT DESCRIPTION: Cable penetration OGNEZA-PM-K 40/20 is used for sealing the passage of process pipelines, pipelines engineering systems, cables and cable systems through walls, ceilings and others building structures. In the event of a fire, penetrations prevent the spread of fire and smoke into adjacent rooms. |

|||||||||||||||||

Scope of application of cable penetration OGNEZA-PM-K 40/20

Cable penetration OGNEZA-PM-K 40/20 is used to block the spread of fire along cable communications through walls and ceilings with standardized fire resistance limits.

Advantages

- High fire resistance

- The coupling body is detachable and equipped with a tie-lock, which allows it to be used on already laid cable lines and simplifies installation and dismantling of the product.

- All metal parts are painted powder paint, which reliably protects the product from corrosion.

- The fire retardant liner begins to operate at 15 seconds, at a temperature of 150C

- The service life of the universal cable penetration is 30 years at temperatures from -50 to +80C

Transportation and storage

The components are supplied in a box. The weight of the packaging unit is no more than 15 kg. Transportation and storage at temperatures from -50C to +60C. Transportation can be carried out by any type of transport that ensures the safety of the container.

- Cable penetration is used for cable lines laid both in a metal embedded pipe and without it, through walls with a thickness of at least 150 mm.

- Suitable for both single cables and bundles of cables.

- Cable couplings are mounted on both sides in a metal sleeve in the wall or ceiling along the laying of cable lines. If there is no sleeve, the coupling is mounted in a hole previously sealed with mineral wool material.

- The coupling is mounted with its body inside the wall or ceiling, or outside, depending on the chosen installation method.

- The coupling is attached to the wall or ceiling with metal dowels or anchor bolts.

- The coupling body is detachable, which makes it easy to dismantle and replace the cable penetration.

Cable penetration "OGNEZA-PM-K"40/20 serves to prevent the spread of fire and smoke through walls and other ceilings. It is made of durable material and is coated with high quality powder paint to prevent premature rusting. The response time interval is 15 seconds. when the temperature reaches +150°C. After four minutes, OGNEZA completely shuts off and holds the flame for 3 hours. Fire-resistant cable penetrations, they are installed on any objects that have cable lines. Protect your home from sudden fire!

In accordance with fire safety requirements, when laying any communications, cable penetrations must be constructed - products, prefabricated structures that are designed for the passage of cables, pipelines, communication lines through walls and partitions. Their main purpose is to prevent fire from spreading into adjacent rooms through flammable materials. They are arranged on the basis of SP 2.13130.2009 and GOST R 53310-2009. Their installation is mandatory and regulated by Federal Laws.

Fire compartments and cable penetrations

According to fire safety requirements, during the construction of buildings residential buildings they are divided into fire compartments, which block fire and smoke on their territory and prevent them from spreading beyond the compartment. However, utility lines pass through any room, which violate the integrity and tightness of the fire section. In order to maintain the fire resistance limits of the structure, cable penetrations are installed.

A striking example that proves the need to install such structures is the fire at the Ostankino TV tower in 2000. Here, telecommunication lines were placed in a vertical shaft, without dividing it into fire compartments and laying protective passages. As a result, the fire quickly spread throughout the building.

Design of cable penetrations

The simplest cable penetration is a metal sleeve embedded in a wall or partition. A cable or pipeline passes through the sleeve, the outer diameter of which is slightly less than the diameter fire protection structure. The gap between the communication line and the inner wall of the sleeve is filled with tow, thoroughly soaked in fat. That is why the simplest cable penetrations are also called glands. Also, along with or instead of tow, asbestos, rubberized rings, and special packings can be used.

At industrial facilities and power plants, slightly different structures are installed. They are two ends of which are connected by sleeves. To seal the gap between communications and internal walls, special diaphragms and washers are used. One such cable penetration is used to pass several utility lines.

Sealing materials

To create the possibility of laying an additional or replacing an old utility line, all wires, cables and other communications pass through the walls in boxes or trimmings metal pipes(sleeves). Therefore, the sealing of cable penetrations must be made of fire-resistant, water- and gas-tight material that is easy to remove.

In this case, the ability of the embedding to resist fire should be no lower than the fire-resistant ability of the wall.

SNiP 3.05.06-85 specifies specific mixtures that can be used to fill the gap between the cable and the penetration:

- cement-sand mixture in a ratio of 1:10;

- composition of clay and sand with a material ratio of 1:3;

- sealing mass of clay, sand and cement (1.5:11:1);

- gypsum and expanded perlite, taken in a ratio of 2:1;

- other materials that meet fire safety requirements.

Cable penetrations are also allowed to be sealed construction foam, if it is certified in accordance with the requirements of GOST R 53310-2009. Gaps in the walls do not need to be filled if the partitions are not fire barriers.

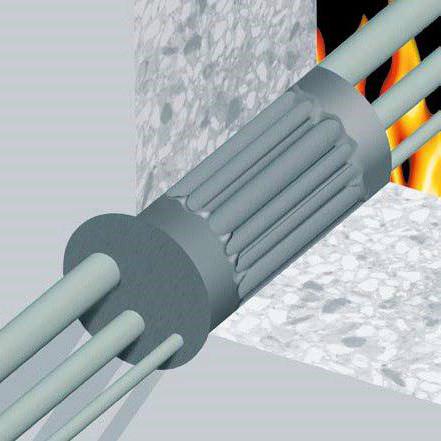

Modular penetrations

IN modern construction Modular penetrations are used to isolate fire compartments. They are steel or plastic frames, which are equipped with blind inserts or modules with holes. To protect against electromagnetic radiation, copper gaskets are installed. The tightness is created by tension bolts.

IN general view modular cable penetrations for fire protection are complex design, assembled on site from prefabricated sealing inserts made of a polymer that is difficult to burn. Elements made of galvanized high-grade steel are used as fastenings.

In this penetration, the cable is placed in a special sealing module and crimped with an adapter for increased tightness. When the tension bolts are screwed in, the sealing inserts are compressed, tightly compressing the cable and ensuring gas- and water-tightness of the penetration.

Features of installation of cable penetrations

Installation of penetrations has its own characteristics, which depend on the type of material load-bearing structure. Thus, when laying cable systems in monolithic concrete buildings, fire-resistant structures are laid directly into the formwork before pouring concrete mixture. When constructing prefabricated monolithic buildings, penetrations are laid into blocks at the factory during their manufacture.

In brick houses, for installation, cable systems are placed in special channels - grooves. Small holes are drilled in finished monolithic buildings. The diameter of the penetration is calculated separately. During construction or temporary operation of a building, penetrations are made of special fireproof cushions.

Cable Penetration Testing

Depending on the location of operation, cable penetrations must meet established requirements. Thus, when they are installed at nuclear power plants, they must be tested for their ability to absorb, insulate or reflect radiation.

At ordinary construction sites, universal cable penetrations are tested by heating, force (mainly on bending resistance), as well as fire resistance, water and gas insulation properties.

286

286