Single core wires.

Types single-core wires.

Electric wire - a cable product containing one or more twisted wires or one or more insulated cores, on top of which, depending on the installation and operating conditions, there may be a light non-metallic sheath, winding and (or) braid made of fibrous materials or wire, and is not generally intended for , for laying in the ground.

Copper or aluminum wire is usually used as a conductor. The core may consist of several wires (usually twisted) - multi-wire core.

Not to be confused with stranded wire, where each core is an independent wire.

The wire consists of the following elements:

1. Conductive vein electric current(copper or aluminum).

2. Insulating shell.

Single core solid wire.

Solid Stranded Wire

Cable - a structure of one or more conductors (cores) isolated from each other, or optical fibers, enclosed in a shell.

Wire classification:

1. winding wires:

copper wires (grades PEV, PEL, PETV-2, PET-155, LELO, LENK, etc.);

high resistance wires (constantan, manganin, nichrome);

2. installation wires (brands MGTF, MGTFE, etc.);

3. connecting wires (brands PVS, PRS, Ball Screw, etc.);

4. output wires (brands PVKV, RKGM, VPP, etc.);

5. wires for rolling stock (brands PPSV, PPSRN, PS, etc.);

6. automobile wires (brands PGVA, PGVAE, PVAM, etc.);

7. aviation wires (brands BPVL, BIF, BIN);

8. installation wires (grades APV, PV1, PV2, PV3, etc.);

9. communication wires (brands PVZh, PPZh, PKSV, etc.);

10. insulated wires for air lines(brands SIP-1, SIP-2, SIP-3, etc.);

11. bare wires (grades M, A, AC, etc.);

12. wires for geophysical work (grades GSP, GPMP, etc.);

13. heat-resistant wires (brands PVKV, PAL, PVKF);

14. thermoelectrode wires (grades SFK-KhK, PTV-KhK, PTP-KhK, etc.);

15. warm-up wires (brands PNSV, PNPZh, NO-1, etc.).

Parameters of single-core wires

The wires include the following parameters: cross-sectional area, operating voltage and frequency, core material, type of insulation, flexibility, heat resistance, operating temperature range, relative humidity air during operation, wire bending radius, wire color, etc.

Calculation of cable cross-section

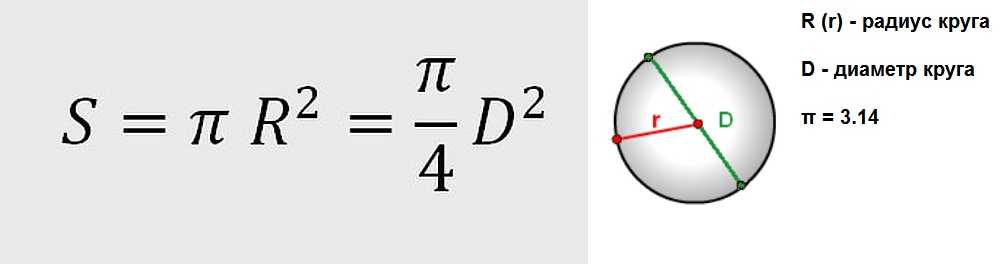

The cross-section of the wire can be determined by the diameter of the core. In practice, the diameter of the core without insulation is most often measured with a caliper or micrometer. Knowing the diameter of the core, it is quite easy to determine the cross-section of the wire. To do this, you need to use the wire cross-section formula, which coincides with the usual school formula for calculating the area of a circle, which is given below.

Calculation example

The warehouse received a single-core single-wire wire PV-1 without markings with a core diameter of 3.57 mm. Let's determine the cross-section of the wire by diameter:

Skr=3.14*3.57^2/4=10 mm 2

The nearest standard section is 10mm 2. Thus, the PV1 10 wire was delivered to the warehouse.

How to determine the cross-section of a stranded wire by its diameter?

If the wire is multi-wire, then you need to fluff it up and count the number of wires in the bundle. Determine the diameter of one wire, calculate its cross-sectional area s, then determine the cross-sectional area of the entire wire by adding up the areas of all the wires.

For example: the number of wires in a bundle is 37 pieces; diameter of each wire d = 0.3 mm.

Let us determine the cross-sectional area of one wire.

s = 0.785*d² = 0.785 *0.3*0.3 = 0.070 mm 2

Cross-sectional area of the entire stranded wire

S = 37*s = 37*0.070 = 2.59 mm 2

Managers of electrical goods companies do not always give the correct answer to the question of choosing a cable cross-section for current, and do not take into account a number of factors.

Calculation of cable cross-section for electrical wiring installation

For example, when the cable heats up (during prolonged passage of the rated current), and in the presence of other cables, power cable can heat up by tens of degrees.

These circumstances will significantly worsen the insulation resistance. In this case, the cable must have a current reserve of up to 30%. Also, the choice of cross-section depends on where the cable is laid, whether it goes through the air, or in a cable channel or groove.

Possible cable and wire losses

Considering elevated temperature summer, meaning maximum current you need to multiply by 0.65 those readings that appear in table No. 2 and No. 3. Also, in the rules for electrical installations there is a reducing factor for the number of cables laid in trays, and a factor that depends on the ambient temperature.

The length of the cable and wire also incurs some electricity losses. The longer the cable, the higher the resistance and, accordingly, the higher the losses.

Cable losses cannot be more than 5%. Such electricity losses can be calculated by knowing rated current and cable resistance.

Cable loss calculation

Load moment copper cable selected with a cross-section of 1.5 with a length of 18 meters and a load of 2 kW will have 18 x 2 = 3 6 or 2%. When losses are more than 5%, you need to use an electrical cable with a larger cross-section.

In the case of a three-phase electrical network, the load torque must be multiplied by 3, with symmetrical loads (or identical), the load torque is multiplied by 2 - this is for ideal symmetrical loads (when the currents in the phases are the same, and the current on the N core is zero) that can only be achieved with active loads.

|

Load moment, kW* m, for copper conductors in a two-wire line for a voltage of 220 V with a conductor cross-section S equal to: |

|||||||

Table 2 for selecting cable cross-section for open wiring electrical network

| Cable core cross-section, mm² | Cable core diameter, mm | Wiring with copper core | Wiring with aluminum core | ||||

| Current, A | Current, A | Power, kW at mains voltage 220 V | Power, kW at mains voltage 380 V | ||||

| 0,5 | 0,8 | 11 | 2,4 | — | — | — | — |

| 0,75 | 0,98 | 15 | 3,3 | — | — | — | — |

| 1,0 | 1,12 | 17 | 3,7 | 6,4 | — | — | — |

| 1,5 | 1,38 | 23 | 5,0 | 8,7 | — | — | — |

| 2,0 | 1,59 | 26 | 5,7 | 9,8 | 21 | 4,6 | 7,9 |

| 2,5 | 1,78 | 30 | 6,6 | 11,0 | 24 | 5,2 | 9,1 |

| 4,0 | 2,26 | 41 | 9,0 | 15,0 | 32 | 7,0 | 12,0 |

| 6,0 | 2,76 | 50 | 11,0 | 19,0 | 39 | 8,5 | 14,0 |

| 10,0 | 3,57 | 80 | 17,0 | 30,0 | 60 | 13,0 | 22,0 |

| 16,0 | 4,51 | 100 | 22,0 | 38,0 | 75 | 16,0 | 28,0 |

| 25,0 | 5,64 | 140 | 30,0 | 53,0 | 100 | 23,0 | 39,0 |

Table 3 selection of cable cross-section for hidden wiring electrical network

(in cable channel, pipe)

| Cable core cross-section, mm² | Cable core diameter, mm | Wiring with copper core | Wiring with aluminum core | ||||

| Current, A | Power, kW at mains voltage 220 V | Power, kW at mains voltage 380 V | Current, A | Power, kW at mains voltage 220 V | Power, kW at mains voltage 380 V | ||

| 1 | 1,12 | 14 | 3,0 | 5,3 | — | — | — |

| 1,5 | 1,38 | 15 | 3,3 | 5,7 | — | — | — |

| 2,0 | 1,59 | 19 | 4,1 | 7,2 | 14 | 3,0 | 5,3 |

| 2,5 | 1,78 | 21 | 4,6 | 7,9 | 16 | 3,5 | 6,0 |

| 4,0 | |||||||

| 6,0 | 2,76 | 34 | 7,7 | 12,0 | 26 | 5,7 | 9,8 |

| 10,0 | 3,57 | 50 | 11,0 | 19,0 | 38 | 8,3 | 14,0 |

| 16,0 | 4,51 | 80 | 17,0 | 30,0 | 55 | 12,0 | 20,0 |

| 25,0 | 5,64 | 100 | 22,0 | 38,0 | 65 | 14,0 | 24,0 |

| 35,0 | 6,68 | 135 | 29,0 | 51,0 | 75 | 16,0 | 28,0 |

Thus, for three-phase network also in case of losses, it is necessary to increase the cross-section of the cable; for cables with operating currents equal to 0.5 relative to the maximum, an amendment is needed that takes into account not 5% losses, but 4% losses of electricity.

When calculating cable and wire losses, you also need to take into account the number of connections, since they also produce significant losses.

How to choose the cable cross-section when installing electrical wiring?

The choice of wire cross-section in this case depends on the permissible current density delta, which is measured in A/mm². This current density shows the load on the wire, and depends on the operating conditions, which can vary from 2 A/mm² - for closed wiring and up to 5 A/mm² if the wires are in fireproof insulation. Required diameter wires can be determined by the selected current and its density values using the following formula:

In the case of electrical wiring, the current density delta is taken ( Δ ) equal to 2 A/mm², and then the above formula is converted into:

![]()

The wire cross-section can be found using the following formula:

![]()

This current density value of 2 A/mm² is selected with a large margin because, electrical wiring walled up in the wall, and remove the burnt electrical wiring from under the plaster and finishing walls, very difficult.

The cross-section of the cable and wire for closed wiring is taken 30% larger than for open wiring, since in hidden version The cable is practically not cooled.

In theory, the diameter of the conductors should correspond to the declared parameters. For example, if the marking indicates that the cable is 3 x 2.5, then the cross-section of the conductors should be exactly 2.5 mm 2. In fact, it turns out that the actual size may differ by 20-30%, and sometimes more. What does this mean? Overheating or melting of insulation with all the ensuing consequences. Therefore, before purchasing, it is advisable to find out the size of the wire in order to determine its cross-section. We will find out further how to calculate the wire cross-section by diameter.

How and with what to measure the diameter of a wire (wire)

To measure the diameter of the wire, a caliper or micrometer of any type (mechanical or electronic) is suitable. It’s easier to work with electronic ones, but not everyone has them. You need to measure the core itself without insulation, so first move it aside or remove a small piece. This can be done if the seller allows it. If not, buy a small piece to test and take measurements on it. On a conductor stripped of insulation, measure the diameter, after which you can determine the actual cross-section of the wire from the found dimensions.

Which meter in this case is it better? If we talk about mechanical models, then a micrometer. Its measurement accuracy is higher. If we talk about electronic options, then for our purposes they both give quite reliable results.

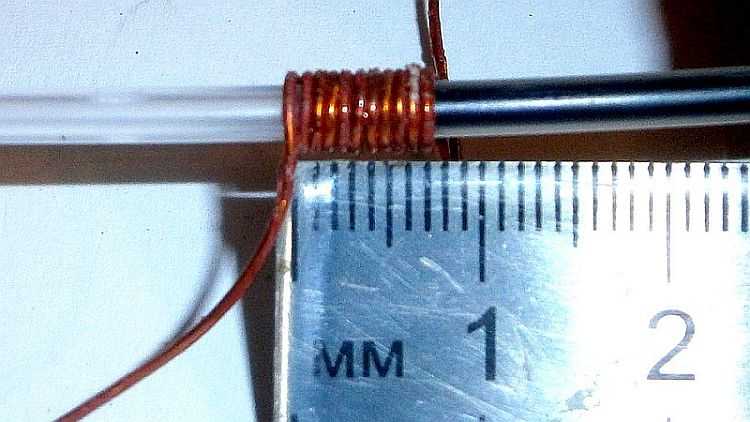

If you don't have a caliper or micrometer, take a screwdriver and a ruler with you. You'll have to strip a fairly decent piece of conductor, so you'll hardly be able to do without buying a test sample this time. So, remove the insulation from a 5-10 cm piece of wire. Wind the wire around the cylindrical part of the screwdriver. Lay the coils close to each other, without a gap. All turns must be complete, that is, the “tails” of the wire must stick out in one direction - up or down, for example.

The number of turns is not important - about 10. You can have more or less, it’s just easier to divide by 10. Count the turns, then apply the resulting winding to the ruler, aligning the beginning of the first turn with the zero mark (as in the photo). Measure the length of the section occupied by the wire, then divide it by the number of turns. You get the diameter of the wire. It's that simple.

For example, let's calculate the size of the wire shown in the photo above. The number of turns in this case is 11, they occupy 7.5 mm. Divide 7.5 by 11, we get 0.68 mm. This will be the diameter of this wire. Next, you can look for the cross section of this conductor.

We are looking for the wire cross-section by diameter: formula

The wires in the cable have a circular cross-section. Therefore, when calculating, we use the formula for the area of a circle. It can be found using radius (half the measured diameter) or diameter (see formula).

Determine the cross-section of the wire by diameter: formula

For example, let's calculate the cross-sectional area of the conductor (wire) based on the size calculated earlier: 0.68 mm. Let's use the radius formula first. First we find the radius: divide the diameter by two. 0.68 mm / 2 = 0.34 mm. Next, we substitute this figure into the formula

S = π * R 2 = 3.14 * 0.34 2 = 0.36 mm 2

You need to calculate it like this: first we square 0.34, then multiply the resulting value by 3.14. We obtained a cross-section of this wire of 0.36 square millimeters. This is very thin wire, which is not used in power networks.

Let's calculate the cable cross-section by diameter using the second part of the formula. It should be exactly the same value. The difference may be in thousandths due to different rounding.

S = π/4 * D 2 = 3.14/4 * 0.68 2 = 0.785 * 0.4624 = 0.36 mm 2

In this case, we divide the number 3.14 by four, then we square the diameter and multiply the two resulting numbers. We get a similar value, as it should be. Now you know how to find out the cable cross-section by diameter. Whichever of these formulas is more convenient for you, use that one. There is no difference.

Table of correspondence of wire diameters and their cross-sectional area

You don’t always want or have the opportunity to make payments in a store or on the market. In order not to waste time on calculations or to avoid making mistakes, you can use the table for the correspondence of diameters and cross-sections of wires, which contains the most common (normative) sizes. You can rewrite it, print it and take it with you.

| Conductor diameter | Conductor cross-section |

|---|---|

| 0.8 mm | 0.5 mm2 |

| 0.98 mm | 0.75 mm2 |

| 1.13 mm | 1 mm2 |

| 1.38 mm | 1.5 mm2 |

| 1.6 mm | 2.0 mm2 |

| 1.78 mm | 2.5 mm2 |

| 2.26 mm | 4.0 mm2 |

| 2.76 mm | 6.0 mm2 |

| 3.57 mm | 10.0 mm2 |

| 4.51 mm | 16.0 mm2 |

| 5.64 mm | 25.0 mm2 |

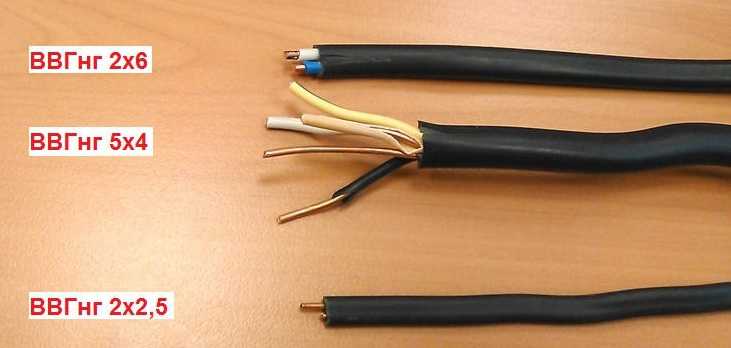

How to work with this table? As a rule, the cables have a marking or tag indicating its parameters. The cable marking, number of cores and their cross-section are indicated there. For example, VVNG 2x4. We are interested in the core parameters and these are the numbers that appear after the “x” sign. In this case, it is stated that there are two conductors having a cross section of 4 mm 2. So we will check whether this information corresponds to reality.

To check, measure the diameter using any of the described methods, then check the table. It states that with such a cross-section of four square millimeters, the wire size should be 2.26 mm. If your measurements are the same or very close (there is a measurement error, since the devices are not ideal), everything is fine, you can buy this cable.

But much more often, the actual diameter of the conductors is much smaller than the declared one. Then you have two options: look for a wire from another manufacturer or take a larger cross-section. Of course, you will have to overpay for it, but the first option will require a fairly long period of time, and it is not a fact that you will be able to find a cable that complies with GOST.

The second option will require more money, since the price significantly depends on the declared cross-section. Although, it’s not a fact - a good cable made according to all standards may cost even more. This is understandable - the cost of copper, and often also for insulation, subject to technology and standards, is much higher. That’s why manufacturers cheat by reducing the diameter of the wires in order to reduce the price. But such savings can turn into disaster. So be sure to take measurements before purchasing. Even trusted suppliers.

And one more thing: inspect and feel the insulation. It should be thick, continuous, and have the same thickness. If, in addition to changing the diameter, there are also problems with insulation, look for a cable from another manufacturer. In general, it is advisable to find products that meet the requirements of GOST, and not made according to specifications. In this case, there is hope that the cable or wire will serve for a long time and without problems. This is not easy to do today, but if you are breeding or, quality is very important. Because it’s probably worth looking for.

How to determine the cross-section of a stranded wire

Sometimes stranded conductors are used - consisting of many identical thin wires. How to calculate the cross-section of the wire by diameter in this case? Yes, exactly the same. Carry out measurements/calculations for one wire, count their number in the bundle, then multiply by this number. So you will find out the cross-sectional area of the stranded wire.

The cross-section of the electrical wiring depends on the material and load. Aluminum is now rarely used. All that remains is copper and composite material– aluminum-copper, from which electrical wire is produced. The size of the cross-section is not always known from the following reasons: there are no markings, the diameter of the core does not correspond to that specified in the accompanying documents.

What types of cables and wires are there?

Wire and cable

To refer to a conductor, two concepts are often used: wire and cable. They are often confused, although they have some differences.

The wire is a single conductor and is divided into 2 groups: a solid wire with or without insulation, and a flexible wire woven from thin wires.

The cable consists of a group of cores enclosed in separate and general insulation. The veins can be solid (VVG, VVGng, NYM) or woven (PVS).

Conductor materials

The amount of energy transferred depends primarily on the material of the conductor. It can be one of the following non-ferrous metals:

- Copper – small electrical resistance; high strength and elasticity; easy to weld and solder; low contact resistance; high cost.

- Aluminum is lightweight and cheap material; electrical conductivity is 1.7 times lower than that of copper; easily deformed; high contact resistance of oxidized surfaces; welding is possible in an inert gas environment, and soldering requires special solders and fluxes.

- Aluminum copper – a composite with an aluminum base and copper coating; conductivity is slightly lower than that of copper; cable and wire have less weight; inexpensive material.

The methods for determining the cross-sectional area of wires and cores are not much different. First of all, you need to measure the diameter of the conductors. They provide reliable insulation that must be removed. There are 3 ways to do this.

Measuring instruments

The instruments used are a micrometer and a caliper. Usually used mechanical devices, although there are also electronic ones with a digital display. One of these devices will always be found among the home owner's tools.

The most commonly used caliper is suitable for measuring wires in an active network, for example, in a panel or socket. The cross-sectional area of the conductor is found as follows:

S Kr = 3.14D 2 /4,

where D is the diameter of the wire.

The diameter is measured at least three times, when turning the cable by 120 0. The average value is taken as the result.

Measuring wire diameter with a caliper

In the absence of instruments, the diameter of the wire is determined using a ruler. To do this, the insulation is cleaned from the core and wound tightly around a pencil (at least 15 turns). Then measure the length of the winding and divide it by the number of turns. The coils must be laid evenly and adjacent to each other without gaps.

Measuring wire diameter using a ruler

Take several measurements from different sides. Then the result will be more accurate. Wires of great thickness cannot be wound onto a pencil, and a check in a store can only be done after purchasing the product. The cross-sectional area can be determined using a formula or using a table.

- Aluminum is easy to distinguish from copper, which has a characteristic rich color. Instead, there may be an alloy of metals, which is easy to determine by appearance.

- If there is any doubt about the material and age of the conductor, a larger cross-section is taken. The correctness of the choice is then checked by heating the wire at the rated load. If it does not heat up, then the calculation is correct.

- The cable contains several cores. To select the required section, the diameter is determined individually for each of them, and then combined with each other required quantity to get the required area:

S total = S 1 + S 2 +…+S n,

S total – total cross section,

S 1, S 1, S n – cross sections of individual conductors.

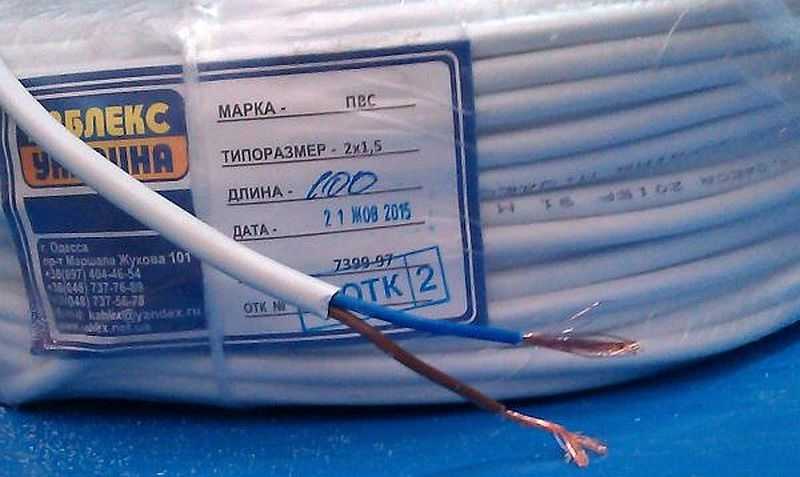

Stranded wire

The PVS cable for connecting power tools and electrical appliances is made flexible, since all the cores are stranded. Measuring the diameter of the harness at the same time will give an incorrect result, since there are air gaps inside. Correct Principle The calculation is the same as for the cable. The core should be fluffed up, count how many wires are in it, and then measure the diameter of one of them. Knowing their total number in the vein, you can calculate the total cross-section using the previous formula. It’s best to take measurements using a micrometer. It is more convenient to use, since the caliper easily presses through thin wires.

Segment cable

A cable with a cross-section of up to 10 mm 2 is always made round. They can always provide the household needs of an apartment or private house. With a larger cable cross-section, the input cores from the external power supply are made segmental, which is difficult to calculate. It is convenient to determine the cross-sectional area when there is a ready-made calculation table. To do this, you must first measure the height and width of the segment.

Table for calculating the area of a cable core segment

| Cable | Sectional area of the segment, mm2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 35 | 50 | 70 | 95 | 120 | 150 | 185 | 240 | ||

| Three-core sector single-wire, 6(10) kV | V | 5.5 | 6.4 | 7.6 | 9 | 10.1 | 11.3 | 12.5 | 14.4 |

| w | 9.2 | 10.5 | 12.5 | 15 | 16.6 | 18.4 | 20.7 | 23.8 | |

| Three-core sector stranded, 6(10) kV | V | 6 | 7 | 9 | 10 | 11 | 12 | 13.2 | 15.2 |

| w | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | |

| Four-core sector single-wire, up to 1 kV | V | - | 7 | 8.2 | 9.6 | 10.8 | 12 | 13.2 | - |

| w | - | 10 | 12 | 14.1 | 16 | 18 | 18 | - | |

Calculation of core cross-section

By power

The calculation method is preferable, since the documentation for the devices and on their labels indicate the amount of average and maximum power consumption. For wiring it is important to know extremely valid value. A washing machine can consume from tens of watts during rinsing to 2.5 kW during heating. In addition, there can be several consumers on one core. The total power is determined by summing all maximum values.

The average load in an apartment does not exceed 7.5 kW for single-phase network, where the voltage is 220 V. This includes all electrical appliances and lighting. They select the closest cable cross-section size in the direction of increasing power. For a copper core with a cross section of 4 mm 2 corresponds to 8.3 kW. The aluminum core has an area of 6 mm 2 per 7.9 kW.

When choosing the cross-section of each conductor, you should take into account the possible increase in load in the future. Therefore, they usually take the next largest area in the direction of increase.

In private homes, a three-phase power supply of 380 V is used, and most electrical appliances are not designed for this. You can create a voltage of 220 V by connecting via neutral wire With uniform distribution loads on all phases. Three-phase technology is also taken into account. These could be machines, pumps, heating boilers.

Table of cable cross-sections for current and power

| Current cross-section conductive cores, mm | Copper conductors of wires and cables | |||

|---|---|---|---|---|

| Voltage 220 V | Voltage 380 V | |||

| Current, A | Power, kW | Current, A | Power, kW | |

| 1,5 | 19 | 4,1 | 16 | 10,5 |

| 2,5 | 27 | 5,9 | 25 | 16,5 |

| 4 | 38 | 8,3 | 30 | 19,8 |

| 6 | 50 | 11 | 40 | 26,4 |

| 10 | 70 | 15,4 | 50 | 33 |

| 16 | 90 | 19,8 | 75 | 49,5 |

| 25 | 115 | 25,3 | 90 | 59,4 |

| 35 | 140 | 30,8 | 115 | 75,9 |

| 50 | 175 | 38,5 | 145 | 95,7 |

| 70 | 215 | 47,3 | 180 | 118,8 |

| 95 | 260 | 57,2 | 220 | 145,2 |

| 120 | 300 | 66 | 260 | 171,6 |

By current

Sometimes the power of a device is not known for the following reasons: there is no power value in the characteristics, but the rated current is indicated, there is no label and description.

Since the current and voltage are known, the power can be calculated as follows:

P = UI∙cosφ,

I – current strength, A;

U – applied voltage, V.

If the current value is not known, it can be measured by turning on the device in another location. When the power consumption is determined using the formula, the table makes it possible to immediately find out the required cable size. The table below also shows the dependence of the conductor cross-section on the current value.

By load

Cable calculation based on current load is necessary to protect against overheating. If the current is too large for the cable cross-section, overheating, melting and destruction of the insulation occurs.

Below the maximum permissible long-term load refers to the value of current that can be passed through the cable under installation conditions for a sufficiently long time without overheating. When calculating, all the powers of devices connected to certain wires are summed up. Then a load calculation is made for household networks:

I = P ∑ ∙K and /U – single-phase;

I = P ∑ ∙K and /(√3∙U) – three-phase;

P ∑ – total power of consumers;

Length

Extension cords typically need to be designed for long distances. In apartment conditions this is not required, since the length of the lines is short. But everywhere it is necessary to leave a reserve, especially for panels where protection is connected and careful laying of the wire is required.

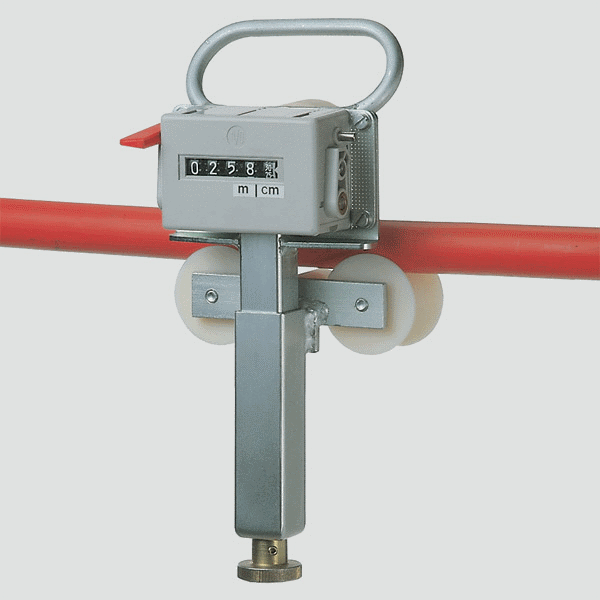

The cable is laid as follows:

- The locations of connections are marked: sockets, automatic machines, distribution boxes, switches.

- Distances are measured using a tape measure or a special hand-held length meter. It is more convenient to use, and the result is more accurate. Afterwards, the wire is cut off with a reserve.

- Laying and fastening of the wire is carried out in compliance with the requirements of the PUE.

Cable length meter

Any conductor has electrical resistance, which is influenced by factors:

- choice of material;

- section;

- length.

If the voltage drop exceeds 5%, then measures are taken to reduce it. If you choose a conductor with a larger cross-section, you can reduce the resistance of the section, determined from the formula:

p – resistivity(Ohm mm 2 /m);

R – total resistance wire section (Ohm);

S – cross-sectional area (mm 2);

L – length of the wire section (m).

When calculating, it should be taken into account that the current flows through one core, and the return occurs through the other. Therefore, the length L is doubled. Despite the fact that the resistance of the wire is small, it creates a significant voltage drop. If R = 0.5 Ohm, then with a current of 20 A the drop will be:

∆U = I R = 20 0.5 = 10 V.

In percentage terms it will be 10/220·100 = 4.5%. The loss value is close to the maximum permissible.

In a room, it is necessary to take into account the difference between power and lighting loads. For lamps, you can take a copper wire cross-section of 1.5 mm 2, but you need to be careful with sockets. They are most stressed in the kitchen and bathroom, where they constantly turn on the microwave, electric stove, washing machine, dishwasher, electrical appliances. They try to distribute the load evenly among the socket groups, and the wire is selected with a cross-section of 4 mm 2 or even more. The appropriate sockets and switches are installed for the current value.

Wire section. Video

The video below will tell you how to choose the most optimal wire cross-section for each specific situation.

Calculation of cable length and cross section - important process, not allowing for miscalculations. Must be taken into account greatest number factors, trusting only your own calculations. They must match what the reference table shows. Special requirements must be set for the quality of wiring materials and the characteristics of connected consumers.

You can often find electrical products in supermarkets without tags or identification marks. Among it there could easily be a coil of wire or cable. How do you know if the wire size is appropriate for your specific situation? The answer is simple - measure it or consult the seller.

Anyone who sells cables and wires can tell you what load they can withstand. In addition, inscriptions (numbers) are stamped on the wires, characterizing the cross-section and number of cores. But in real practice, not everything is as simple as it seems. The quality of cable products produced in lately has noticeably worsened.

Problems with the quality of manufactured wires

Many manufacturers of cable and wire products, trying to make more money, artificially reduce the thickness of the insulation and increase the diameter of the cable. By specifying a wire cross-section larger than in reality, the manufacturer saves a lot a large amount. For example, for the production of thousands of meters copper wire with a cross section of 2.5 mm2, 22.3 kg of copper is required, and when making a wire of 2.1 mm2, only 18.8 kg is required. This results in a saving of 3.5 kg of copper.

Another way to reduce the cost of products is to manufacture a conductor from low-quality raw materials. When adding cheap impurities, the current conductivity decreases, therefore, cable length calculations must be changed.

Why do you need to calculate the cable load?

This question often arises when installing wiring in an apartment or home. First, all planned loads are considered, and then the required wire cross-section is determined. Then it is purchased required material in the store and installing electrical wiring in the house.

As a result of operation new wiring first, the machine on the electrical panel “knocks out”, and then damage to the wire is detected. Moreover, it often turns out to be completely melted, as a result of which a short circuit occurs. It turns out that the calculations were made incorrectly, and how can you find out the minimum permissible value of the wire cross-section in this case?

To avoid serious overloads, it is necessary to calculate how much electrical appliances in the apartment will be activated simultaneously. Among the most powerful household appliances, which are usually used at home when preparing food and creating our comfort, can be distinguished:

- electric stove;

- air conditioner;

- microwave;

- electric kettle;

- iron;

- washing machine and dishwasher;

- coffee grinder;

- vacuum cleaner.

Power consumption of this household appliances ranges from 1 to 2 kilowatts (except for electric stoves).

Important! If the cross-section of the wire is indicated incorrectly (underestimated), then when using it, it is natural for large overloads to occur, which lead to a fire in the wiring.

How to calculate?

Experienced electricians can “by eye” determine the wire cross-section with great accuracy. To the ordinary person this is much more difficult to do. Therefore, it is best to calculate the cable cross-section by diameter right in the store. At least it will be much cheaper than eliminating the consequences short circuit due to an overload in the electrical network.

Let's try to do this on specific examples using arithmetic formulas of school mathematics.

Everyone roughly understands what a wire cross-section is. If you bite it across with wire cutters, you can see the round cross-section of a copper or aluminum core. It is measured using a standard mathematical formula: as the area of a circle. Where r is the radius of the circle, squared and multiplied by the constant “pi” (π=3.14).

How larger diameter cable/wire, the more current can pass in a certain amount of time. And, accordingly, the more energy consumed by electrical appliances, the larger the cross-section of the wire should be.

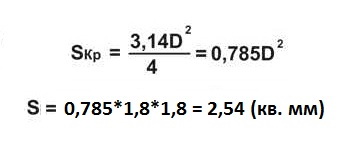

From the simplified formula Scr = 0.785d2 it is clear that to calculate the cross-sectional area you need to know the exact diameter of the wire. To do this, it is necessary to remove the insulation from the core.

Calculation for stranded wire

Stranded wire (stranded) consists of single-core wires twisted together. Anyone who is even a little familiar with mathematics understands perfectly well that it is necessary to count the number of these delays in stranded wire. After this, the cross-section of one thin wire is measured and multiplied by their total number. Let's consider the following options.

Calculation using a caliper

The measurement is carried out with a caliper with a conventional scale (or micrometer). U experienced craftsmen This tool is always at hand, but not everyone is a professional electrician.

To do this, using the VVGng cable as an example, cut the thick sheath with a knife and spread the wires in different directions.

Then select one core and strip it with a knife or scissors. Next, measure this core. The size should be 1.8 mm. Please refer to the calculations to prove the measurement is correct.

The resulting figure of 2.54 mm2 is the actual cross-section of the core.

Measuring with a pen or pencil

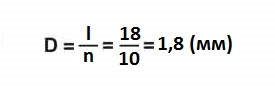

If you don’t have a caliper at hand, you can use improvised methods using a pencil and ruler. First, take the wire to be measured, strip it and wind it around a pencil or pen so that the turns lie close to each other. The more turns, the better. Now let's count the number of wound turns and measure them total length.

For example, we got 10 turns with a total winding length of 18 mm. It is easy to calculate the diameter of one turn; to do this, divide the total length by the number of turns.

As a result of all the calculations made using the formula, you will obtain the required diameter of the core. In this case it is 1.8 mm. Since the diameter of one core is known, it is not difficult to calculate the cross-section of the entire VVGng wire using the already known formula.

You can see that the results were equal.

Using tables

How can you find out and measure the cable cross-section if you don’t have a caliper, a ruler, or a micrometer at hand? Instead of racking your brains over complex mathematical formulas, just remember that there are ready-made tables of values for measuring cable cross-section. There are, of course, very complex tables with many parameters, but, in principle, to begin with it is enough to use the simplest of the two columns. The first column contains the diameter of the conductor, and the second column contains ready-made values for the wire cross-section.

Conducting cross-section table for closed wiring

Conducting cross-section table for closed wiring There is another “approximate” method that does not require measuring the thickness of individual wires. You can simply measure the cross-section (diameter) of the entire thick scroll. This method is usually used by experienced electricians. They can find out the cable cross-section both “by eye” and with the help of tools.