The triangle has great stability compared to other simple shapes. It underlies various rafter systems. If you are faced with choosing a shape, type of roof and roofing material, then a do-it-yourself gable roof for a garage would be a reliable option.

Why gable?

It will be easier to answer this question if you just know all the benefits:

- Great convenience and ease of installation. Having good instructions, even someone who does not have much experience in roofing can handle the construction of such a structure.

- Availability of components. All necessary elements can be purchased or ordered specifically for your project.

- Possibility to choose the best slope angle. This ensures good removal of precipitation, which means a long service life of the coating and other materials.

- If no roof space is planned, a cold attic will reduce the need for additional heating and ventilation.

- Convenient placement of various components in the under-roof space.

- The advantage of organizing an attic space.

- Choice of any type of roofing.

- Installing additional windows or skylights.

- Possibility of an individual approach.

Sometimes the implementation of the shape of a gable roof can be very interesting. It doesn't have to be an isosceles triangle shape. Also distinguished:

- Asymmetrical. In this case, the length of one slope may exceed the other. This option can be used in cases where the house is located at a significant difference in ground level. Or there is a high-height extension on one side.

- Hip or hipped. This option is more like a pyramid, so it is more stable. Also its appearance is more attractive.

- Half-hip. In this option, two parallel slopes are not lowered to the very end. The gables can have windows, as well as a manhole.

- Broken or attic. This option is perfect if you are planning to make an additional room in the attic space.

The slopes do not have to be absolutely smooth. They can be made in the Chinese style - with a recess, or, conversely, in the shape of an arch. Everything will be limited by the imagination of the customer and the capabilities of the contractor.

Basic Concepts

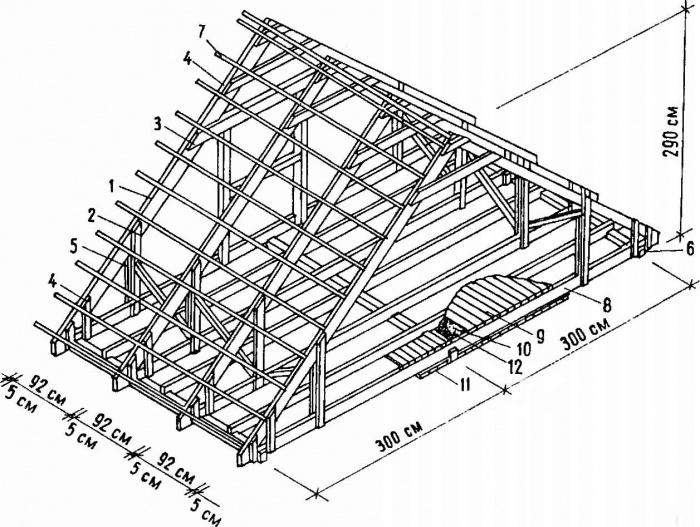

Before starting any work, you need to familiarize yourself with the theory. The main components of the rafter system are:

- Mauerlat. This is the foundation of the entire structure. It is usually made of timber or several boards that are fastened together to form a monolithic rectangle.

- Rafters or rafter legs. These are inclined beams (sides of the triangle) that run along the entire perimeter and are responsible for the rigidity of the entire structure.

- Struts. These are also beams that are installed at a certain angle. Their purpose is to create support for the rafter legs.

- Bolt or tightening. The cross bar, which is the base of the triangle. It can be raised or located between the edges of the rafter legs. Sometimes two of them can be used in a design.

- Grandma. This is the vertical bar (the height of the triangle). It is attached between the rafter legs. Used in cases where the roof width exceeds 6 m.

- Run. An additional beam that is laid parallel to the mauerlat. It is supporting and is used in cases where it is necessary to mount the headstock.

- Filly. It is used in cases where the slope does not protrude to the required level. Attached as a continuation of the rafter legs. Usually made from smaller boards.

- Horse. The junction of the two crossbar legs at the apex.

- Ridge run. A longitudinal beam, which is located at the bottom of the ridge or serves to connect the legs.

- Rack. A board that is installed parallel to the headstock, but closer to the corner. Serves to evenly distribute the load and transfer it to the internal walls.

- Lathing. Slats that are attached along the outside of the entire roof plane. Necessary in order to ensure good fixation of the future roofing.

It is important to remember that some of these elements will not be necessary for all projects. They are needed in order to increase rigidity and stability when the width of the supporting walls exceeds 6 m. Also, with this width, hanging rafters are usually chosen; if the width is larger, then supporting ones will be needed.

Note! During the installation process, sometimes it becomes necessary to increase the length of the rafter legs or other elements. To do this correctly, you need to join two boards and grab them with pieces on both sides of the seam.

Any construction project begins not with the application of force, but with the use of mental abilities. First - numbers, then - how to do it. The calculation of the roof begins with choosing the angle of inclination of the slopes. This will depend on:

- amount of precipitation;

- location of the building;

- selection of flooring material;

- maximum wind force;

- desire to install zeniths or windows;

- budget - the larger the slope angle, the more expensive it will cost. Indeed, in this case, more material for flooring will be needed.

The more precipitation there is throughout the year, the greater the angle must be so that water or snow can be easily removed. This is important so that the critical load does not increase and moisture stagnation does not occur. If strong winds are often observed, then the angle will need to be reduced. If it is planned to have skylights, then the angle should not exceed 25˚. Usually the most optimal values are considered to be 20–35˚ (sometimes the slope can reach 45˚).

Note! The degree of load from blowing winds is taken from the average readings for the region and multiplied by a correction factor. The snow cover value is also taken from the average and multiplied by a correction factor (usually this figure is in the range of 80–320 kg/m2).

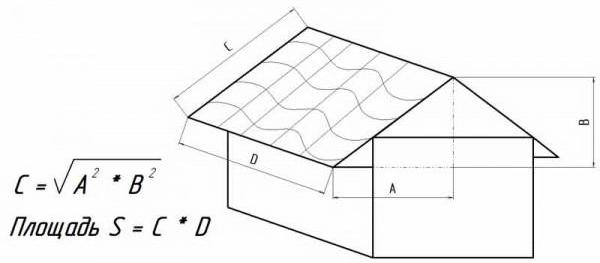

When the angle is determined, you can set the height of the future structure. To do this, you need to use basic concepts from geometry. You need to divide an isosceles triangle into two right triangles. This way we will know the length of the base; it will be equal to half the width of the building. Now, having this value, it must be multiplied by the tangent of the selected angle (the tangent value can be viewed from the Bradis tables). When we know the length of two legs, we can find out the length of the future slope. To do this, we square the length of each, and then add the result. After this, it must be removed from under the root. But remember that the slope will need to be slightly increased in order for the formwork to be covered.

Note! The pitch between the rafter legs is selected individually depending on the loads. Usually it is in the range of 60–120 cm.

A gable roof is essentially two rectangles that rest on one another, so it’s easy to calculate the area. To do this, we multiply the length of the slope by the total length of the roof and multiply the resulting result by two more.

Having all the values, you can calculate the material that will be required. The amount of roofing material will be equal to the area of the slopes. For the Mauerlat you will need a beam of 15×15 or 10×10 cm. The total length will be equal to two lengths of the building. For crossbar legs, a 15x10 cm board is usually used (it is also used for headstocks and jibs). To find out how many will be needed, you need to determine at what distance they will be located. This will give the quantity in pieces. Knowing the quantity and dimensions, you can calculate the number of m3. It is also necessary to consider what additional elements will be used. For the purlin, you can use 15x10 cm timber. For the sheathing, the material is selected in accordance with the recommendations of the flooring manufacturer.

Note! Online calculators are now available to automate the calculation of all values.

Installation

Before starting installation, you must make sure that the load-bearing walls are strong enough to withstand not only the weight of the roof, but also the weight of maximum precipitation. The ideal option would be to have a reinforced belt at the top.

- The first thing to do is to ensure waterproofing of the Mauerlat. To do this, roofing material or other similar material is laid along the entire plane of the upper end of the wall. Wood absorbs moisture well, which can easily rise through the macropores of concrete. If this is not prevented, the beams will simply rot.

- The beams are cut to the required size and lifted onto the wall. They are attached to the concrete using bolted (pressure) anchor bolts. Under no circumstances should frame ones be used. They serve as spacers. Another method is studs. But they will need to be walled up at the stage of building the wall or pouring the armored belt. Their depth should be about 1 m. The Mauerlat is located either closer to the inner edge or in the middle. The distance from the outer edge should not be less than 5 cm.

- In addition to timber for the mauerlat, you can use several boards. In this case, they will need to be tightly tightened together using screws or nails. If you have to make it from non-solid timber, then the dressing should be in the middle of the wall and not move towards the edges.

- Next, you can proceed to the installation of the transverse beams. The design may be different: several longitudinal purlins are mounted, and ceiling boards are already hemmed to them.

- Now you need to set guidelines in order to install the trusses. To do this, you need to mark the installation locations of future rafters on the Mauerlat. We already know their number and step. First, the extreme points from the walls along the edges of the support beam are measured. After this, be sure to check the diagonals to ensure there is no misalignment.

- Trusses can be assembled directly above, or ready-made structures can be raised onto the garage.

- Most builders pull several guide ropes to maintain one plane. One goes along the ridge and two more at a distance of about 50 cm. But this approach is not always rational. The wind may move the level of the thread, or it may be lifted by a board. To prevent this from happening, you can do the following. Several vertical supports are installed and secured with jibs. A longitudinal board is attached to these supports. It will serve as a level. Its rigidity is enough to correctly set the angle and general plane. After installation it can be dismantled. True, this method will be irrelevant if the farms are assembled below.

- There is another option. Two outer trusses are installed, and a ridge support or several longitudinal boards are thrown between them. They will serve as a level.

- If you don’t want to bother with adjustments so that the tops of the trusses are butted, then you can make them overlap. Installation begins with the gable rafter legs (they must be butt-joined to facilitate future cladding), from one and the other edge. You need to move towards the middle. The legs are connected to each other using nails or a bolt. A wooden plate must be thrown from below; it can be replaced with a nailed metal plate.

- Along the way, temporary jumpers are installed that hold the entire structure.

- In places where the rafter will be adjacent to the mauerlat, it is necessary to make a gash so that the leg fits well. Fixation occurs using a sliding support or a metal corner.

- It is important to ensure that the difference in height of the rafter beams does not exceed 1 cm, otherwise the roof will not be level.

- After all the rafter legs are installed, you can proceed to the installation of the vapor barrier. It is attached using a construction stapler to the crossbar legs according to the marks applied to the film.

Many people say that they will need to call specialists to install a garage roof. Yes, this is a critical stage of work that requires some skills and basic knowledge. But, if you know how to hold a hammer in your hands and consider yourself capable of doing this work, then building a garage roof with your own hands is a very realistic goal. You only need to study the intricacies of the work and installation instructions.

If you have all the tools and materials, the job will go quickly and you will be able to cover your garage well. And we will help you with that. This article will introduce you to the technology of installing a gable roof on a garage.

What are the advantages of a gable roof

To begin with, I would like to note that a garage is not a house. There is no need for complex shapes, elegant designs, etc. It is a purely functional building. And the simpler it is to make, the better. The simplest option is a pitched roof. But we will consider a gable roof. This is a simple design that consists of two inclined planes. The planes are called roof slopes. The slopes rest on the building box and converge at one point at the top. It's called a skate. If you look at it from a distance, the gable roof resembles an isosceles triangle. Why did we decide to cover our garage in this particular way? There are several reasons for this:

By installing a gable roof on your garage, you get a lot of benefits. It's profitable and easy.

Note! Such a building will look like a separate structure, which cannot be said about lean-to structures. It can be placed not only near the house, but also in another convenient place on the site. According to many professionals, the recommended roof slope is 20-30˚. And you can choose a roofing material identical to what you have on your house. So, everything will look harmonious.

Creating a roof project for a garage

Before making a gable roof, you need to think through everything in advance. What does this include? It is important to know the following parameters:

- ridge height;

- quantity of consumables;

- type of roofing;

- slope of the roof slopes.

In addition, after constructing the roof, you need to think about making a drain yourself. It will effectively handle rainwater, diverting it away from the building. Otherwise, your efforts may come to nothing in a few years.

When performing structural calculations, the loads that will be exerted on the frame elements are taken into account. You need to calculate the weight of the roof to understand how deep the foundation should be. To create a working diagram, correctly perform the following calculations:

Roof frame made from rafters

The basis of any gable roof is the rafter structure. This is a complex of elements that ensure the stability, strength and stability of the roof. The frame is made of wooden rafters. It is better if it is coniferous wood. And in order to extend their service life, before work they are coated with an antiseptic and fire-resistant compound.

Depending on the layout of the building, weight and area, there are two types of rafter systems:

Do-it-yourself gable roof for a garage

Now comes the most difficult stage of work. All this needs to be put into practice. It will be good if you make a schematic drawing in advance, which will indicate all the dimensions of each of the frame elements, the required distance, and the method of fixation. After this you can start working.

The execution process is as follows:

Note! In the gables you can make windows for natural light and ventilation, as well as doors through which you will enter the attic. Your garage roof is now ready. After reading this information, everything may seem complicated to you. But this is only at first glance. Once you start the process, things will work out. And to make your task easier, we suggest you additionally watch a video on how to make a roof for a garage.

Choosing roofing material for a garage

Many people often wonder how to cover the roof of a garage, because there are many materials for this purpose. Based on the climate in your region, your financial capabilities and the durability of the material. Rolled products are not entirely suitable, since their service life is short. They are most often used for these purposes.

Garage roof structures come in several types. In order to choose the best one, you need to familiarize yourself with the specific features of each of them. So, different options are mounted differently.

Peculiarities

A roof for a garage is different in many ways from a roof for a house. This is due not only to the fact that the garage is used as an additional utility structure, but also to the fact that there is no need for such high-quality thermal insulation. Therefore, roofs are covered with inexpensive materials that do not cause difficulties during their installation.

A specific feature of the garage roof is that its shape and design are selected relative to the location of the garage house. In addition, it is determined by the stylistic coloring of the facade of the main house, as well as the surrounding landscape. However, it must be remembered that there should not be any special frills here, because the garage is still not the main structure, and in theory it should not attract too much attention to itself.

Due to the simplicity of the design, garage roofs will not cost much. This is due to the low cost of materials and repair work. Due to the ease of installation, construction work will cost little. Thanks to this same feature, installation can be done independently, without the involvement of specialists.

photos

Such high-quality insulation is not required, so this side detail can be easily dispensed with.

Kinds

This is not to say that garage roofing comes in a wide variety of types. Simplicity and functionality are the fundamental principles in accordance with which the choice is made in favor of one design or another. This is the reason for such a meager choice.

The choice in favor of one type or another is made based on several factors. Firstly, the climate zone in which the garage is built is important. How windy the area is and how much rainfall there is directly affects the choice of design and roof slope. Secondly, again, overall harmony is important. It is much better if the garage roof is similar to the one on the house. Thirdly, the chosen material plays a role. Some types look good only on roofs with one slope, others - with two.

Before choosing one type or another, it is necessary to analyze the situation with the construction of a garage. First of all, you need to know:

- the climate in which the garage building will be located;

- whether the garage will be adjacent to the house or separate;

- what material is the roof made of?

- height of the roof above ground level.

By answering each of the questions posed, you will be able to choose the best option that is suitable for your particular case.

Each type of roof has its own subtypes, which are also worth keeping in mind. The use of one or another subtype is determined depending on the area of the roofing. Thus, it is possible to prevent the roof from collapsing, its subsidence under the weight of precipitation, and the load on the foundation is also regulated.

Flat

A roof with a slope height of up to 3 degrees is classified as flat. Compared to pitched roofs, it has a number of advantages:

- a flat roof takes up much less space than a pitched roof, resulting in savings on materials for its manufacture;

- a flat roof can be built much faster than a pitched roof, since complex calculations regarding the rafter system are not required;

- repairing a flat structure is much easier and safer due to the fact that the risk of falling by sliding down a surface with a steep slope is reduced;

- if the garage is attached to the house, then such a roof can be converted into a balcony or used as a terrace on the second floor.

However, flat roofs are not suitable for areas with strong winds and heavy rainfall, as they may fail and collapse under the weight of the snow. This also explains the fact that such a roof will have to be periodically cleared of snow and icy crust.

photos

To drain water from such roofs, it is often necessary to organize additional drainage channels. The tightness of the roof is under threat: this must be constantly monitored, carrying out preventive maintenance every year.

Low slope

Low-slope pitched roofs are considered a universal solution. They are suitable for areas with an average climate. The garage may not be located in the city, but it should not be located in a windy steppe space. The slope angle of low-slope structures varies from 3 to 30 degrees. The advantages of such roofs are some features that will be discussed below. A special feature is that the slope for each specific case is determined through calculations, and the minimum acceptable value is selected. Calculations are made based on the roofing material.

When building low-slope roofs, several specific features will need to be taken into account:

- The need to equip a drainage system of internal or external type.

- The roof must have good tightness.

- The need for a ventilation gap under the roof. Its size is determined according to the angle of inclination: the flatter the roof, the larger the gap.

Thus, choosing a low-slope roof guarantees savings on materials, but you will have to spend a lot more effort and money on the structure itself. Make sure that the choice of a low slope is justified in terms of aesthetic appeal.

Steeply inclined

The angle of inclination of steeply pitched roofs starts at 30 degrees. As with other options, this variety has both pros and cons. It is necessary to use roofs with a steep slope if the garage is located on windless areas (for example, in urban areas). If there is a lot of snow in the area, then such a roof will allow you not to waste time on cleaning it, because the snow will not linger on it, rolling down steep surfaces.

This option is completely unacceptable for windy areas. Thus, the roof can easily be blown away by a strong gust of wind. If the area is windless and there is little precipitation, then the costs of such construction will not be justified.

Thus, the choice of one or another variety is primarily determined by the location of the garage and the site as a whole.

For steppe windy deserts, it is best to choose flat or low-slope roofs; for wooded areas, low-slope options are best suited; and for urban areas with large amounts of precipitation, a steeply sloped variety is the best choice.

However, roofs are divided not only by angle of inclination. There is another classification of roofs - by the number of slopes. For garages, only two types are used: single-slope and double-slope.

Single-pitch

Shed roofing is valued for its simplicity and functionality.

- Firstly, its installation actually takes less time than the construction of a gable version.

- Secondly, it will not be difficult to make all the calculations for the required amount of material. This step can be taken independently, and the accuracy of the calculations will not be in doubt.

- Thirdly, such a roof requires significantly less material than a gable structure of the same area.

- Fourthly, a pitched roof is an excellent option if you need to design a garage attached to the house. She looks the most harmonious.

- Fifthly, it is believed that pitched roofs are more durable than gable roofs. In addition, they are more reliable and stronger, and thanks to timely repairs they can last up to 50 years.

Mono-slope structures are not without their disadvantages.

- Due to the fact that in most cases, single-pitch options are flat, the load on them increases in winter. Snow doesn’t roll off on its own, and you have to either clear it off yourself or trust that the roof will bear it.

- With the lean-to option, you will definitely have to abandon the attic, even if a small attic space was initially planned.

- This variety is more difficult to equip with decent thermal insulation.

- Many people notice that the single-pitch structure looks rustic compared to the expressive gable one, and in some cases this causes certain inconvenience to the owners.

Gable

A gable roof is more often used for detached garages. Seeing it on a structure attached to a house is very rare. Nevertheless, gable options have their advantages.

- Thanks to its special shape, such a roof does not retain snow and rain. They roll down instead of weighing down the structure.

- Although a gable roof is more complex than a single-pitch roof, you can make a garage version yourself if you take into account some adjustments.

- By choosing the basic option, you can save a lot on work, since you will be able to complete it alone, or at most with a partner.

- The gable design allows it to be equipped with good thermal insulation, thereby reducing heat loss. So, when planning a warm garage, other roofing options cannot be considered.

- The gable roof allows you to organize a small attic where you can store tools and other equipment. In cases where a hinged gable structure is chosen, it is possible to increase the ceiling height.

Having assessed exactly how you want your garage to look in the end, you can easily choose the type of roof structure for it.

Materials

Roofing materials are not only those on the outside. For internal construction, their own types are also used. If the rafters can be made from wooden beams, then several materials are suitable for waterproofing. Most often, roll insulators are used for this, for example, bikrost, roofing felt, roofing felt. Instead, you can use bitumen mastic, which will reliably protect the roof from water penetration.

But it is also important not to buy too expensive materials for covering the garage roof. For example, a garage roof lined with ceramic tiles will look strange and out of place. If the roof of the main house is finished with such an elite material, it would still be better to choose a cheap equivalent for the garage. This will show both the good taste of the owner and his practicality, allowing for significant savings.

For an internal wooden structure there is also an analogue - a concrete frame. It should be kept in mind that Concrete is much heavier than wood, the load on the foundation of the building will increase significantly. In this regard, before choosing such an alternative, it is necessary to ensure that the strength of the structure is sufficient.

Corrugated sheet

One of the most common materials used to cover a garage roof is corrugated sheeting. This type is so often used due to a number of advantages, including a large selection of colors, price, and ease of installation. In addition, the corrugated sheet is durable. If you lay it properly, a durable, aesthetically attractive coating will be guaranteed.

Corrugated roofing differs in the height of the corrugation, the width of the sheets themselves and the type of galvanized steel used in production. The material of the NS category belongs to the roofing class, so when choosing, you should definitely look for this particular marking. Please also pay attention to the presence of the GOST mark. If it is not there, this means that during production other standards were taken as a model or there were no standards at all. From this we can conclude that corrugated sheeting without such a symbol is not always of high quality.

For roofing, it is necessary to choose profiled sheets with a polymer coating. Polyvinyl dichloride, pural and polyester are considered suitable. The first is the most durable sample, but its cost is slightly higher, but the other options are cheaper, but less wear-resistant.

Slate

Dull gray slate material has long become a classic of the genre, and when it comes to slate, everyone imagines just such roofs. Despite its unattractive appearance, slate has excellent strength characteristics. If you choose a high-quality sample made in accordance with modern technologies, it can easily last up to 50 years.

- Slate is made from different types of raw materials. Plastic, asbestos-cement, soft, rubber and metal are used. Each of these subcategories has its own characteristics and advantages.

- For example, the asbestos-containing option has excellent technical performance and low cost, but asbestos is toxic, and this type of slate is harmful to health.

- Soft slate does not have frost resistance, but it is strong, durable and at the same time flexible.

- Plastic slate lasts up to 15 years without loss of strength, but it must be installed carefully, given that it tends to either shrink or expand depending on temperature changes.

Nowadays there is a wide variety of decorative solutions on the market, and you can choose slate material of any color.

"Ondulin"

The company name Ondulin has long become a household name, which is used to designate roofing sheets that imitate other materials. There are three types of them that are most popular.

- Smart. The material has a small mass, as a result of which it is possible to carry out installation alone, without the help of a partner. Thanks to the optimal size of the sheets and their small thickness of only 3 mm, you can completely sheathe the roof of the garage in one day. It will take a lot of nails. And also when working with Smart material, the joints will need to be covered with additional decorative elements.

- Diy. This variety is more rigid than the previous one. This is due to the fact that the waves here are more frequent and higher. The mass of the material remains the same. Thus, such options are more suitable for roofs of complex architecture, rather than for elementary garage structures. The material is laid overlapping, due to which its consumption increases.

- "Tile". Finishing with this type of sheet is indistinguishable from finishing with metal tiles, but it is much easier to implement than laying a real tile roof. There is a wide variety of color options, and there are not only plain roofs, but also spotted ones.

fold

Steel roofs raise more questions than all others.

- Firstly, they are not strong enough. Any severe mechanical damage will easily warp the overly flexible material.

- Secondly, steel does not hold temperature at all, as a result of which it will be necessary to take additional care of the heat-insulating layer.

- Thirdly, the waterproofing is also not at the proper level: the roof can easily begin to leak, jeopardizing the safety of your car. The roof will need to be additionally sealed.

However, seam steel floors have several significant advantages. In the first place is the price: it is an order of magnitude lower than the cost of other options. Repairing this roof is also easy, since the panels are fastened to each other using ordinary tucks. The roof can be covered with this material even in winter. Due to its flexibility, steel is ideal for winter installation. So, because of all this, seam roofing coverings confidently remain on the list of the most popular among all materials for the design of side buildings.

Ruberoid

Roofing felt is laid on a continuous sheathing. Its advantage is that it is sold in rolls, and there will be no installation difficulties. However, there are several pitfalls here too.

- It should be borne in mind that the material consumption will be impressive. Roofing felt is laid in three layers, which are coated with bitumen mastic for better thermal and waterproofing.

- The service life of the material is 15 years, after which it will need to be dismantled.

- The material is mainly used for finishing flat roofs. Roofing felt coating cannot be called aesthetically attractive: when pitched roofs are sheathed with it, they are additionally covered on top with some material with better decorative properties.

Ruberoid for roofing is produced in four main categories, which differ according to the type of base.

- Rubemast gives the coating durability due to the fact that it is more flexible and less susceptible to cracking.

- Fiberglass ruberoid or steklomast has characteristics similar to rubemast, but it is based on fiberglass rather than construction cardboard.

- Roofing felt is practically not produced, since it lags far behind in quality, but in terms of production price it is on par with other types.

- Euroroofing material has a complex structure. This material is the newest of all, and its qualities greatly exceed those of traditional roofing felt coatings.

Polycarbonate

This variety is of greatest interest due to its unusual appearance. The peculiarity of polycarbonate roofs is that they are transparent. Depending on which type of polycarbonate is chosen, the degree of transparency varies. Thus, the surface can be from slightly cloudy to practically impervious to light. Based on their structure, there are monolithic and cellular polycarbonate slabs. The first option is cheaper, but the second does not require additional thermal insulation.

Polycarbonate is resistant to all kinds of influences, both physical and chemical. It is non-flammable, so it can be considered a fireproof material.

However, it is worth keeping in mind that if you plan to make a warm garage, polycarbonate will not work. Due to the installation of additional thermal insulation, all its decorative qualities will be lost, and the result will not please you as much as it could. If you need a warm garage, then it is better to make the roof from a cheaper material.

Slope angle

The installation of a roof involves complex calculations, including raising the roof. Regardless of whether a gable or single-pitch structure is chosen, lifting is mandatory. The only exception is flat roofs, but there is always a slight slope of a couple of degrees.

The height to which the roof needs to be raised is determined by many factors. An important detail is how exactly the slope will be located. note that It is optimal to place the slope on the windward side. It doesn’t matter whether the garage is closed from the wind by other structures or a fence - this rule is immutable.

In times of shortage of materials, outbuildings were built from the remains of boards and everything that was left after the construction of the house. Of course, this did not cause them to lose functionality, but they significantly spoiled the appearance of the site. The grouse garage is built as part of an architectural ensemble, made in the same style and color scheme. In this article we will tell you how to make a high-quality gable roof for a garage with your own hands, we will figure out how to draw up a project and carry out installation correctly.

A gable roof is a simple structure consisting of two inclined planes, called roof slopes. They rest on the outer walls of the garage and converge at the ridge connection, which is the highest point of the roof. The two slopes and the base of the roof form an isosceles triangle. This method of covering a garage has the following advantages compared to other options:

- Ensuring the independent removal of snow and rainwater from the roof. The inclined surface of the slopes of a gable roof facilitates the drainage of water and snow masses, due to which the load on the rafter frame does not increase, and the need to clean the roof of snow rarely arises. In regions with a lot of precipitation in winter, a gable garage roof is a real alternative to lean-to structures, which often collapse during snowfalls.

- Economical. To make a gable roof with your own hands, you need a few building materials. The lumber from which the rafter frame and roofing materials are made have an affordable price, so the total cost of covering a garage will not be much higher than the cost of constructing lean-to analogues of the same area.

- Easy to assemble. A separate savings item could be the refusal to involve professional workers in the construction of the roof, since even an inexperienced craftsman can correctly make a gable roof for a garage with his own hands.

- High energy efficiency. Thanks to its shape, a gable roof reduces energy losses when heating rooms. It is considered the most energy-efficient way to cover commercial buildings. Therefore, if you install heating in the garage, a do-it-yourself gable roof is the most correct option.

- Organization of storage. The garage, first of all, is reserved for the maintenance of cars and other equipment, however, it must have space for storing seasonal tools, wheels and spare parts. The gable roof allows you to organize spacious shelving in the attic; they are easily made with your own hands in accordance with the needs of the owners.

Note! A garage with a gable roof, unlike single-pitch ones, looks like an independent structure. It can be located not only near the house, but in any convenient place on the site. Experienced craftsmen recommend making slopes with a slope of 20-30 degrees and using the roofing material that was used for the house for covering in order to maintain a single design style.

Design

The first step in building a gable roof for a garage with your own hands is to create a project that reflects the main design parameters. To begin work, you need to determine three main characteristics: the height of the ridge, the slope of the slopes and the type of roofing. Calculations when creating a project are performed taking into account the loads placed on the frame elements. The total weight of the roof is calculated to determine how deep the foundation is required. To sketch a working diagram, you need to correctly make the following calculations:

Important! The choice of suitable roofing material depends on the angle of inclination of the slopes. A slope of 20-30 degrees, which most experienced roofers recommend for a garage roof, allows you to use soft tiles, corrugated sheets, slate or rolled materials as a covering. But metal tiles, popular for DIY construction, require a slope slope of 35 degrees or more.

Rafter frame

The basis of each gable roof is a rafter frame, a set of elements that ensure the stability and stability of the roof structure. The garage roof is built on the basis of rafters made of coniferous wood impregnated with antiseptic and fire-resistant substances. Depending on the layout of the building, the weight and coverage area of the roofing material, 2 different types of rafter systems are used:

Note! When calculating the rafter system, the weight of its elements is taken into account, since it increases the load placed on the foundation. To avoid overloading, leading to deformation of the base of the building, a balance should be maintained between the thickness of the section and the number of rafters. The size of lumber is selected in accordance with tables that take into account the length of the rafters and the pitch between them.

Installation

The most crucial moment if you are building a roof with your own hands is the installation itself. To avoid mistakes, it is better to sketch out a schematic drawing that reflects all the dimensions of the frame elements, the distance between them, and the method of fastening. The work is performed in the following order:

Note! If the garage premises will be heated, the slopes will be thermally insulated, as well. For this, non-flammable fiber insulation is used, for example, basalt wool or expanded polystyrene.

Video instruction

Car enthusiasts with extensive experience know very well that a perfectly made roof for a garage is very important, since it is not only the final stage of the entire construction, but also serves as protection from various atmospheric precipitations. Installing a roof is a complex process, so you must first become familiar with what kind of roofs are made on garages and choose the right roofing covering.

What types of garage roofs are there?

The roof for a garage can be varied, so you must initially decide on its design. In many cases, it is possible to replace one type of roof with another, but this involves additional expense and worry. That is why it is better to make the right choice at the initial stage of roof construction.

Before choosing one of the types of roof frames, you should decide on its load-bearing characteristics, the size and shape of the box, and then consider one of the presented roof design options.

Features of a pitched roof device

A pitched roof is the simplest type of structure, which is in great demand today, since it has no analogues of similar cost. To equip such a roof, you do not need to use special building materials, special equipment or have deep knowledge in the field of design.

A shed roof is the simplest and cheapest structure for covering a garage.

Features of the construction of a pitched roof are as follows:

Two boards connected along the wide side are often used as rafter legs, but the best option is to use beams made of metal or wood with a cross-section of 50*150 mm.

A pitched roof consists of the following parts:

- the base of the roof is the rafter system to which all other constituent elements are attached;

- sheathing is a support for the roof covering;

- elements that strengthen the rafter system;

- insulating materials that protect the structure from water and retain heat inside the structure;

- directly covering the garage roof.

The upper ends of the garage with a pitched roof must have a mauerlat or logs that support the rafters. They are attached to the walls using wire anchors. The anchors themselves can be embedded in the masonry or driven into the wall.

Such a structure can be covered with any type of roofing material: roofing felt, corrugated sheeting, soft tiles, etc.

How is a gable roof constructed?

A gable roof is installed over the garage if an attic is needed. The most common gable roof gable design is an isosceles triangle.

The rafter system of a gable roof can be made in the following options:

Installing a gable roof is very simple, since its base consists of several rafters of identical sizes. The installation of the frame rafters is done sequentially, and then they are connected at the very top of the roof.

The roof support is the walls of the building. To correctly calculate the size of the ridge and rafters, you need to know not only the angle of inclination of the roof, but also the dimensions of the building. To accurately make a canopy, you need to add about half a meter to the length of the rafters.

Installation of a gable roof begins with the arrangement of trusses, which are assembled on the ground according to a template. The Mauerlat is installed around the perimeter of the building, and then it is attached to the wall using anchors. A layer of roofing felt is made between the Mauerlat and the wall.

Characteristic features of a sloping roof

A broken roof is a structure with numerous broken lines. In principle, this is a type of gable roof that allows you to create an additional room on the attic floor.

There are the following types of broken roofs:

The reliability of the structure and its comfort depend on the type of roof chosen. However, sloping hipped roofs are becoming most popular today, since they ideally combine two features: the effective use of additional space and the low complexity of installing the rafter system. This approach involves obtaining full-fledged living quarters with small financial investments.

The installation of a sloping hipped roof of the garage allows you to create full-fledged living quarters on the second floor

The installation of a sloping hipped roof of the garage allows you to create full-fledged living quarters on the second floor To build a sloping roof, it is necessary to make a fairly dimensional structure of the rafter system, however, during its construction, modular installation methods can be used, so it is not necessary to use different lifting equipment. The rafter system and racks are cut at the desired angle in those places where there are fractures in the slopes. To secure the knots, you need to use “kerchiefs” made of plywood with a maximum thickness of 2 cm.

This design of a hipped roof is perfect for small-sized garages, where it is not possible to construct a sloping roof of a more complex shape. For buildings with large areas, a different rafter system is installed.

Used garage roof

An operable roof is a flat-shaped structure that has a special coating. A similar structure can be built over the entire area of the building or over some part of it.

The roof in use is conventionally divided into the following types:

The construction of such a roof must comply with the standards specified in SNiP, since the operating time of the roof depends on the correctness of the selected materials, the calculations performed, and the consideration of loads.

Typically, the roof structure has a multi-layer structure, and it is done in this way:

- rigid base;

- mandatory vapor barrier layer;

- insulation;

- screed at the correct angle;

- waterproofing layer;

- protective separator;

- finishing coating.

An existing roof can also be constructed using granite gravel (fraction 25/32 mm), which is laid on geotextiles. In order for the roof to operate normally, gravel is laid with a thickness of at least 50 mm. Geotextiles in parallel with gravel will make the coating more stable.

The undeniable advantages of a sliding roof for a garage

Today, mobile sliding roofs, which have many advantages over traditional roofs, are of great interest.

According to its design, a sliding roof can be of the following type:

Based on functionality, sliding roofs are divided into:

- seasonal (the structure moves only during a certain period, usually in summer);

- permanent (used throughout the year);

- temporary (used for mobile light structures).

In addition, a sliding roof can be not only permanent, when the entire structure or a specific part of it is covered, but also attached over various buildings to the main house. Among other things, a retractable roof can also be designed over other free-standing buildings, for example, greenhouses, greenhouses or observatories.

The main elements of a sliding roof are load-bearing aluminum profiles, which are manufactured with a variety of protective coatings in the form of:

- anodizing;

- powder paint;

- various enamels.

To give rigidity to the profiles, a steel pipe with a square cross-section is installed inside them. However, the most durable forms of sliding roof frames are considered to be:

- dome;

- arched;

- single-pitched with a slope angle of at least 45 o.

For other types of roofs, which have a slope angle of up to 45 o, only reinforced coverings and profiles are used.

The highest quality and most effective options for arranging a retractable roof are considered to be coverings made of plexiglass, triplex or tempered glass. This type of panel can withstand hail up to 14 mm.

What types of materials are used for garage roofs?

A garage roof can be built from a variety of building materials, and their cost depends on the “thickness” of your wallet, and installation methods depend on the time you have. Therefore, it is worth thinking carefully about the type of roofing material for the garage.

A fairly popular and well-known material among consumers, which is affordable and easy to use. One roll is enough to cover 10 m2 of roofing and forget about it for 15 years. The main advantage of roofing felt is that this coating is inexpensive and durable, but for its use it is necessary to make a sheathing, as well as a rigid frame.

Ruberoid is one of the most inexpensive and popular materials for covering garage roofing

Ruberoid is one of the most inexpensive and popular materials for covering garage roofing Waterproofing is considered high-quality, provided that it is made of at least four different layers, and different types of roofing material are used.

Corrugated sheet

This is a modern material that is replacing slate, since the service life of corrugated sheets exceeds half a century. When deciding how to cover your garage roof, consider purchasing load-bearing wall material of the NS brand. The wavy profile of the sheet is made using cold rolling. All types of corrugated sheets have an identical wavy trapezoidal shape, but the size and height of the material differs for all brands.

Corrugated sheeting is one of the most popular materials for garage roofing because it is lightweight and lasts at least 50 years

Corrugated sheeting is one of the most popular materials for garage roofing because it is lightweight and lasts at least 50 years Corrugated sheeting is a durable, fireproof, as well as water and soundproof roofing material that meets government standards. Its advantage is its reusability.

Slate

Traditional slate is often used for garage roofing, as its service life is about 40 years at a moderate cost. The material is an asbestos-cement board, which is quite simple to install - holes are drilled into which galvanized nails are driven with an allowance of a couple of millimeters. Further, the installation of this material is carried out identically to the installation of a roof made of corrugated sheets with the only difference - the corners of the internal spans are cut off.

Slate is laid on the garage roof in the same way as corrugated sheeting and secured with special slate nails

Slate is laid on the garage roof in the same way as corrugated sheeting and secured with special slate nails Roof tiles

The garage roof can also be made of cement-sand or ceramic tiles. These types of natural coatings last approximately 100 years and are characterized by resistance to ultraviolet radiation, fire resistance and the ability to withstand a variety of temperature changes. In addition, the tiles perfectly absorb noise, do not retain static voltage and have low thermal conductivity.

To lay tiles on a gable roof, special locks are used on each product

To lay tiles on a gable roof, special locks are used on each product If a roof is being built with a slope of about 12 degrees, then metal tiles are the ideal option. The flooring is made of galvanized steel 0.6 mm thick, which is coated with a polymer composition. To give the material its shape, it is stamped. Metal tiles are sold in a varied palette of colors.

Metal tiles are laid in large sheets, often corresponding in length to the dimensions of the slope

Metal tiles are laid in large sheets, often corresponding in length to the dimensions of the slope Seam roof

Metal is the lightest building material, allowing you to save money when installing the frame. Of course, when maintaining a metal structure, you will have to spend a lot of money, but this material is suitable for any type of roof. For example, when planning to build a metal roof, when arranging it, you can only get by with sheathing, which is made of beams.

To create a seam garage roof, special tools are used to form a sheet fastening profile

To create a seam garage roof, special tools are used to form a sheet fastening profile Installing a seam structure requires the use of special equipment and the involvement of professionals, since even minor “punctures” in the calculations will lead to distortions, which are much more difficult to eliminate than to immediately build a roof correctly.

How and how to insulate a garage roof

Every motorist dreams of a warm garage, and making the roof insulated is quite simple.

In modern construction, the garage roof is insulated in combination, that is, traditional insulation is combined with a heat insulator that reflects light and does not allow infrared radiation to pass through. However, in some cases such costs may be unreasonably high, for example, if the building is detached. Then use classic materials such as:

- Mineral wool. It has excellent technical characteristics. It is used only with hydro- and vapor barrier material, which protects mineral wool from water. In addition, mineral wool is quite affordable.

Mineral wool is inserted into the cells between the rafters and secured with wire or fishing line before the final ceiling covering is laid

Mineral wool is inserted into the cells between the rafters and secured with wire or fishing line before the final ceiling covering is laid - Glass wool. This material is cheaper than other insulation materials, but has a low degree of fire resistance. If you plan to make a pitched roof, then it is better to buy a special type of glass wool, which has a high density structure. This material is produced in rolls with a width equal to the normal distance between the rafter legs.

Glass wool is one of the most inexpensive and accessible materials for roof insulation

Glass wool is one of the most inexpensive and accessible materials for roof insulation - Styrofoam. This is a waterproof material, which in its thermal insulation characteristics is similar to mineral wool. Polystyrene foam is a flammable insulation material, but the PBS-S brand with the addition of fire retardants has the property of self-extinguishing. Due to these features of the material, it is used as insulation for garage roofs. In addition, it does not rot, mold and mildew do not form on it.

Laying foam plastic in the sheathing of a garage roof does not require special skills

Laying foam plastic in the sheathing of a garage roof does not require special skills - Penoizol. It is a liquid foam, but with better performance. It is resistant to fire and water, hardens when placed in a confined space, and forms an ideal seamless coating. With all this, penoizol is cheaper than any sheet foam, and its service life is about 40 years without loss of characteristics.

To insulate the roof with foam insulation, it is necessary to use special equipment for spraying

To insulate the roof with foam insulation, it is necessary to use special equipment for spraying

You can also use traditional options for insulating a garage roof, for example, using sawdust, but they cannot be compared with modern materials.

The garage space is an object with a high probability of fire, so it is necessary to purchase insulation with improved fire resistance characteristics.

Insulating the garage roof from the inside

Required tools:

- special buttons or furniture stapler with staples;

- vapor barrier film;

- carpentry tools;

- self-adhesive tape;

- waterproofing;

- insulation.

Thermal insulation of the roof from the inside is carried out as follows:

Such a cake is laid not only on wooden beam structures, but also on reinforced concrete slabs. Before installation, the beams are protected with sheet material, after which waterproofing is attached to it, then insulation and vapor barrier.

Do not allow the waterproofing film to come into contact with the insulation; there must be a certain distance between these materials for ventilation. Direct contact is only allowed if a superdiffusion membrane has been used.

Video: how to insulate the inside of a garage roof

We insulate the garage roof from the outside

From the outside, the roof is insulated during the construction stage, since it is not very convenient to open a completed building in order to correct shortcomings. Please note the presence of a vapor barrier, which must be installed on the side of the room. This way you can prevent not only re-condensation of vapors, but also avoid unpleasant leaks. How to insulate a garage roof from the outside:

Video: how to insulate a garage roof from the outside

How to repair a garage roof

Leaking is the main nuisance that a garage roof brings, and the reasons for this may be:

- exhaustion of the strength resource during operation;

- negative impact of weather;

- incorrect roof installation;

- mechanical damage due to careless cleaning of the roof from snow cover;

- low quality finishing material;

- neglect of the installation of waterproofing;

- violation of installation standards when using roofing material.

Leaks must be eliminated at the stage of mold or wet spots appearing. Initially, it is worth checking the joints and joints, then the integrity of the roof for holes, chips or other damage. In addition, it is necessary to eliminate various types of blockages, such as dry leaves that clog the corners of the roof and accumulate moisture.

The method of eliminating a leak depends solely on the amount of damage and the characteristics of the roofing material. Partial repairs can be carried out for small-piece and soft roofing materials. The scope of repair work for panel and sheet material depends only on the complexity of the structure and its damage.

Using roofing felt, you can quickly and inexpensively completely repair your garage roof and get rid of leaks

Using roofing felt, you can quickly and inexpensively completely repair your garage roof and get rid of leaks When preparing drawings and a garage roof project, immediately include in the estimate an extra 10% for other expenses that are difficult to foresee.

Video: how to repair a garage roof

High-quality construction of a garage roof is the best option to minimize your costs if you have the necessary knowledge in construction. The choice of material and tools is of great importance when arranging a roof. Just read the necessary information and you can do all the work yourself. We wish you success!