A roof with two slopes over garages is built a little less often than a single-slope analogue. Although, according to a common misconception, one slope requires less costs, a “house” structure is often cheaper to build. Water flows freely from its inclined surfaces, so there is no point in laying multi-layer waterproofing.

There is no need to install parapets that increase the consumption of materials. The simple construction process is quite accessible to the home craftsman if he knows how to construct a gable roof for a garage in strict accordance with the technological instructions.

Houses for four-wheeled “horses” are equipped with exactly the same types of roofs as the houses of car enthusiasts themselves. There are practically no differences in the technologies for constructing pitched structures for garages and residential buildings.

The height is determined by the preferences of the owners and their plans for using the roof space. You can freely organize a workshop, a rest room or a warehouse in it, if the load-bearing capacity of the box does not cast doubt on the strength aspects.

A steep roof will require more funds for arrangement than its low counterpart. Its slopes are more substantial in size, and the elements of the rafter frame are more impressive. Therefore, even among domestic owners of brick and concrete garages, there are not too many lovers of tall structures if the use of the attic is not planned. They view the need to regularly clear snow from a low-pitched roof very favorably, as a good reason to visit the garage one more time and put things in order in their personal possessions.

An insulated gable roof of the garage will significantly save heat. However, without convincing climatic indicators in the construction region, it is unreasonable to improve the heating technology of a building. If necessary, heat-insulating material is laid between the rafter legs, protected from below with a vapor barrier film, and from above with waterproofing.

The work is carried out in accordance with the rules for constructing conventional pitched roofs; rafter systems can be made of either wood or galvanized metal.

Depending on the design data of the box being equipped, the following is used in the construction of rafter systems over garages:

- Layered technology, according to which the upper and lower edges of each rafter leg have its own reliable support. The bottom of the layered rafters usually rests on the walls of the building. The top is placed on a strong purlin system, which in turn is supported on an internal wall or a series of support pillars inside the garage. The construction of a layered rafter system begins with the construction of a frame topped with a ridge girder. It is on the frame that the tops of the rafters installed in pairs rest.

- Hanging technology, according to which the rafters rest only on the walls of the box. The fulcrum for the upper heel of the hanging rafter is a similar part of the mirror-deployed fellow. Rafter systems of the hanging variety are constructed mainly by installing triangular trusses, the base of which most often serves as a ceiling beam, less often a screed located above. Trusses can be purchased fully prepared for installation or made independently.

Rafter systems of the layered variety are built over garages if there is a need to cover a large span. For example, in garages with two or more car boxes. These structures usually have at least one wall or a series of support posts to support the roof structure. The hanging scheme is ideal for erecting a roof over a building designed for one car. Internal walls and support pillars in small buildings are unacceptable due to the small size of the usable space.

Both types of rafter frames when covering small spans up to 5 m include a minimum of elements. The layered system consists of rafter legs installed in pairs and a purlin structure, while the hanging system consists of a number of rafter trusses. As the spans increase, it becomes more complex and is supplemented with struts, support pillars, additional purlins, headstocks, crossbars, etc.

Note that for a roof with two slopes, the construction of a rafter frame is not a prerequisite. The slopes can be formed by triangular pediments. On the sloping sides of the gables, beams are laid - beams parallel to the ridge girder and overhangs. The rafterless technique is practiced mainly in wooden construction. It is still customary to equip brick and stone buildings with pediments using roof trusses installed inside the box.

Garage roof construction technology

The simplest way to obtain information is a thorough analysis of construction methods and technologies. For those who want to know how to build a garage with a durable gable roof on their own, we offer several of the most common examples. We will consider the construction of roofs over frame walls. Their specificity lies in the fastening of the rafter system to the upper frame of the wall supports, and not to the Mauerlat of brick and concrete garages. The difference is not fundamental, but you should not forget about it, especially at the design stage, because The embedded parts for attaching the Mauerlat must be laid during the construction of the walls.

The final roofing covering for garages is chosen based on the steepness of the structure and on your own economic considerations. The material from which the walls are made is not of serious importance. In the arrangement of low-slope buildings, mainly rolled materials are used, which attract owners with their excellent water-repellent qualities.

For the roofing of higher roofs, metal tiles or economical ones are used, which please not only with the price, but also with the ability to lay the covering yourself. Ceramic tiles and natural stone above domestic garages are extremely rare, and then only if uniform landscape requirements are imposed on the site.

Layered garage roof options

An example of a gable roof over a “single” garage is quite accessible to an inexperienced performer. The roof is cold, but if desired, this aspect can be thought through and finalized yourself. The width of the board from which the rafter legs of the insulated roof will be made should be selected so that the thickness of the insulation is 3-5 cm less. This difference is needed to form ventilation flows that remove evaporation and condensation from the insulation.

If purchasing boards of the required size does not work out, a sheathing is nailed on top of the rafters - a block that increases the missing width.

The simplest rafter structure

Step-by-step instructions for craftsmen who decide to build a cold gable garage roof with their own hands:

- We mark along the top trim of the long walls of the garage. We note the installation step of the rafters, which according to the project is 40 - 60 cm. In short, we simply divide the wall into equal sections, the length of which is not less than 40 cm, but not more than 60 cm. We mark from the corner of the box, do not forget that the outer pairs of rafter legs must be installed flush with the end walls.

- We install ceiling beams. According to the markings, we install the board on both walls. She must lie on her edge strictly horizontally. We check the horizontality with a level gauge and fix it with a pair of nails or corners. Ceiling beams, along with the main work, play the role of tightening, compensating for the expansion. If you need to inexpensively insulate a building, then it is better to place the thermal insulation between the ceiling beams, providing the inside with a vapor barrier film and additional sheathing.

- We lay pieces of plywood or similar material along the installed ceiling beams to provide access to the rafter frame construction site.

- We mark the middle of both end walls and place a mark on the top trim. We temporarily nail the rail to the ends so that one of its faces coincides with the conditional central axis. An auxiliary rail is needed to accurately determine the position of the ridge and to make rafter templates.

- We apply the board from the end to the installation site of the outer rafter leg. We mark the cut lines as they happen. This is a template, we use it to make the rest of the rafters with equal sizes and cuts.

- Focusing on the auxiliary slats, between which it is advisable to stretch the cord, we install supports under the ridge girder. When constructing long-span structures, we install supports every 120 cm. Having checked the verticality, we fix the racks with metal corners with a reinforcing jumper.

- We lay the ridge girder edgewise on the support posts, check the horizontality and nail it.

- We nail a block to the base of the supports located in the middle, parallel to the ridge girder. It will serve as a bench, the installation of which would put too much strain on the frame building.

- We mount a strut, the top of which rests against the purlin, the bottom against the block at the base of the support. The angle of inclination of the braced part is about 45º. If several struts are to be installed, they are directed in opposite directions.

- We move the prepared rafters to the roof, put them in place, fasten them with nails at the top to the purlin, at the bottom to the trim and to the nearby ceiling beam. We start with the outer pairs, between which we should stretch the lace. Based on the readings of the laces, we install ordinary rafters.

- We dismantle the auxiliary block. We replace it with two posts nailed to the rafters at the top and to the trim at the bottom.

- We equip every second pair of rafters with a tie.

- To design the gable overhangs, we attach shortened cantilever beams with corners to the outer pairs of rafter legs, then we sheathe the perimeter with a wind board.

To make rafters, struts and beams we use 50×150mm, 50×200mm or 50×250mm boards. It should be taken into account that the cross-section of the material for the ridge run must be larger than the cross-section of the ordinary elements of the rafter system. The puffs can be made from 25x100mm boards.

The finished rafter system needs to be lathed: solid if it is planned to lay rolled material, sparse if it will be made of profiled steel sheet.

In the construction of layered rafter systems for small garages, the same technological principles are used. Regardless of the steepness of the slopes, an independent master will have to complete all the stages of work described above.

Rolled waterproofing is laid in strips over the finished rafter system, which is laid from the overhang to the ridge girder, then the sheathing and roofing.

Long-span pitched roof

An example of the construction of a roof over a long-span box confirms the unshakability of technological principles. The peculiarity of the structure is that the facility being developed is conditionally divided into sectors.

In addition to the load-bearing walls, there are two rows of support posts on which the side girders are laid. The purlin structure does not rest on the beams or floor beams, but on additional racks. The sectors of the box do not exceed the limit of 5 m, so they are not reinforced with rafter legs - struts.

Hanging roof schemes for garage

Hanging rafter systems are rightfully leading the way in the construction of small-sized garages. Owners and builders are not afraid of the complexity of repairing and replacing damaged parts of a hanging rafter system. It is much more convenient and safer to connect the rafter legs into trusses and then lift them onto the roof than to install each layered element separately at a height.

Elementary method of construction

Before erecting a roof using the hanging method, you should make an accurate calculation or stock up on a ready-made project with the exact dimensions of the gables.

We will construct a hanging rafter system for a garage roof as follows:

- We mark the future position of the rafter legs according to the project instructions.

- In accordance with the dimensions indicated in the project, we make trusses and file the lower grooves to support them on the frame.

- We first install the outer trusses adjacent to the gables and connect them together with a cord.

- We install intermediate trusses, not forgetting to check the lace readings. The upper edges of the rafters should form a flat imaginary plane.

- We install diagonal wind ties from inside the building. They will ensure the rigidity of the rafter frame.

- We cover the gables with OSB-3 slabs.

- We attach shortened beams to the ends of the outer trusses to form gable overhangs.

- We install a wind board around the perimeter.

- On top of the finished rafter structure we attach a sheathing, the type of which corresponds to the type of finishing coating and the requirements of the material manufacturer.

In the example, the lathing is arranged for a soft type of covering from OSB boards. A continuous roofing deck with similar characteristics can be made from boards. Those who want to find out how to properly sheath a gable roof on a garage should know that the slabs are laid staggered, and the boards are laid parallel to the overhangs or at an angle of 35º-45º to them. Between the elements of the sheathing, gaps of at least 3 mm should be left, necessary for thermal expansion of the materials.

A significant advantage of hanging structures is that the ties also work as ceiling beams. In the disassembled version, the screed is overestimated, and the internal lining is made directly along it. The attic is excluded in such a design solution. But thanks to the inflated screed, the ceiling and interior space increase, which can be seen in detail in the photo of the stages of installing a gable roof of a garage:

If hanging rafter triangles are to cover a span of more than 9 m, the tie is spliced from two boards or beams. At the top of the triangle, a suspension headstock is installed to prevent sagging of the tightening. It is connected by struts to the rafter legs. At the bottom of the suspension there is a device for tightening the tension in case of sagging.

Suspended structures for large spans

Hanging rafter systems are suitable for spanning spans up to 14 m. In private households, garages of similar dimensions are rare. However, large-sized buildings are often equipped with hanging roof trusses, as in the presented example of a two-story garage.

The walls of the two-story garage are made of timber, and the gables and internal partition are made of timber. Timber gables make it possible to abandon the truss scheme by installing slabs. However, the roof frame in the example is made traditionally: using hanging rafter triangles.

Rafter trusses are installed in the usual way: with the lower notches resting on the walls, with the tops facing each other. The junction of the tops is reinforced with wooden grooves. The ceiling of a cold roof is lined with plasterboard from the inside of the rafter system. Outside, a continuous waterproofing carpet is laid on the rafters.

The material is laid in strips with slight sagging in case of traditional wood movements due to moisture fluctuations with temperature. The waterproofing strips are laid in the direction from the overhang to the ridge; they are attached to the rafters first with a stapler, then with sheathing slats. A sparse sheathing is installed under the metal tiles and corrugated sheets at a pitch specified by the manufacturer. It is unacceptable to install bitumen waterproofing under metal coatings with a polymer shell.

In the case of constructing an insulated roof over a two-story garage according to the specified project, it is advisable to distribute the stages of work in a different way. The first step is to lay the waterproofing, mount the sheathing and secure the covering to it.

On large-area objects, it is more convenient and reasonable to install thermal insulation slabs or mats when the outer part of the roofing pie is completely ready. This eliminates the risk of the thermal insulation getting wet, which creates the threat of gradual destruction of the wooden elements of the rafter frame.

Video selection to help self-builders

The topic of the proposed video: construction of a garage and a gable roof for those who want to build with their own hands.

The basic options we have presented for constructing roofs with two slopes over garages demonstrate the basic principles of the structure. The proposed schemes are quite suitable for the construction of a free-standing box with a gable roof. Standard designs can be modified to suit individual requirements.

-

There are several design solutions for garage roofs. However, in order to minimize the necessary costs and get the most economical option, you need to choose the option of a pitched roof. Moreover, it can be attached to a residential building and provide direct access to the house.

The shed roof for the garage is widely used due to its simplicity, reliability and budget. The cost-effectiveness of this design is also ensured by its technological characteristics.

Construction of a pitched garage roof

A pitched roof consists of:

- the rafter system, which is the base on which all its components are attached and which absorbs the load on the roof;

- sheathing, constructed similarly to other types of roofs, which serves as a supporting surface for the roofing;

- insulating materials designed to retain heat and protect against moisture;

- roofing;

- additional elements that strengthen the rafter system.

A garage on which a pitched roof is installed must have logs or mauerlat (beams) at the upper ends. They will become the support for the future rafter system. As a rule, they are attached to walls using wire through anchors that are driven into the wall or placed specifically in the masonry.

Rafter system

The main element of the rafter system is the rafter (a wooden beam of a certain section). As is known, it can be

- suspended (supported by ends);

- layered (also has an intermediate load-bearing support).

If the span formed by the supporting walls is less than 4-5 m, as in the case of a garage, you can limit yourself to installing only horizontal elements (crossbars) on the rafter frame. At the junction of the mauerlat and rafters, sockets for fasteners are made. The rafters are installed in their position and securely secured with nails or anchors.

corrugated garage roof

How to make a pitched garage roof practically

Considering the size of the garage, a simplified rafter system with horizontal rafters can be made for it. Wooden beams can be laid along or across the garage. However, a transverse arrangement is considered more appropriate. This arrangement is more advantageous, if only because the timber along the width of the garage can have a shorter length.

Beams for an average garage (about 4 m wide) have a cross-section of 100x50 mm; for a larger garage width it is better to use 100x60 mm or more. The beams are laid in increments of no more than one meter.

After completing the installation, the wooden beams must be fixed with screws or angles to the walls of the garage or subsequently laid with bricks.

Lathing and insulation device

As soon as the work on installing and securely fixing the beams is completed, they begin laying the sheathing. Both edged and unedged boards (shalevka) can serve as the material for the sheathing. The latter option is considered optimal because it costs two times less than edged ones, and the final form is difficult to distinguish between them.

It is recommended to lay several edged boards, which usually come with shalevka, on the sides of the roof to eliminate gaps. If shalevka is used for flooring, it is cleared of bark. When laying and nailing, it is necessary to ensure that there are no large gaps. Compared to edged board flooring, of course, small gaps are possible, but this is not comparable to the difference in price of these materials. After insulation and filing, the gaps will become almost invisible.

On a note

It should be noted that not for every roofing material a pitched roof for a garage must necessarily have a continuous sheathing, however, a roof with a continuous deck is more reliable

The next stage is the installation of waterproofing, which should protect the interior of the garage from penetrating water. For these purposes, various materials are used, for example, roofing felt or special roofing films (hydrobarrier, eurobarrier).

The most budget option remains roofing felt. It is laid from the bottom up so that a small overlap of a couple of centimeters is formed. In this case, water that gets from under the roofing material will roll off without getting under the bottom, that is, the boards.

The roofing film is laid in the same way, secured with stainless nails or staples. Ruberoid is simply nailed down.

Laying roofing on a garage roof

Next, the garage roof is laid on a wooden deck. The choice of roofing materials for a pitched garage roof is quite large, and each material has its own individual characteristics and advantages.

- – is resistant to precipitation, it can be reused, although it is already relatively inexpensive.

- Slate looks good, is easy to install, service life is 30-40 years, but is not always justified for small garages.

- Seam roofing - strips of thin sheet metal are easy to install and reliable, but this option is not cheap.

- Roof tiles or metal tiles - more suitable for covering capital stone garages of large and medium size

- (rubemast, roofing felt, roofing felt, etc.) - are inexpensive, easy and quick to install and, most importantly, durable and effectively protect the room. If roofing felt can last up to 10-15 years, then its modern analogs can last up to 30-40 years on average.

Capital or frame technology for constructing a garage

Of the popular technologies existing today, two can be distinguished: capital and frame. Unlike the first, which requires a variety of building materials and equipment, the frame is based on technical components manufactured in the factory - it is only necessary to carry out final assembly.

A frame garage with a pitched roof has some advantages:

- excellent thermal insulation,

- fast construction,

- cheap solution.

In addition, a frame garage does not require a massive foundation due to its lightweight walls.

In everyday vocabulary words "roof", "coating" And "roof" act as synonyms. However, in architecture and construction these meanings are distinguished by considering the roof to be the upper structure that protects the building from weather phenomena such as rain, snow, and strong wind.

The roof underneath is made up of a number of required elements, presented depending on its kind, in full or in part:

- rafters;

- rafter beams;

- slopes (valleys);

- ribs;

- skate;

- outer covering.

The outer covering, in essence, is roof, because it covers the roof slopes with waterproof material, forming a protective deck.

Interesting: In sunny Egypt, where there is no need to protect the building from precipitation, roofs are not erected quite deliberately: without a roof, a house is considered unfinished and is not subject to property taxes.

Garage - photo of the roof:

As you can see in the photo, the garage roof should be durable And sustainable. We'll talk about this below.

Kinds

According to their design features, there are several types of roofs. First of all, by the presence of stingrays:

- flat;

- pitched.

Flat roofs for a garage they require a continuous elastic “carpet” made of bitumen-polymer materials that is tolerant of temperature changes. The support for such a roof is the walls of the building, and the base is slabs or. Solariums and hanging gardens are sometimes installed on a flat roof. In this case, the roof is considered exploited.

Pitched roofs are formed by slopes at an angle from 10⁰ to 60⁰, resting on the rafter system, and are:

This could be a workshop, storage room, office or guest room. It is distinguished from an attic by the height of the covering: not less than 1.5 meters. This is a rather expensive roof project that will require heat, hydro and vapor barrier, non-standard double-glazed windows for windows, and a sharp bend in the rafter pair, which reduces the strength of the structure.

Only pitched roofs exist 8 types, and each of them has its own modifications depending on the angle of slope and the size of the overhangs. The most popular ones for the garage are: single-slope And gable.

Garage roof

Taking into account the force and atmospheric effects on the roof, its coating must meet the following requirements:

- strength;

- sustainability;

- tightness;

- resistance to moisture, cracking, deformation due to changes in t⁰;

- UV resistance;

- penetration protection.

These conditions are met by a number of roofs common in domestic construction:

- (rolled - roofing felt, mastic);

- sheet (corrugated asbestos cement, steel, copper, corrugated sheets, metal tiles, ondulin);

- small-piece materials (asbestos-cement tiles, tiles, shingles).

The main criteria for choosing roofing material are:

- roof design features;

- own weight of roofing material;

- climatic operating conditions;

- location of the garage (relative to housing);

- resistance to aggressive influences;

- terms of expected operation;

- compliance with the building style;

- value for money.

Reference: Ideal material for roofing No. Giving preference to some of its qualities, you need to be ready to sacrifice others that are less significant for a particular building.

Types of garage roofs - photos:

Material characteristics

- polycarbonate slate - colored translucent sheets;

- fiber cement - without the use of asbestos (cellulose filler);

- keramoplast - modification of slate made of composite materials;

- roofing profiled sheet obtained by cold rolling.

Natural slate has many advantages:

- resistance to external influences (temperature, chemical, biological);

- durability (up to 40 years) and low thermal conductivity;

- economical and easy to install;

- used when slopes are inclined 25-35⁰.

Disadvantages are worth special attention:

- fragility;

- moisture saturation;

- unsafe for human health.

Requires a protective coating with acrylic paint with an anti-corrosion composition. For metal roof There are standard additional elements on sale: cornices, gutters, gable overhangs, ridge corner, drainpipes.

Leakage: causes and elimination

The main trouble that a garage roof can cause is leak. There may be several reasons:

- exposure to abnormal natural phenomena;

- during the period of operation, the strength resource is completely used up;

- there were defects during the installation of the roof;

- neglect of the stage in the construction of the roof affected;

- inconsistency between the installation technology and the roofing material used;

- low-quality covering material;

- mechanical damage when clearing the roof of snow and ice.

Leakage It is important to identify wet spots and mold as soon as they appear, without waiting for jet streams. First of all, the places of joints and connections are checked, then - damage to the integrity of the roof (cracks, chips, holes). Remove blockages from fallen leaves in the corners of the valley, which can accumulate moisture.

It will depend on the characteristics of the roofing material and the amount of damage. Soft and small-piece materials are easier to fragmentary repairs. The scope of repairs to sheet and panel coverings will depend on the complexity of the damage.

Important: When preparing a drawing of a garage roof and designing, it is necessary to include additional building materials in the purchase 10% (in excess of the estimated amount) for unforeseen expenses. These are the ones who will help you out in case of a leak.

Many people say that they will need to call specialists to install a garage roof. Yes, this is a critical stage of work that requires some skills and basic knowledge. But, if you know how to hold a hammer in your hands and consider yourself capable of doing this work, then building a garage roof with your own hands is a very realistic goal. You only need to study the intricacies of the work and installation instructions.

If you have all the tools and materials, the job will go quickly and you will be able to cover your garage well. And we will help you with that. This article will introduce you to the technology of installing a gable roof on a garage.

What are the advantages of a gable roof

To begin with, I would like to note that a garage is not a house. There is no need for complex shapes, elegant designs, etc. It is a purely functional building. And the simpler it is to make, the better. The simplest option is a pitched roof. But we will consider a gable roof. This is a simple design that consists of two inclined planes. The planes are called roof slopes. The slopes rest on the building box and converge at one point at the top. It's called a skate. If you look at it from a distance, the gable roof resembles an isosceles triangle. Why did we decide to cover our garage in this particular way? There are several reasons for this:

By installing a gable roof on your garage, you get a lot of benefits. It's profitable and easy.

Note! Such a building will look like a separate structure, which cannot be said about lean-to structures. It can be placed not only near the house, but also in another convenient place on the site. According to many professionals, the recommended roof slope is 20-30˚. And you can choose a roofing material identical to what you have on your house. So, everything will look harmonious.

Creating a roof project for a garage

Before making a gable roof, you need to think through everything in advance. What does this include? It is important to know the following parameters:

- ridge height;

- quantity of consumables;

- type of roofing;

- slope of the roof slopes.

In addition, after constructing the roof, you need to think about making a drain yourself. It will effectively handle rainwater, diverting it away from the building. Otherwise, your efforts may come to nothing in a few years.

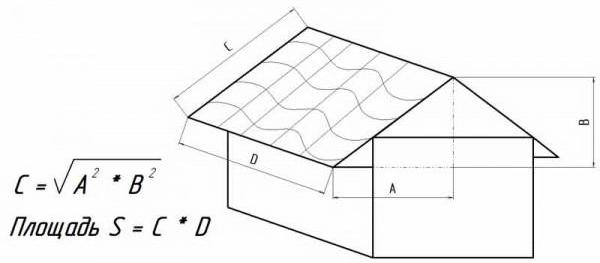

When performing structural calculations, the loads that will be exerted on the frame elements are taken into account. You need to calculate the weight of the roof to understand how deep the foundation should be. To create a working diagram, correctly perform the following calculations:

Roof frame made from rafters

The basis of any gable roof is the rafter structure. This is a complex of elements that ensure the stability, strength and stability of the roof. The frame is made of wooden rafters. It is better if it is coniferous wood. And in order to extend their service life, before work they are coated with an antiseptic and fire-resistant compound.

Depending on the layout of the building, weight and area, there are two types of rafter systems:

Do-it-yourself gable roof for a garage

Now comes the most difficult stage of work. All this needs to be put into practice. It will be good if you make a schematic drawing in advance, which will indicate all the dimensions of each of the frame elements, the required distance, and the method of fixation. After this you can start working.

The execution process is as follows:

Note! In the gables you can make windows for natural light and ventilation, as well as doors through which you will enter the attic. Your garage roof is now ready. After reading this information, everything may seem complicated to you. But this is only at first glance. Once you start the process, things will work out. And to make your task easier, we suggest you additionally watch a video on how to make a roof for a garage.

Choosing roofing material for a garage

Many people often wonder how to cover the roof of a garage, because there are many materials for this purpose. Based on the climate in your region, your financial capabilities and the durability of the material. Rolled products are not entirely suitable, since their service life is short. They are most often used for these purposes.

For the garage, it has gained popularity among car owners due to its simplicity and efficiency. Creating a pitched roof requires modest skills and inexpensive materials. But at the same time, the design will be durable and will reliably serve you for a long time.

Another great advantage is the short installation time. All this makes the single-pitch the optimal solution for.

How to do garage roof with your own hands? The most important thing in the device pitched roof The garage will have a rafter system with its own hands. It receives and distributes most of the weight, transfers it to Mauerlat.

Lathing is no less important. The battens will serve as support for the roofing fastenings. The final element is the outer layer, itself roof covering. In addition, we must not forget about waterproofing and thermal insulation.

Shed garage roof - photo:

For garage with flat roof Manufacturers offer a wide range of roofing materials:

- Slate– has a good appearance and is relatively easy to install. Service life is 35-40 years;

- Roof tiles– best suited for creating roofs on medium/large garages;

- Corrugated sheet– low price, fairly reliable option;

- Soft materials– rolled building materials are low cost. The service life of modern materials is 30-40 years. Roofing felt is much shorter – 10-15 years.

The angle of a flat roof for a garage depends on several factors. First - material type. Roofing felt has the lowest angle of inclination - 5-10 degrees. Slate and tiles have more - 20 and 30 degrees, respectively.

The second factor is climate. To determine the required angle of inclination, you need to know the average wind force and the amount of precipitation. For example, if the garage will be exposed to strong winds, the roof should be made with a smaller angle, more flat.

Please note that the angle and strength of the structure are in inverse relationship. It will be necessary to compensate for the loss of strength with special supports and other structural solutions.

How to make a garage roof? We need to start with calculation. In practical terms, the angle of inclination will show the difference in the height of the walls. That is, how much higher one wall of the building is than the other. For a regular, single garage, a difference of 40-60 centimeters is suitable. The roof will be strong and reliable. To make calculations, trigonometric equations are used.

Height difference:

РВ = ДС x tgA, Where

RV– Height difference;

DS– responsible for the length of the garage wall;

tan A– tangent of angle A, angle A is the angle of inclination of the roof that you have outlined for yourself.

Rafter leg:

CH = РВ x sin A, Where

CH– rafter leg size;

sin A– sine of the roof inclination angle;

RV– height difference, it is obtained from the previous formula.

For calculations, you can use special programs and calculators; it is not necessary to do everything manually.

DIY frame garage with pitched roof- photo:

Installation

Do-it-yourself pitched roof for a garage - step by step:

Slate

How to make a roof for a garage? Styling slate you need to start from the bottom. The material is laid in rows, the top sheets are placed on the bottom sheets, and partially cover them. If four slate sheets intersect in one place, special nails are used for fastening. At the edge of the roof, the roofing material is nailed down with a pair of nails.

To reduce the influence of wind, use wind board. It is laid on the rafters; the board will provide some protection from strong gusts of wind. The advantage of slate is its low price and durability (30-40 years). The tilt angle is 20 degrees.

Corrugated sheet

How to make a pitched garage roof? By using corrugated sheets- inexpensive roofing material. The tilt angle is 20-40 degrees. But an angle greater than 25-30 degrees must be chosen reasonably, as the strength of the structure will suffer. The basis for such a decision may be heavy precipitation (especially snow) in your region.

Laying the material begins with bottom corner. We must not forget about leveling the corrugated board; the cornice strip will serve as a guide for this.

It is necessary to strictly adhere to the selected overlap size. The size directly depends on the angle of the roof. The larger the angle, the less overlap will be needed.

When roofing the roof of an attached garage, sheets of corrugated sheets fastened with self-tapping screws. Particular attention should be paid to the end of the structure. In this section, self-tapping screws are attached to all beams. Do not skimp on self-tapping screws, use a standard quantity, otherwise you will suffer reliability roofs.

For installation you will need a simple tool - a power saw, electric drill, screwdriver.

Do-it-yourself garage with a pitched roof:

Soft roof

This includes many building materials. Soft materials are not laid at a large angle, maximum 10-15 degrees. The cheapest and most common is roofing felt.

How to properly install a roof on a garage? To begin installation, you need to prepare the roof, clean its surface of debris, and let it dry thoroughly. You need to prepare yourself roofing felt– a couple of days before the start of work, they open it and let it rest. Then a primer is applied to the roof, which will remove cracks and gaps.

After this, they apply to the rolls mastic(cold or hot). Rolls of roofing felt should be laid overlapping, in layers. The top layer must have a protective coating. The protruding edges are folded in and secured with nails.

Modern roll materials have an increased service life and improved characteristics, but the installation process is generally similar to roofing felt.

DIY garage roof - photo:

Conclusion

How to build a roof on a garage? The first step in building a pitched roof is to create Mauerlat. Mauerlat distributes the weight from the roof to the walls of the garage. Then they move on to the rafter system.

The protrusion of the beams should be approx. 30-40 centimeters. The ends will protect the garage from precipitation entering the interior. The laying step is 70-80 centimeters. The next stage will be sheathing.

Lathing for soft, rolled materials should be solid. This is not necessary for slate and corrugated sheets. The sheathing is attached perpendicular to the rafters. After this you need to do waterproofing battens.

Good for waterproofing roofing felt. It's cheap and easy to install. Instead of roofing felt, you can use film; it is laid in the same way. Then the outer layer of the roof is laid.

Useful video

Watch a video on how to properly make a pitched roof on a garage with your own hands:

Another educational video on how to make a roof on a garage - a pitched roof: